An electrochemical system and a method for changing the response mode of a plasmon sensor

An electrochemical and electrode technology, applied in the field of materials, to achieve high signal contrast and achieve reversible switching effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0098] In this embodiment, a magnetic plasmon sensor is prepared.

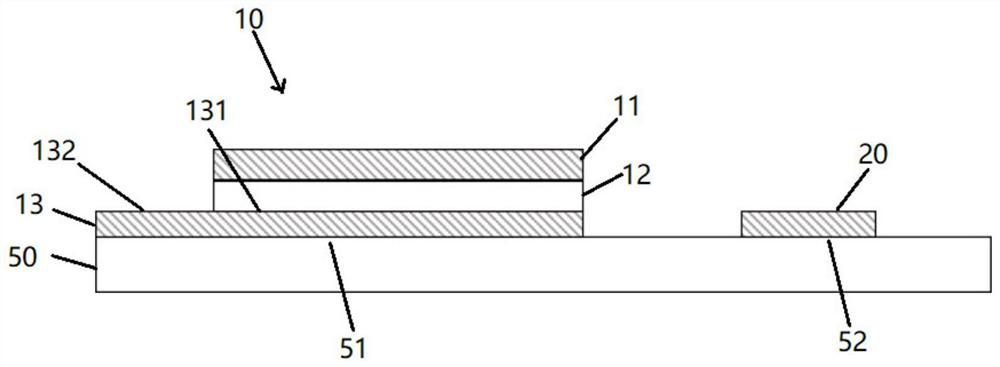

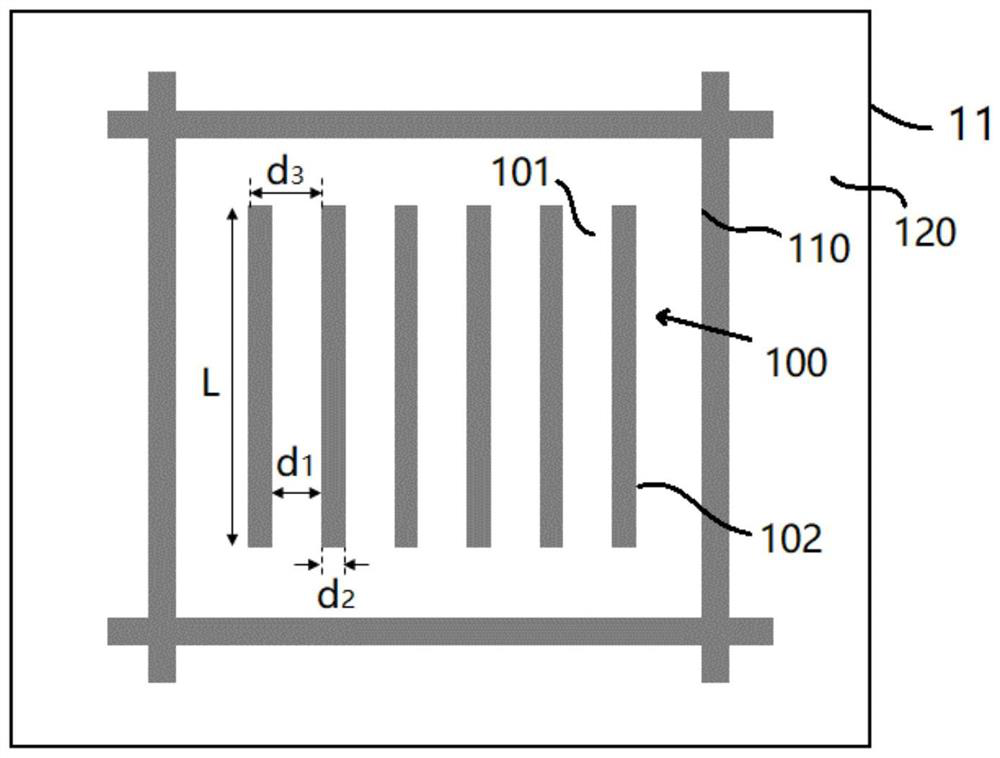

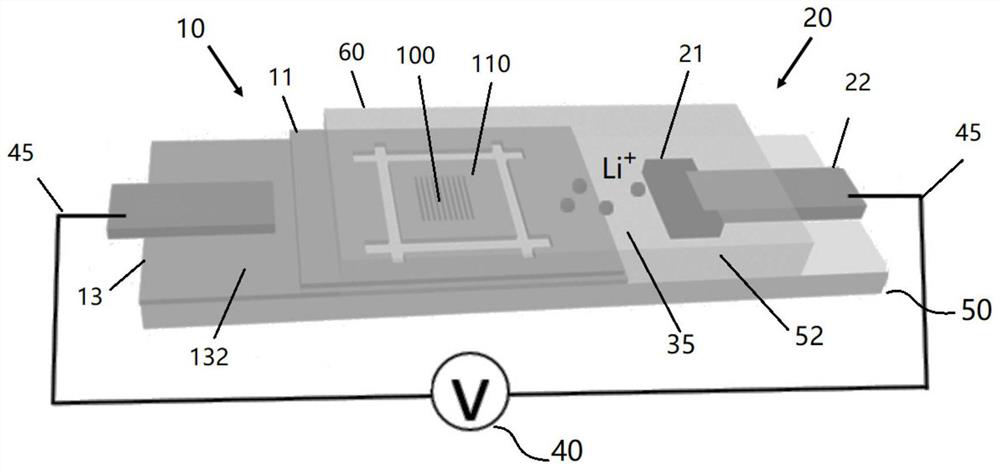

[0099] figure 1 A side view of the plasmon sensor of Example 1 is shown. figure 2 A top view of the metal upper layer of the plasmonic sensor of Example 1 is shown. image 3 An electrochemical system including the plasmonic sensor is shown.

[0100] Such as figure 1 and 2 As shown, the preparation method of the plasmonic sensor 10 is as follows:

[0101] (1) Provide a quartz plate 50 with a thickness of 1mm, divide the first area 51 and the second area 52 on the quartz plate 50, the first area 51 is used to set the plasmon sensor 10, and the second area 52 is subsequently used for configuring the second electrode when assembling the electrochemical system;

[0102] (2) Deposit a metal substrate 13 (material: Ag) with a thickness of 100 nm on the first region 51 by using a physical vapor deposition method;

[0103] (3) adopt the physical vapor deposition method, divide the 3rd region 131 and the 4th reg...

Embodiment 2

[0114] In this example, an electrochemical system containing a plasmon sensor was prepared.

[0115] image 3 A schematic diagram of the electrochemical system of Example 2 is shown.

[0116] As shown in the figure, the electrochemical system includes the component I of Embodiment 1, that is, a quartz plate 50 and a plasmon sensor 10 disposed thereon. The plasmonic sensor 10 serves here as the first electrode of the electrochemical system.

[0117] On this basis, the electrochemical system further includes a second electrode 20 . The second electrode 20 includes an active material 21 (lithium iron phosphate LiFePO 4 ), the active material 21 is disposed at the second region 52 of the quartz wafer 50 . The second electrode 20 also includes a tab 22 connected to the active material 21 .

[0118] On this basis, the electrochemical system further includes a power supply 40 and a wire 45, the third region 132 of the metal substrate 13 of the plasmon resonance sensor 10 is conn...

Embodiment 3

[0136] The difference between embodiment 3 and embodiment 2 lies in the location of the electrolyte. Figure 6 A schematic diagram of the electrochemical system of this example is shown.

[0137] In this embodiment, the opposite side of the quartz plate 50 is covered with a glass plate 60, the gaps around the glass plate 60 and the quartz plate 50 are sealed with epoxy resin, and the island-shaped region 110 and the active material 21 are sandwiched between the two. The epoxy resin seals the gaps around the glass plate 60 and the quartz plate 50 to form a cavity, and the island region 110 and the active material 21 are sealed in the cavity. The third region 132 of the upper metal layer 13 and part of the tabs 22 are not sealed in the cavity, and are subsequently used to connect to the power source 40 through the wire 45 .

[0138] A small hole is reserved for injecting electrolyte when sealing. After the epoxy resin glue is dry and stable, the sample is transferred to an ine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com