Synthesis and application of a tripod quaternary ammonium salt gelling factor and its supramolecular smart film

A technology of salt gelling factor and gelling factor, applied in the field of making smart windows, can solve the problems of inferior quality and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、 3

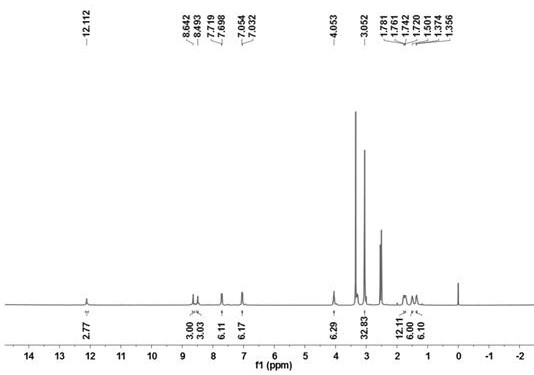

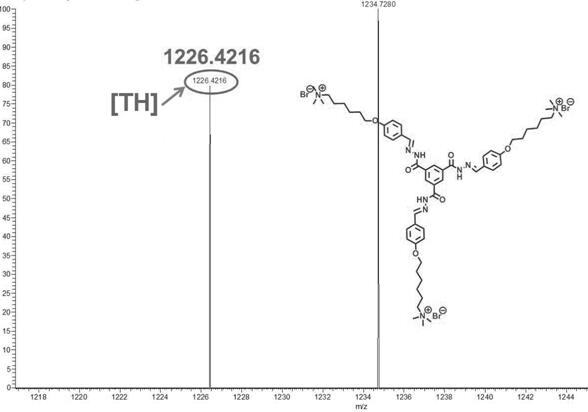

[0038] Example 1. Synthesis of Tripod Quaternary Ammonium Salt Gelling Factor (TH)

[0039] (1) Synthesis of p-hydroxybenzaldehyde functionalized quaternary ammonium salt: add 1.5 mmol (0.3629 g) 1,6-dibromohexane and 0.5 mmol KI (0.083 g) to 200 ml of acetone, stir at room temperature for 30 minutes, add 0.138g K 2 CO 3 (1 mmol) and 1 mmol p-hydroxybenzaldehyde (0.122 g) immediately with N 2Protection, the mixture was heated to reflux at 60~65 ° C for 70~72 hours, and then the silica gel was rotated and stirred, and the product was purified by column chromatography, eluted with petroleum ether: ethyl acetate = 10: 1 to obtain a white Powdered solid M 2 was 0.2840g, yield: 70.4%; then in 2ml ethyl acetate, 0.5gM was added 2 and 2ml of trimethylamine, stirred at room temperature for 20-25 minutes, concentrated, then added 5ml of acetonitrile and 1ml of water, and concentrated 3-4 times to obtain a white powdery solid, which is p-hydroxybenzaldehyde functionalized quaternary...

Embodiment 2

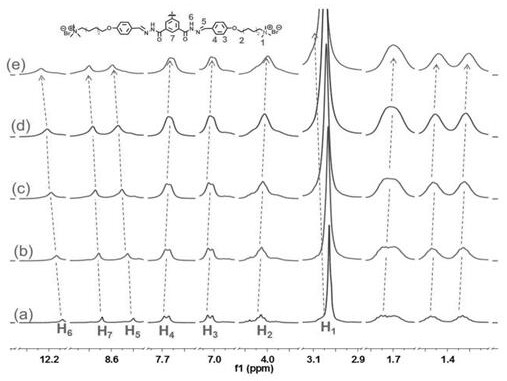

[0041] Embodiment 2, the preparation of supramolecular smart film

[0042] 0.0100 g of TH was added to 200 μL of distilled water, heated to completely dissolve TH, and then cooled at room temperature to obtain a stable supramolecular hydrogel. The supramolecular hydrogel is evenly coated on the glass substrate, and then dried to remove the water solvent, to prepare a supramolecular smart adhesive film attached to the glass substrate, and the thickness of the adhesive film is 2.5~3×10 -3 mm. The film is colorless and transparent, and its light transmittance can reach 97.1%.

[0043] Fumigating TH-GF with TEA steam, the film will turn from transparent to opaque. Then TH-GF fumigated by TEA with HCl vapor, the film will continue to transform from opaque to transparent, and can switch between transparent and opaque many times under the alternating action of TEA and HCl vapor. Therefore, the film can be used as a smart glass coating to prepare smart glass to dynamically and reve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com