Fragmentation device

A component, conveyor technology, applied in the field of glass breaking devices, capable of solving problems such as unsatisfactory, high resistance of window frames, not allowing broken components premature wear contingency plan, etc., to achieve the effect of reducing stress load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

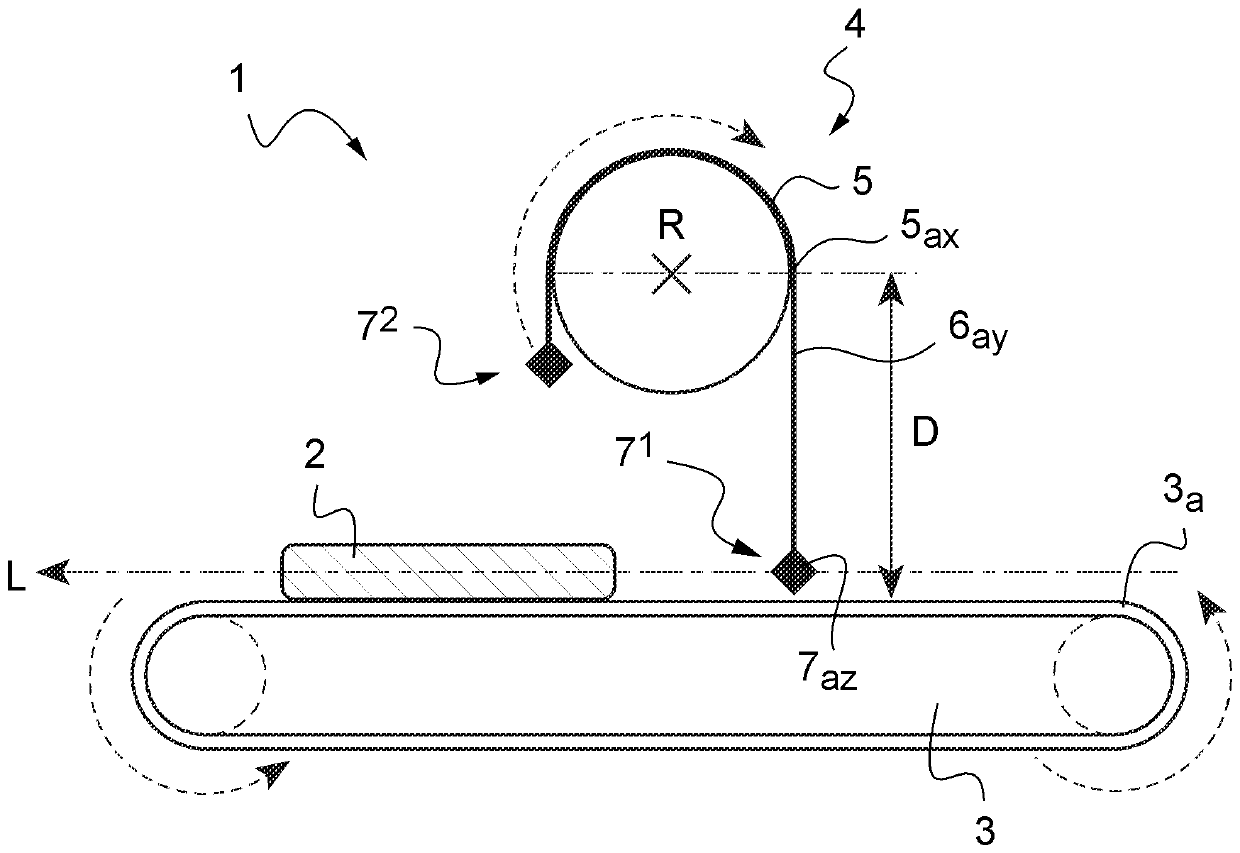

[0054] Such as figure 2 As shown, a breaking device 1 according to a particular embodiment of the invention is designed to break the glass of a used window 2 and comprises:

[0055] - a conveyor 3 designed to convey said window 2 flatly along the longitudinal axis L, and

[0056] - Fragmentation assembly 4, which is located above the conveyor 3 and is designed to fragment the glass of the window 2 as it is conveyed on the conveyor 3.

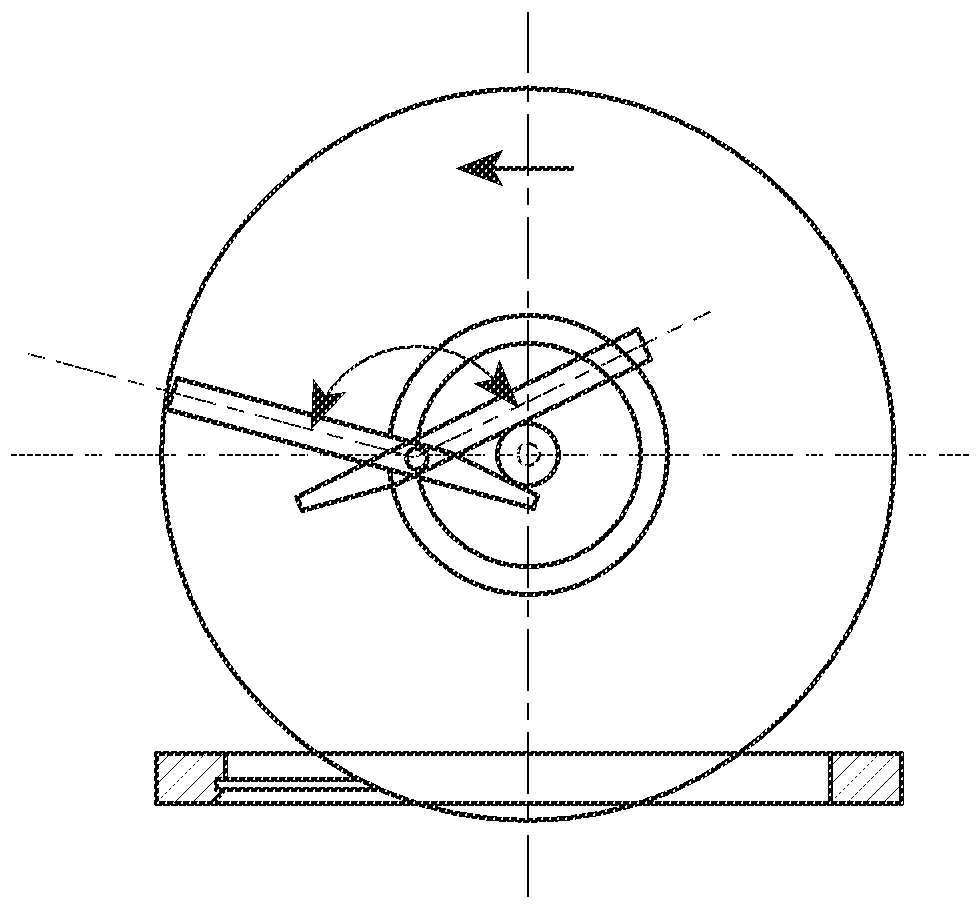

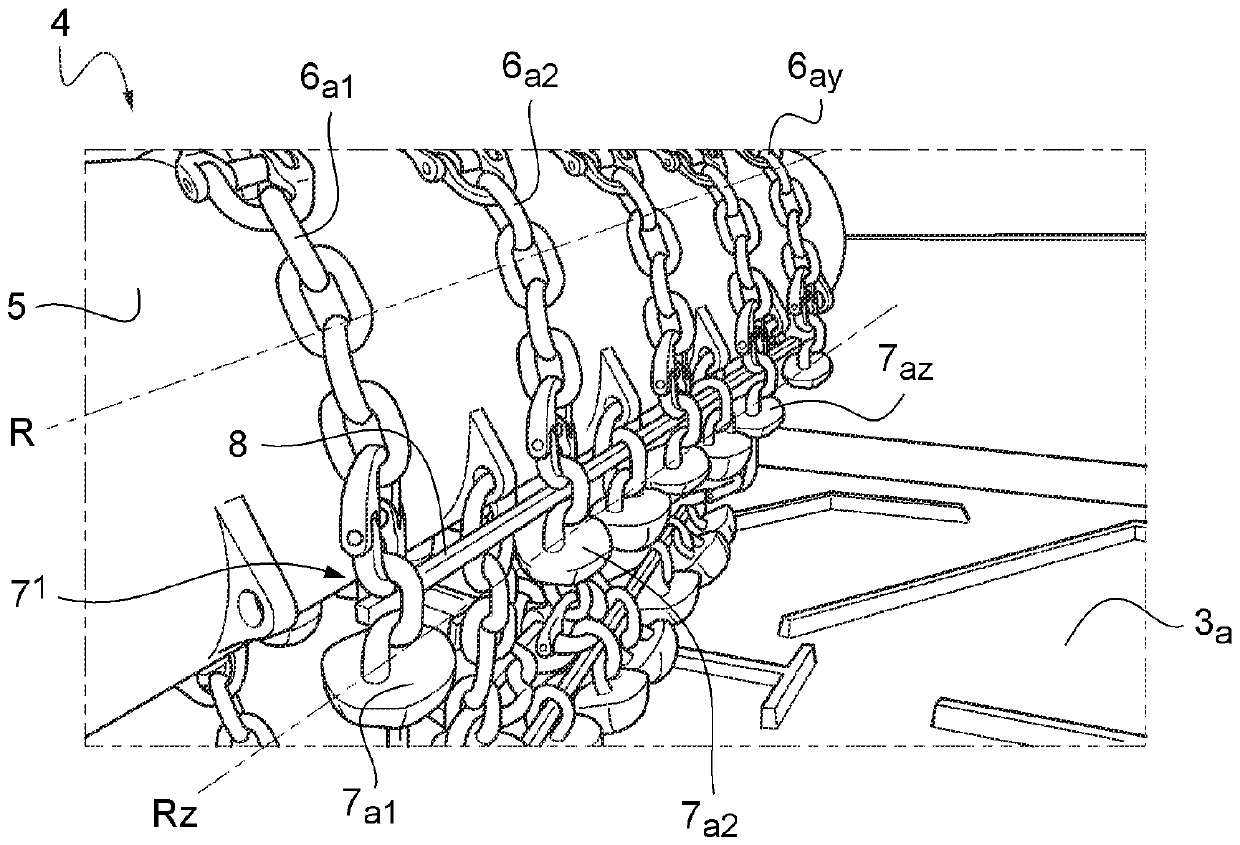

[0057] More specifically, the fragmentation assembly 4 comprises a roller 5 arranged above the conveyor 3 along an axis of rotation R transverse to the longitudinal axis L.

[0058] The drum 5 is connected to the two striker assemblies (7 1 、7 2 ), each impactor assembly 7 1 Consists of a plurality of impact heads (7a1, 7a2, . . . , 7az) designed to impact the conveyor 3 each time the drum 5 rotates.

[0059] For each striker assembly 7 , strike heads ( 7a1 , 7a2 , . . . , 7az ) are aligned in the transverse direction Rz. So, for clarity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com