Manufacturing method of sand shooting plate and fine sand core

A manufacturing method and technology of sand shooting boards, which are applied in the manufacture of small sand cores, sand shooting boards and small sand cores, can solve the problems of affecting flow rate, flat deformation of copper pipe bends, oil circuit blockage, etc., and achieve increased Reflection strength, good technical effect, and the effect of solving bad molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

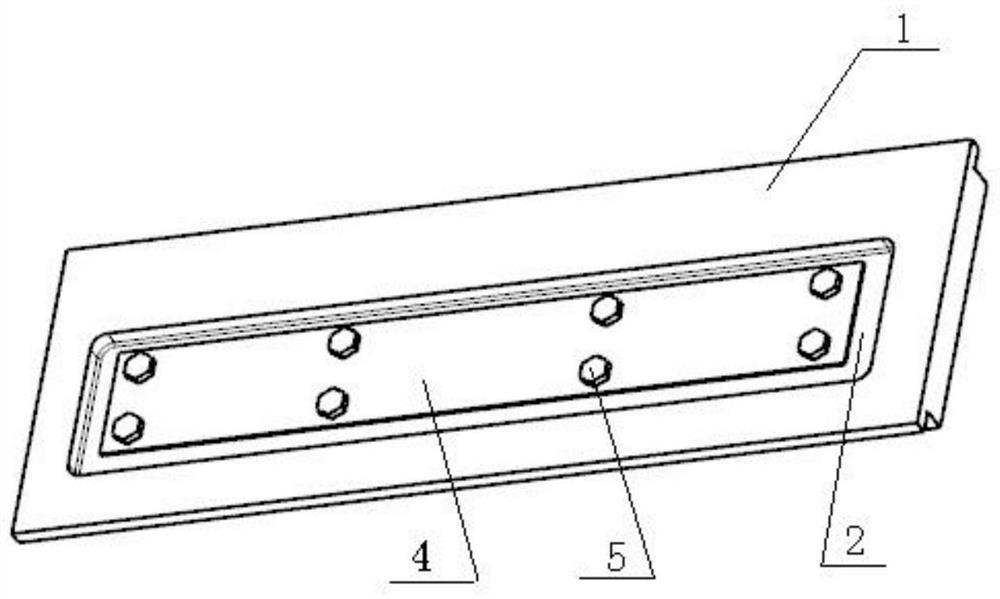

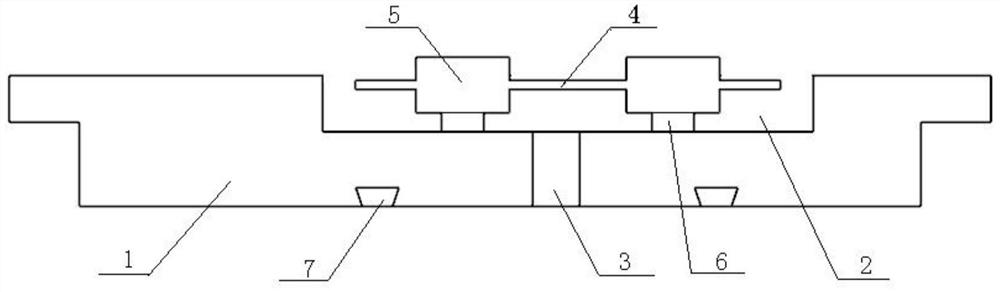

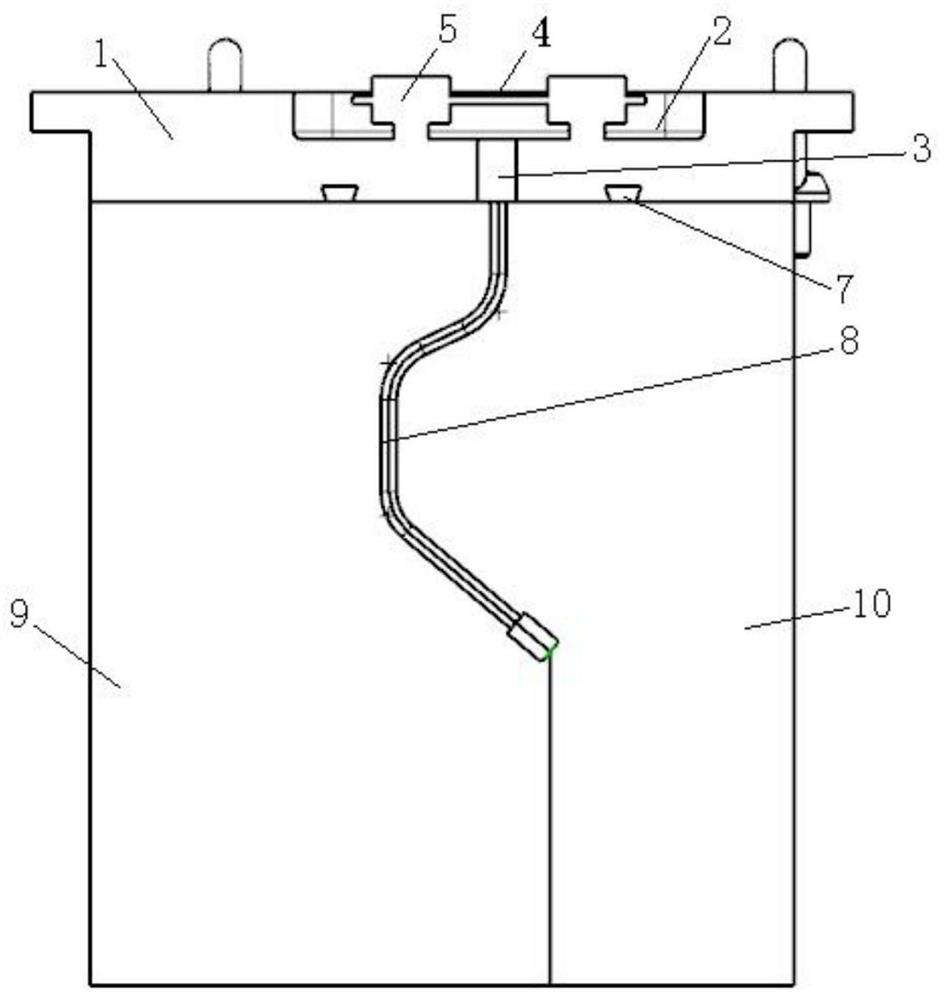

[0040]First, install the sand core mold on the core shooter, install the special sand shooting plate on the core shooter; turn on the power, and use the heating rod to preheat the mold. The mold preheating temperature is controlled at 180°C; the mold is opened to check the mold cavity, and the mold is closed after confirming that there is no foreign matter remaining in the mold cavity and no bump damage; the sand core blowing pressure is adjusted to 0.6MPa, and the sand core hardening time is adjusted to 2.5min; Then align the sand shooting hole of the special sand shooting plate with the mouth of the mold and blow the sand core; after the sand core blowing is completed, wait for the crust of the sand core to harden; On the movable half-mold, the sand core is ejected by the movable half-mold ejection system; after the sand core is taken out of the mold, it is gently placed on the tabletop in the tray with asbestos cloth in order; after the temperature drops, the sand core is cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com