Fastener for attaching together workpieces having aligned holes therethrough

A technology for fasteners and alignment holes, applied to threaded fasteners, connecting components, thin plate connections, etc., which can solve the problems of high production, storage and distribution costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

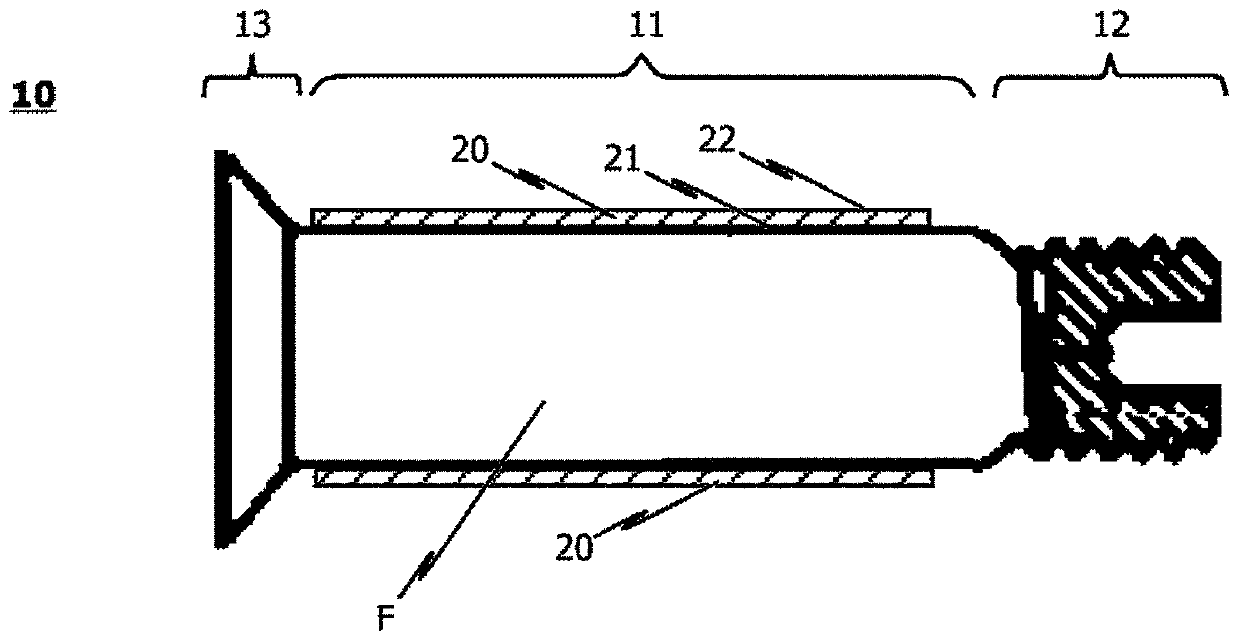

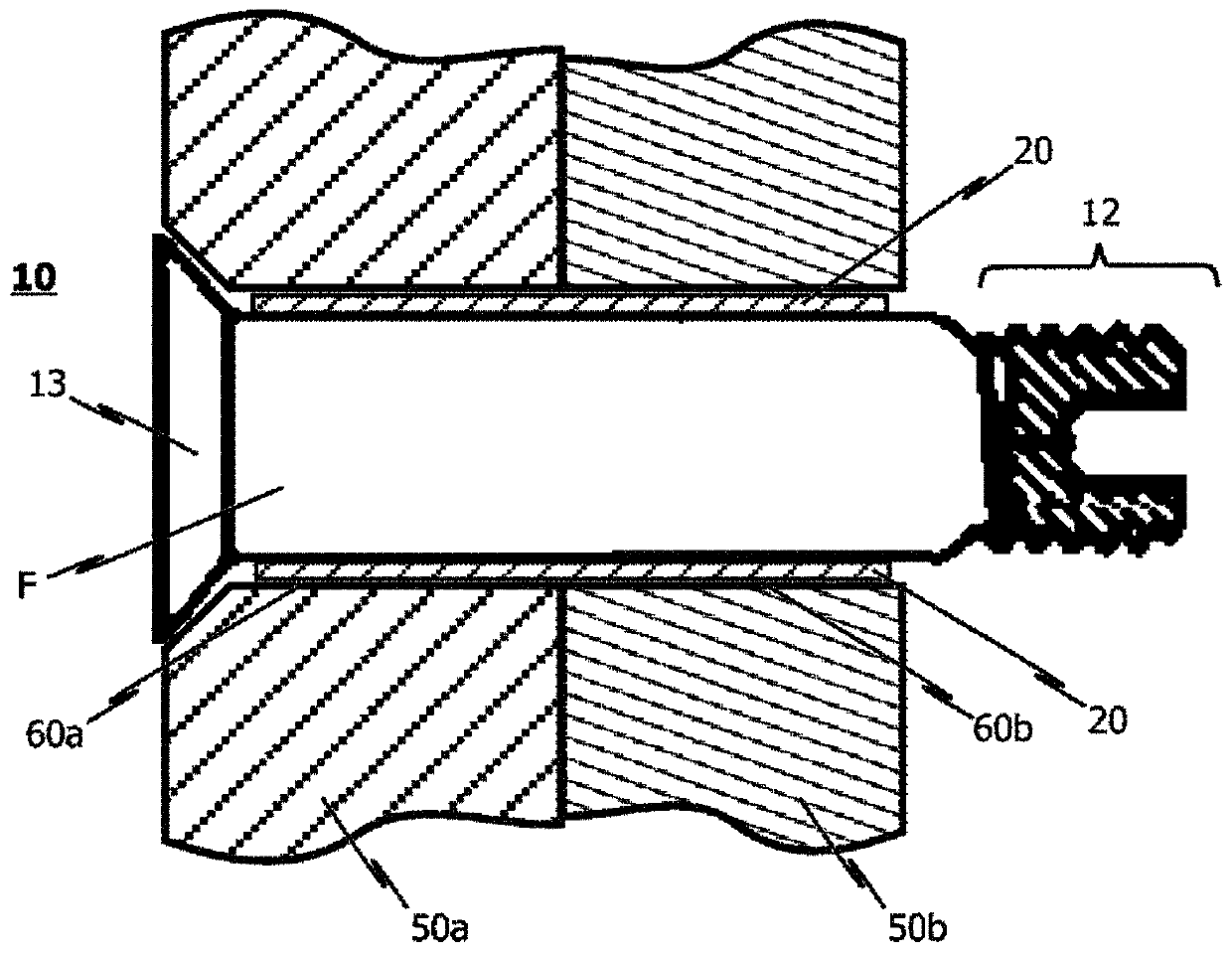

[0030] A fastener 10 is disclosed for securing a plurality of workpieces together and adapted to be positioned in aligned holes 60a, 60b in such workpieces 50a, 50b. In an exemplary embodiment, fastener 10 may include a pin or bolt member defining a shank 11 .

[0031] Although not shown in the drawings, the fastener 10 may also include a nut. In other embodiments, instead of a nut, the fastener 10 may comprise a collar, in particular a swaged collar. Additionally, the fastener 10 may also include a sleeve member (also not shown in the figures).

[0032] In an exemplary embodiment, workpieces 50a, 50b may be formed from a variety of materials including composite materials, metals, or composite / metal structures, or any combination thereof. In particular embodiments, workpieces 50a, 50b may be constructed of titanium, aluminum, graphite composites, or any combination thereof.

[0033] Specific reference figure 1, the exemplary embodiment of the invention consists of a conven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com