Board edge graphical tool manufacturing method preventing electrostatic spraying board from falling off

A technology of electrostatic spraying and production methods, which is applied in the fields of printed circuit manufacturing, electrical components, printed circuits, etc., can solve the problem that the clip cannot be clamped and fixed tightly, and achieve the effect of avoiding board falling and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

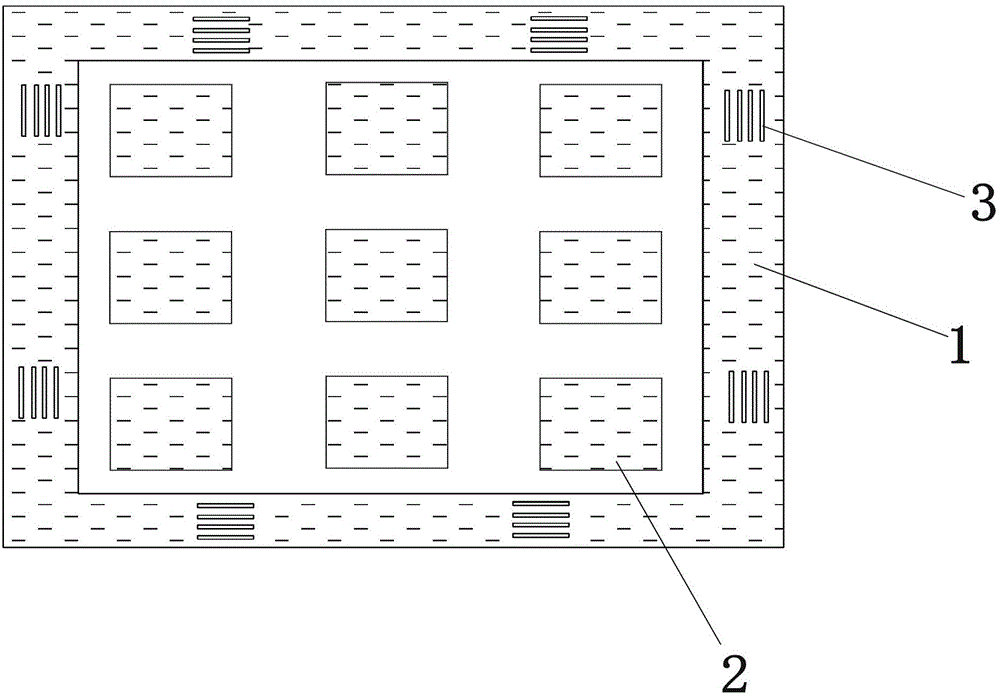

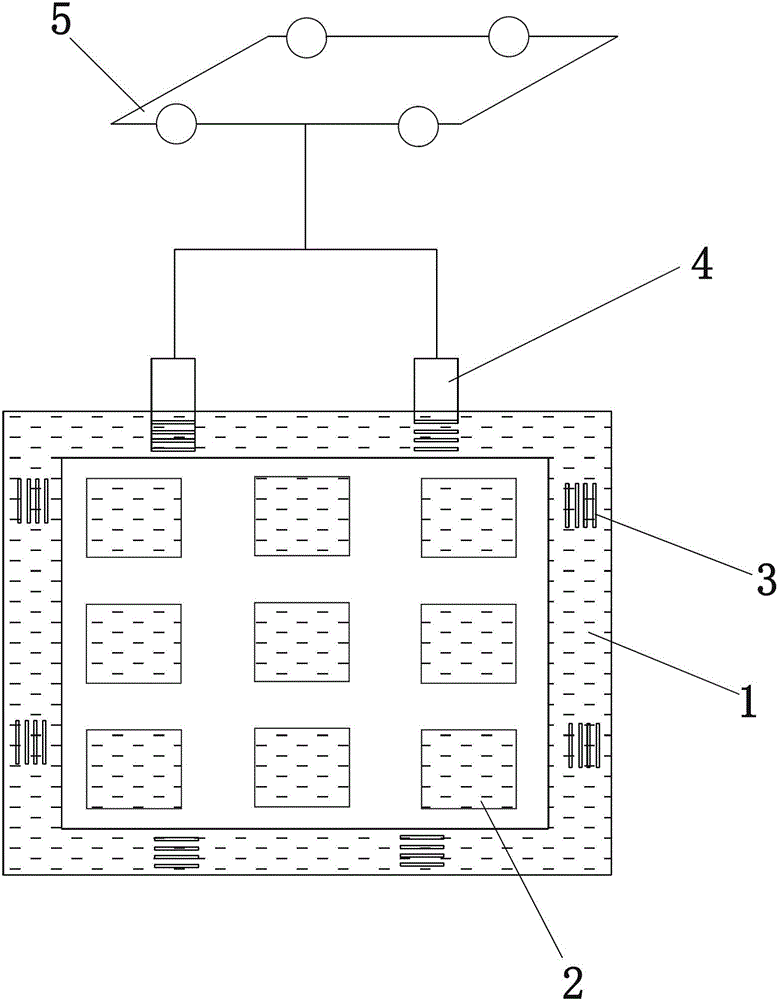

Image

Examples

Embodiment Construction

[0019] In order to illustrate the idea and purpose of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0020] The invention provides a method for making a board edge graphic tool to prevent electrostatic spraying from falling off the board, which mainly includes the following steps:

[0021] A. Cutting the copper clad laminate, forming a multi-layer circuit board after making inner graphics and pressing, drilling and electroplating, or forming a single-sided circuit board after drilling and electroplating;

[0022] The multi-layer circuit board needs to cut the copper clad laminate first, and then form the inner layer graphics and press, drill, and electroplate; the single-sided circuit board needs to cut the copper clad laminate, and then go through drilling and electroplating. After forming, whether it is a multi-layer board or a single-layer board, the copper-clad laminate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com