Placing frame for die steel production

A technology for placing racks and die steel, applied in the field of placing racks, can solve the problems such as the inability to quickly and conveniently replace the drawer plate, increase the labor intensity of the operator, time-consuming and laborious disassembly, etc., so as to save manpower and material resources and reduce the time spent on disassembly. , the effect of simple structure and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

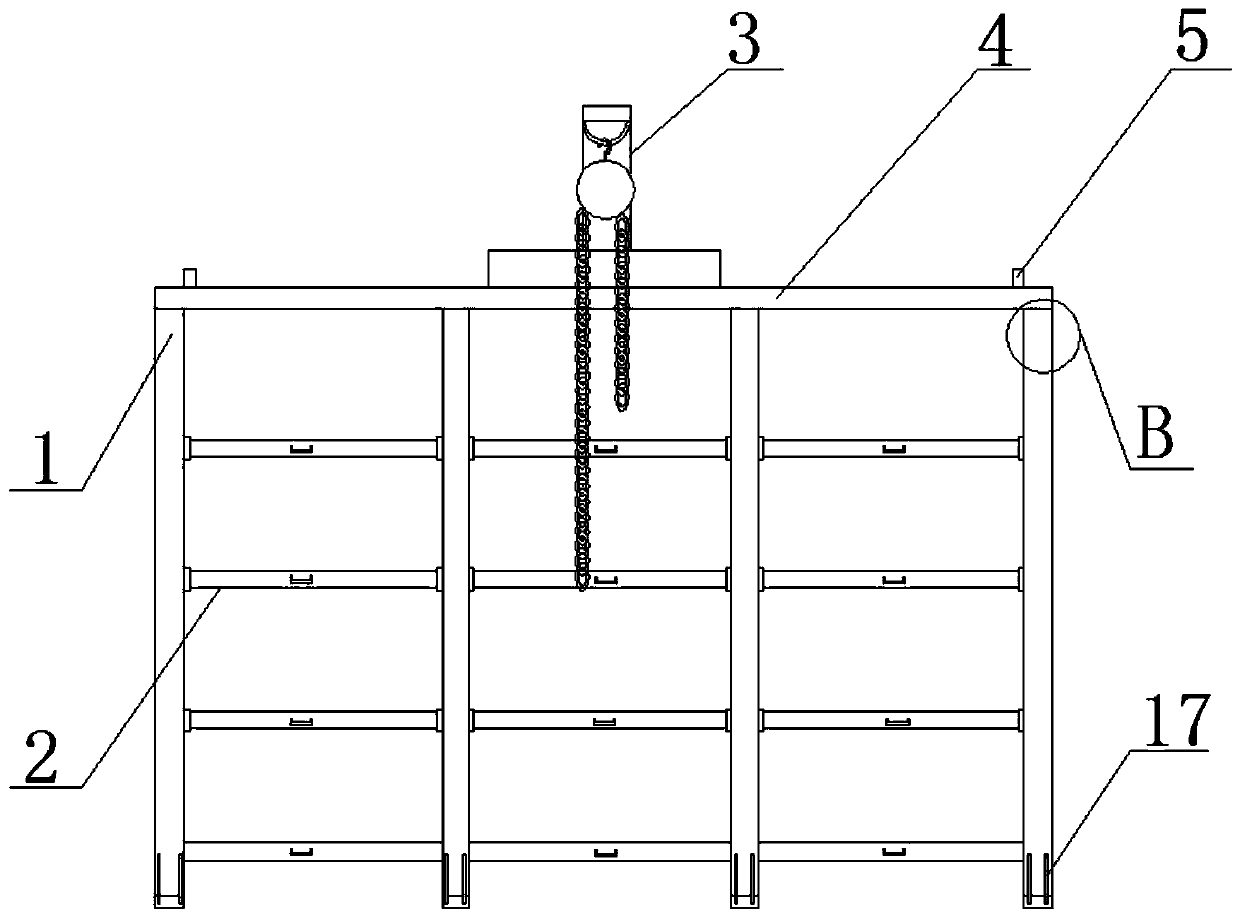

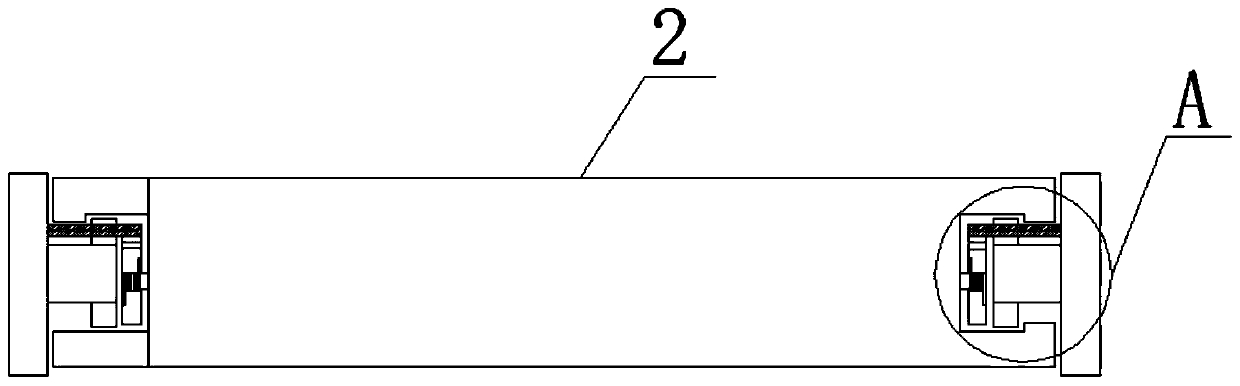

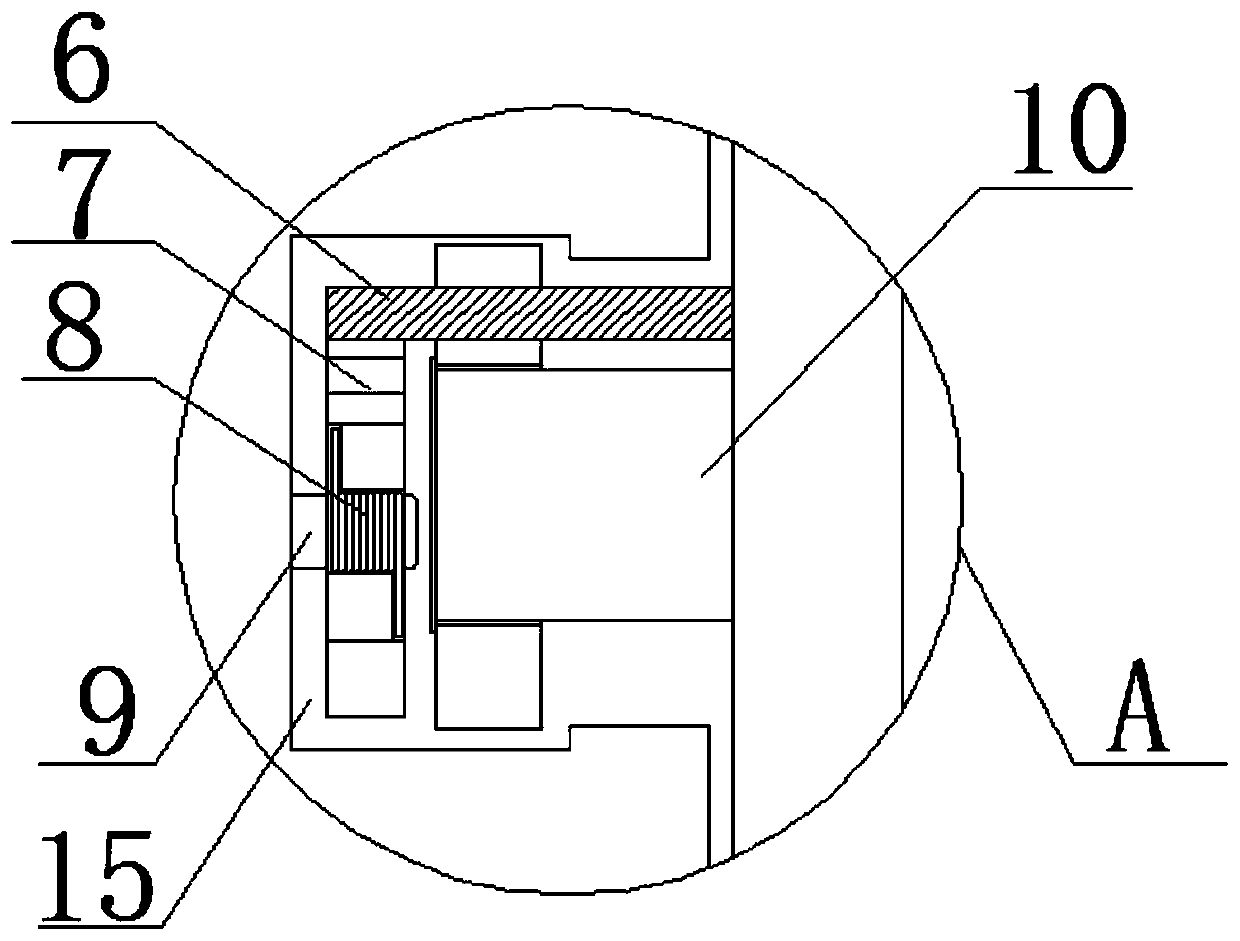

[0023] see Figure 1 to Figure 4 , the present invention provides a technical solution: a placement frame for mold steel production, including a plurality of vertical columns 1, and a plurality of pumping plates 2 are arranged equidistantly between every two columns 1, and the surfaces of the pumping plates 2 are two The side is provided with a second limit groove 15, and the two ends of the pumping plate 2 are fixed with a horizontal plate relative to the surface of the column 1. The surface of the horizontal plate is provided with a roller shaft 10, and the surface of the roller shaft 10 is provided with a roller. The retaining pile 6 is fixed on the surface, and the inner wall of the second limiting groove 15 is provided with a buckle 7 with a ">" cross-section. Through the designed buckle 7, press the upper end of the buckle 7 to bypass the retaining pile 6. The pumping plate 2 is successfully removed without turning the screw, which greatly reduces the time spent on disas...

Embodiment 2

[0025] see Figure 1 to Figure 6 , the present invention provides a technical solution: a placement frame for mold steel production, including a plurality of vertical columns 1, and a plurality of pumping plates 2 are arranged equidistantly between every two columns 1, and the surfaces of the pumping plates 2 are two The side is provided with a second limit groove 15, and the two ends of the pumping plate 2 are fixed with a horizontal plate relative to the surface of the column 1. The surface of the horizontal plate is provided with a roller shaft 10, and the surface of the roller shaft 10 is provided with a roller. The retaining pile 6 is fixed on the surface, and the inner wall of the second limiting groove 15 is provided with a buckle 7 with a ">" cross-section. Through the designed buckle 7, press the upper end of the buckle 7 to bypass the retaining pile 6. The pumping plate 2 is successfully removed without turning the screw, which greatly reduces the time spent on disas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com