A high-strength engineering steel plate with a length ≥ 30m and its production method

A steel plate and high-strength technology, which is applied to high-strength engineering steel plates and production fields, can solve problems such as increasing production costs, and achieve the effects of reducing production costs, reducing additions, and expanding application fields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is described in detail below:

[0033] Table 1 is the value list of each embodiment of the present invention and composition comparative ratio;

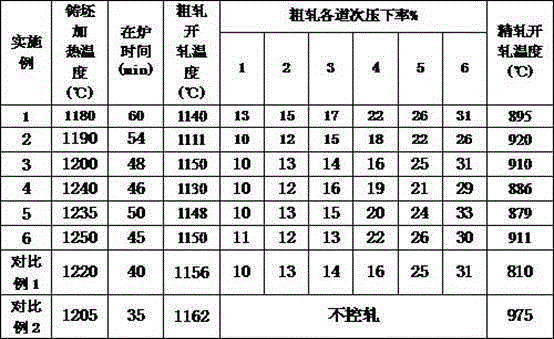

[0034] Table 2 is the main process parameter list of each embodiment of the present invention and comparative example;

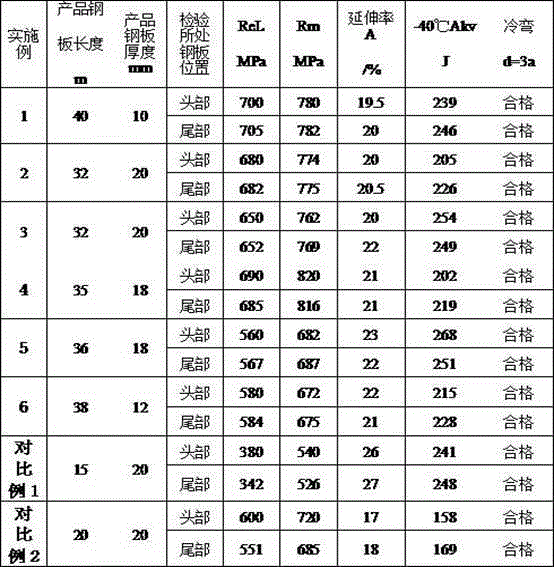

[0035] Table 3 is a list of performance monitoring conditions of each embodiment of the present invention and comparative examples.

[0036] Each embodiment of the present invention is produced according to the following steps:

[0037] 1) Smelting and continuous casting into billets;

[0038] 2) Heating the slab, controlling the soaking temperature at 1160-1250°C, and the soaking time not less than 45 minutes;

[0039] 3) Rolling using TMCP process: control the rough rolling start temperature not lower than 1100°C, and use the middle plate with a thickness that is first widened and then longitudinally rolled to 2 to 3 times the thickness of the finished product, and control the redu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com