Installation and fixing method of a glass kettle and its handle

A kettle and glass technology, which is applied to water boiling utensils, kitchen utensils, household utensils, etc., can solve the problems of many materials, inconvenient use, inconvenient drilling of glass materials, fixed installation, etc., to ensure long-term use and installation process Simple, good heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

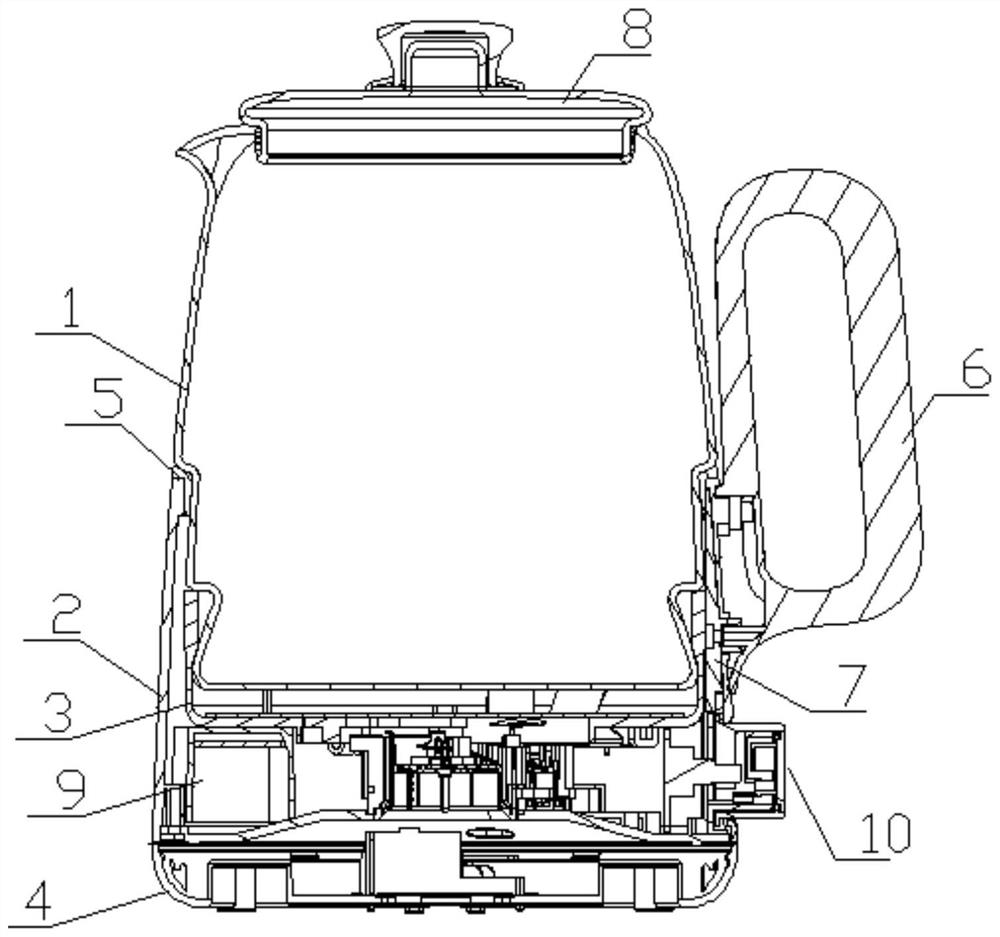

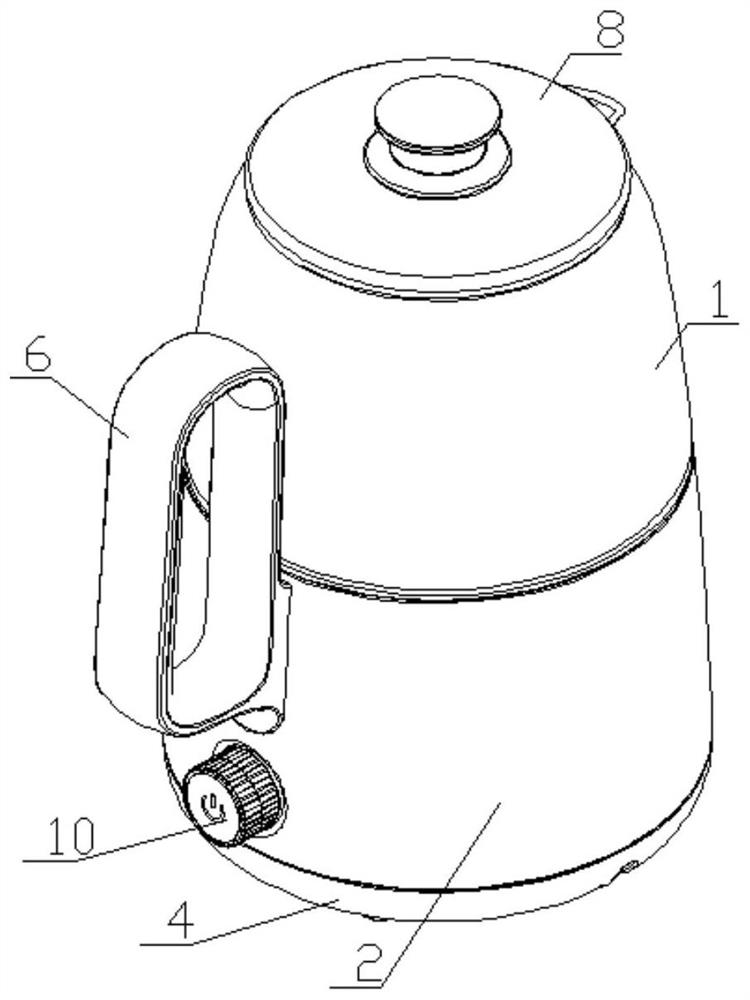

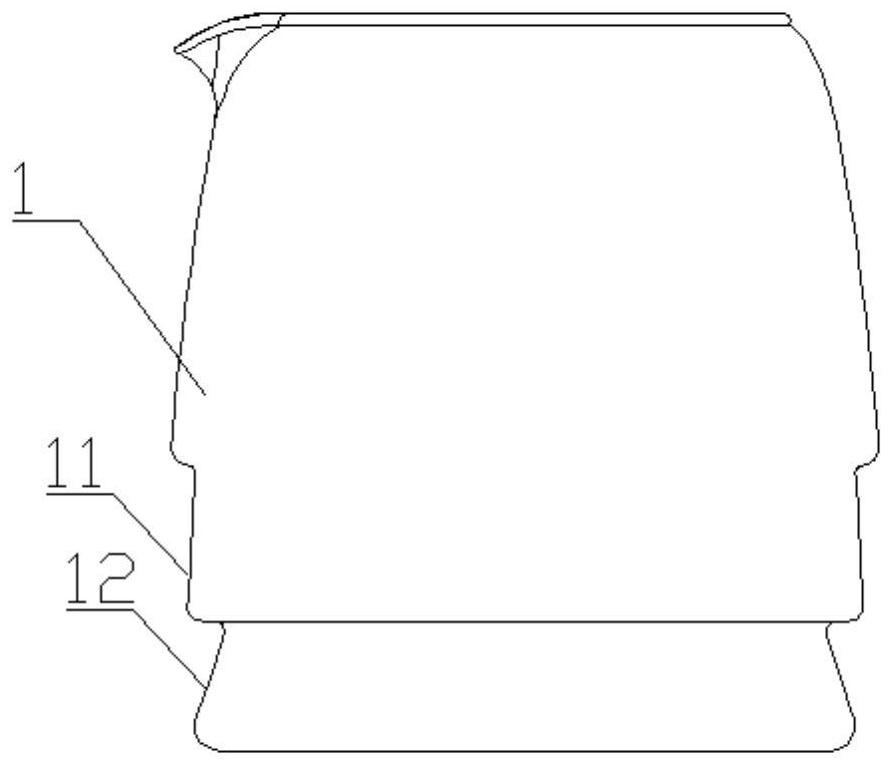

[0026] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0027] The kettle body 1 of the graphene kettle of the present invention is all glass, easy to clean, and the glass material is heat-resistant borosilicate, preferably transparent glass. Such as Figure 13 and Figure 14 As shown, the present invention can coat graphene composite heating layer 13 at the bottom of kettle body 1, graphene composite heating layer 13 is used as heating body, and graphene composite heating layer 13 both sides are provided with electrodes 14, under the condition of electrification to electrode 14 both sides The graphene composite heating layer 13 between the two electrodes 14 emits far-infrared rays, directly heating the water in the kettle rapidly. In the process of boiling water, the water only contacts with the glass pot body 1, and does not need to contact with the graphene composite heating layer 13, and no m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com