Dustproof transportation bag

A transport bag and dust-proof technology, which is applied in the field of transport packaging containers, can solve the problems of low efficiency of manual material removal, manual feeding, high cost, etc., and achieve the effect of avoiding the increase of labor costs and facilitating the loading and unloading of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the drawings.

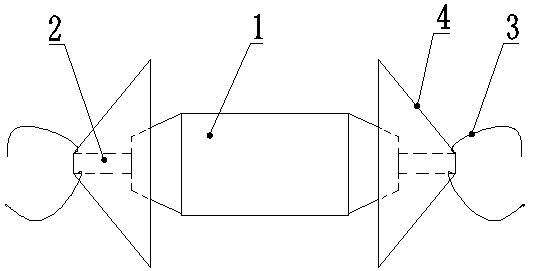

[0012] Such as figure 1 As shown, the dust-proof transport bag of the present invention includes a bag body 1. Both upper and lower ends of the bag body 1 are provided with a material port 2. The material port 2 is a flexible long cylindrical structure, and the end of the material port 2 is provided with a rope buckle. 3. A dust cover net 4 is also provided at the end of the material port 2. The manufacturer can realize loading and warehousing by matching the material outlet 2 with the raw material outlet; when the downstream manufacturer puts into production, the material inlet 2 can realize the feeding by matching with the machine inlet, which is convenient for loading and unloading materials. The end of the material opening 2 is provided with a rope buckle 3, which realizes the sealing, loading and unloading of the raw materials through the fastening and loosening of the rope buck...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com