Cleaning device for log processing

A cleaning device and technology for logs, which are applied in the directions of cleaning methods using tools, cleaning methods using liquids, cleaning methods and utensils, etc., and can solve the problems of inconvenient log stacking, inconvenient log turnover, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

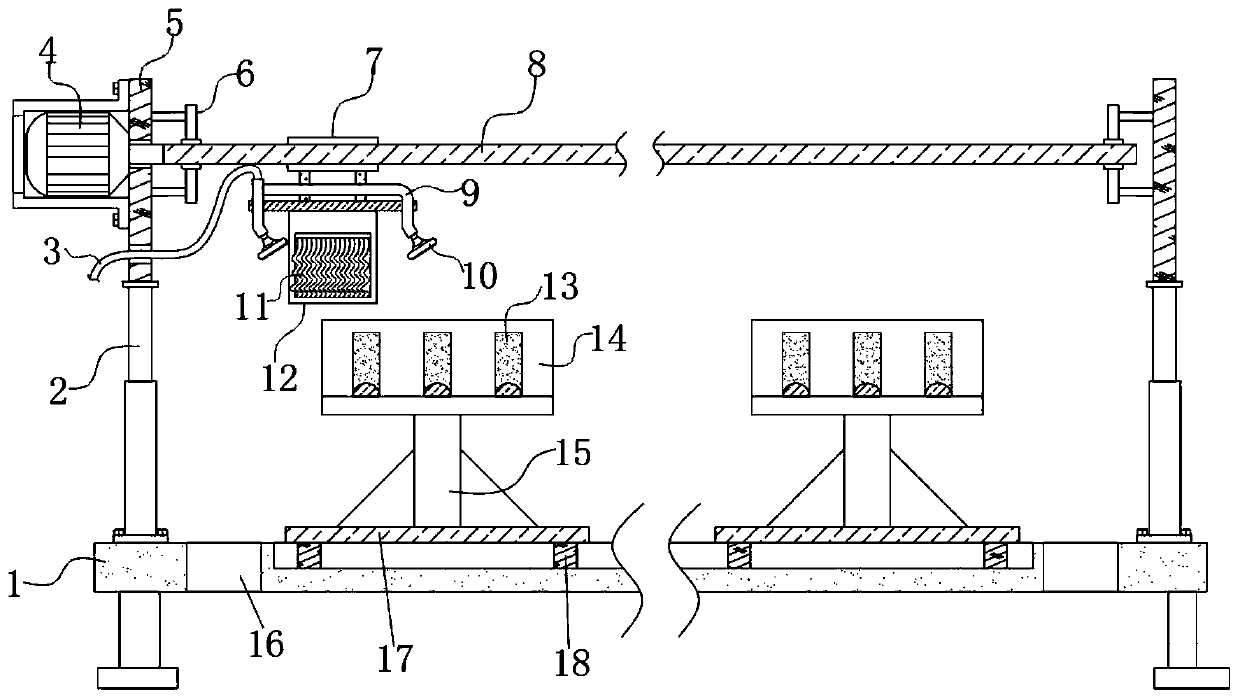

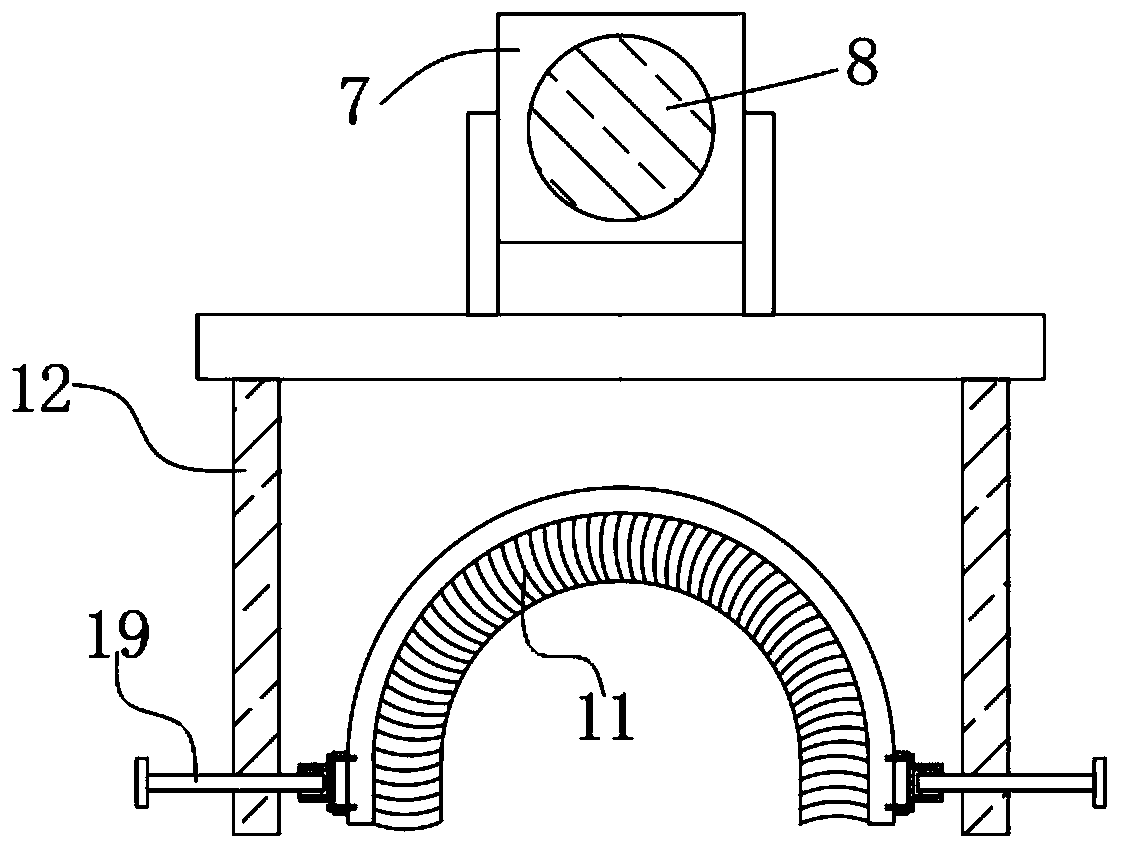

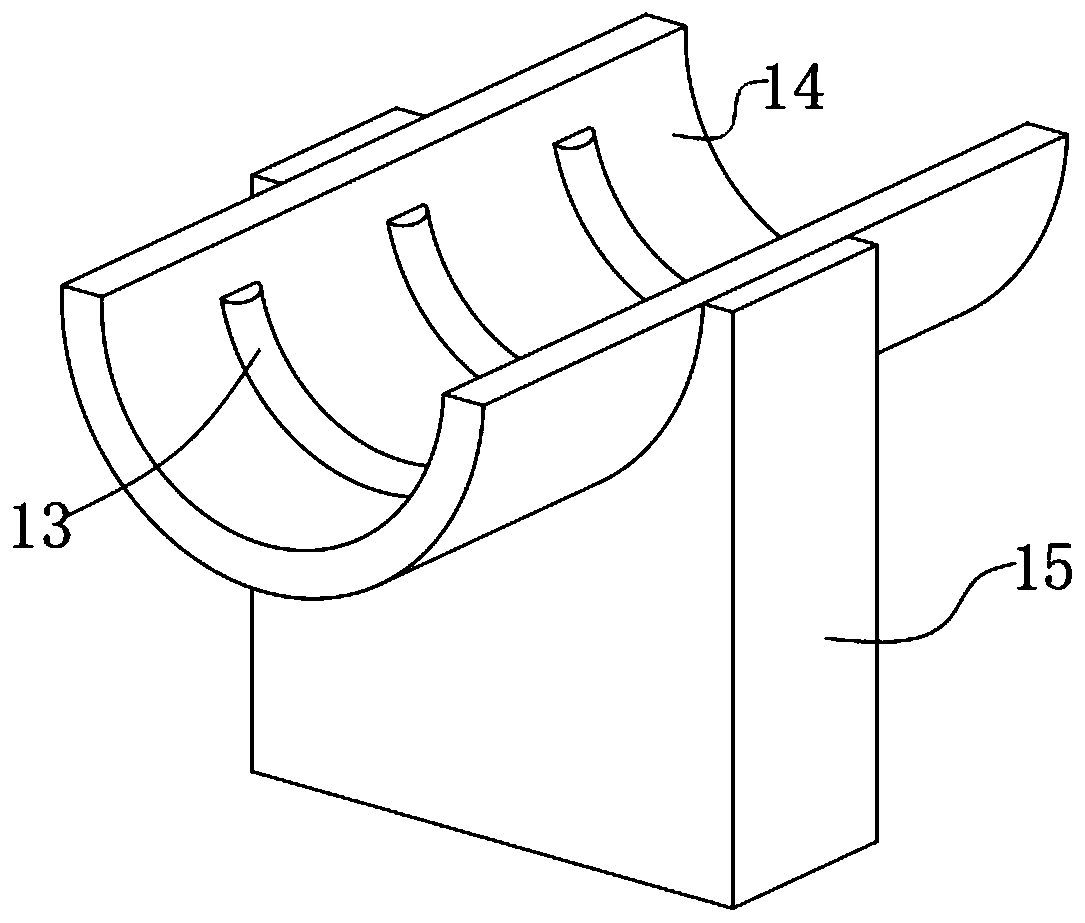

[0023] Reference Figure 1-3 , A cleaning device for log processing, including a placing table 1 and a cleaning mechanism, the top outer wall of the placing table 1 near the four corners are fixed with an electric telescopic rod 2 by bolts, and further, the electric telescopic rod 2 is connected with a wire The same switch one, the switch one is connected to an external power supply through a wire, the top ends of the two electric telescopic rods 2 on the same side are fixed with the same side plate 5 by bolts, and the outer walls of the two side plates are welded with mounting seats. 6. The top outer wall of the placing table 1 has four strip grooves, and the top outer wall of the mounting seat 6 is provided with two supporting mechanisms. The two ends of the processed log are placed on the two arc-shaped plates 14 respectively. This completes the placement of the logs. The supporting mechanism includes a backing plate 17. The bottom outer wall of the backing plate 17 is welde...

Embodiment 2

[0030] Reference Figure 4 , A cleaning device for log processing, this embodiment is compared with embodiment 1, the main difference is that in this embodiment, the bottom of the placing table 1 is welded with a topless water collection box 20, the bottom surface of the water collection box 20 is inclined, A drain hole is opened on one side of the outer wall of the water box 20 near the bottom, and the inner wall of the drain hole is welded with a drain pipe, and the drain pipe is located on the lower side near the water collection box 20.

[0031] Working principle: The waste water generated during cleaning leaks out of the four strip-shaped holes 16 into the water collecting box 20, and is discharged from the drain pipe along the inclined bottom surface of the water collecting box 20.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com