Method for manufacturing small-core sand core

A sand core and core head technology, applied in the field of making small core head sand cores, can solve the problems of unguaranteed sand core shape and strength, difficulty in filling sand, lack of meat in the sand core, etc. Good, eliminate the dead corners of sand filling and solve the effect of sand removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

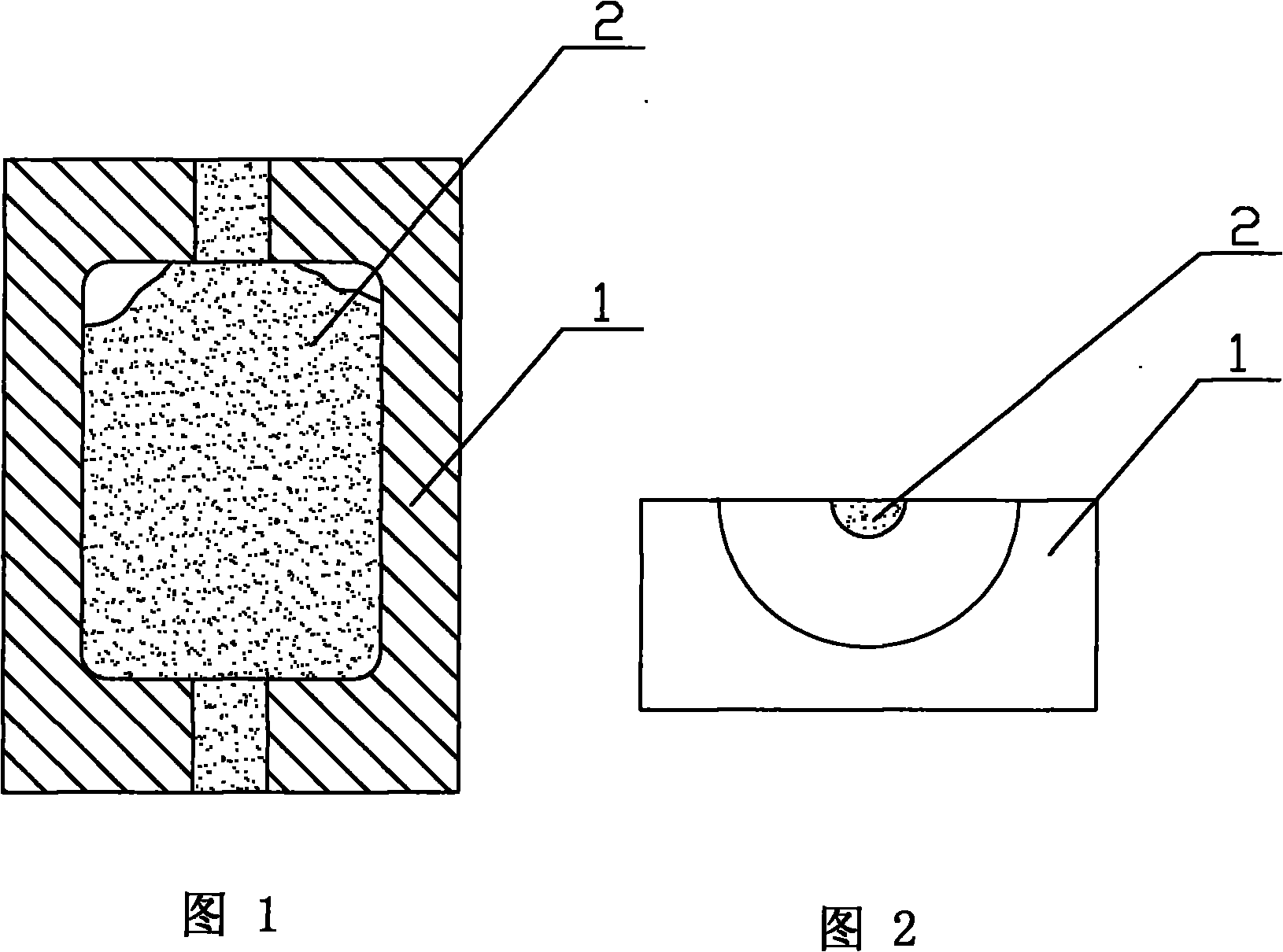

[0011] figure 1 Shown is the product obtained by the existing method of making small-core sand cores. It is not easy to fill the sanding mouth of the small-core core box with sand to fill the large internal space with sand, and the produced sand cores often have a lack of flesh, which makes The shape and strength of the sand core are not guaranteed.

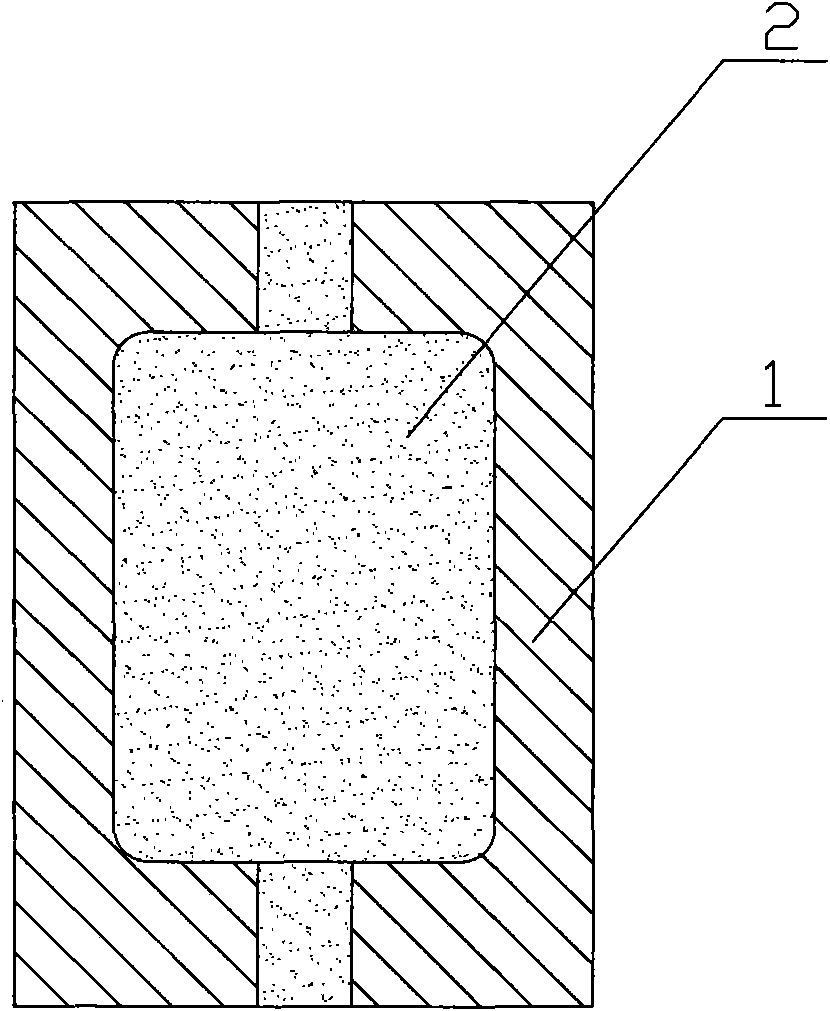

[0012] The method for making small core head sand cores in the present invention comprises the following steps: using two core boxes 1 to fill sand respectively, pounding the sand and scraping the sand to make two half cores 2; finally assembling the two half cores 2 into a complete sand core. figure 2 In order to use the present invention to make a schematic diagram of a half-core, another half-core can be made in the split core box by the same method, and the two half-cores are assembled i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com