A highly automated garment production line

A production line and ready-to-wear technology, applied in the field of garment processing, can solve the problems of complicated mechanism setting, blocked goods, shortage of goods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings so that those embodiments can be easily realized by those having ordinary skill in the art to which the present invention pertains. However, the present invention can also be realized in various forms, so the present invention is not limited to the embodiments described hereinafter. In addition, in order to describe the present invention more clearly, parts not connected with the present invention will be omitted from the drawings.

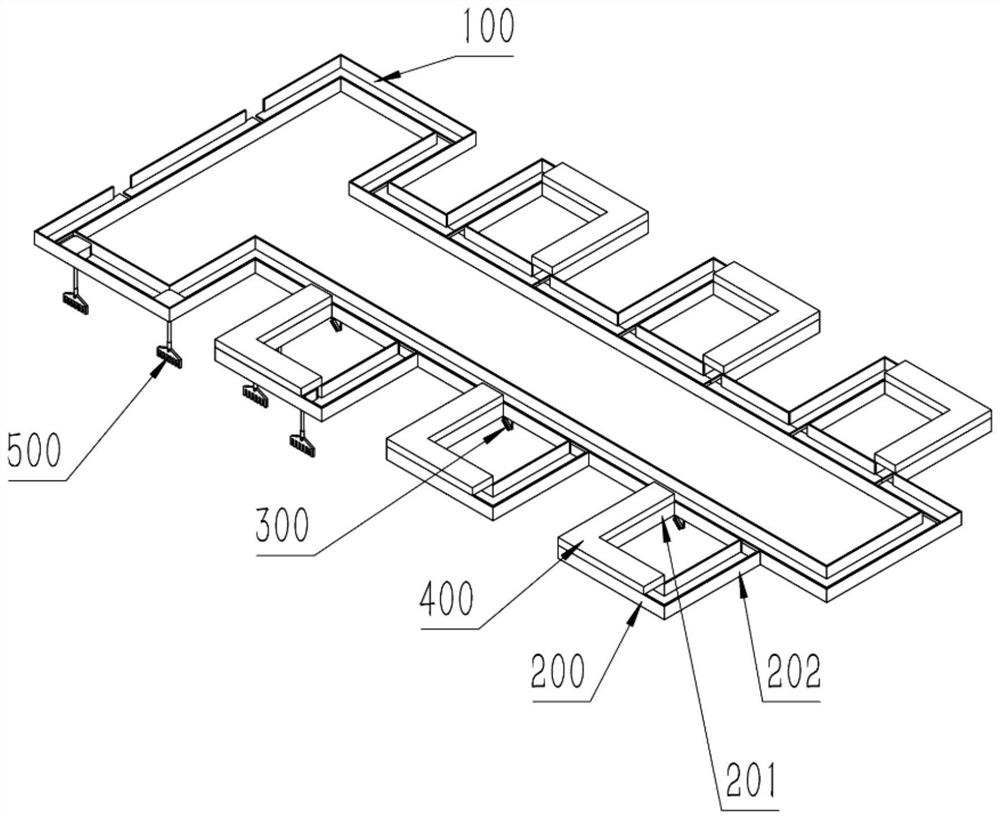

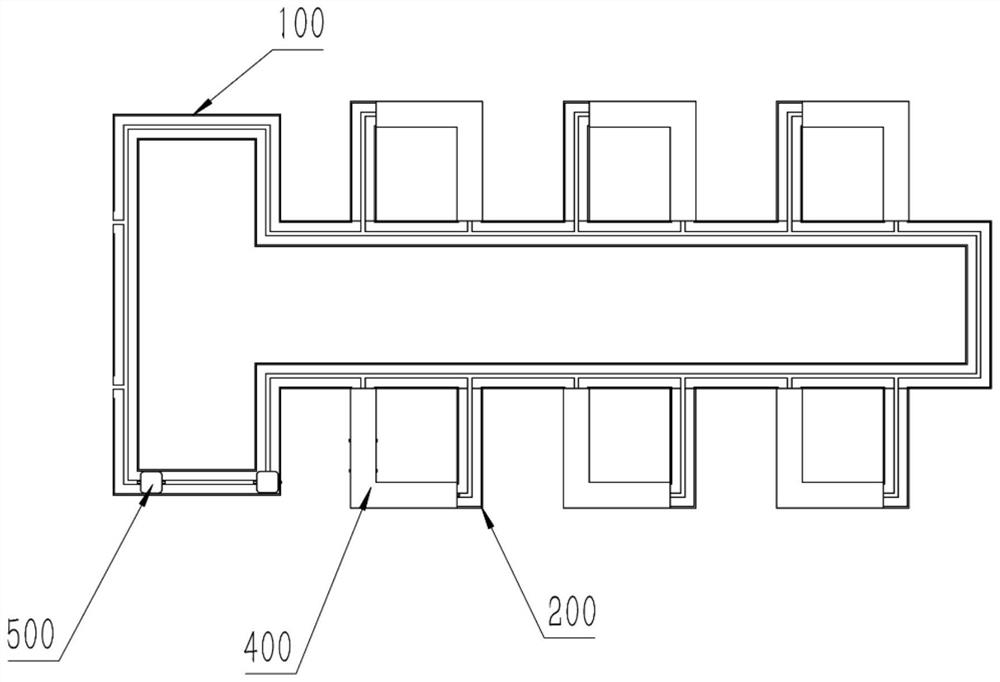

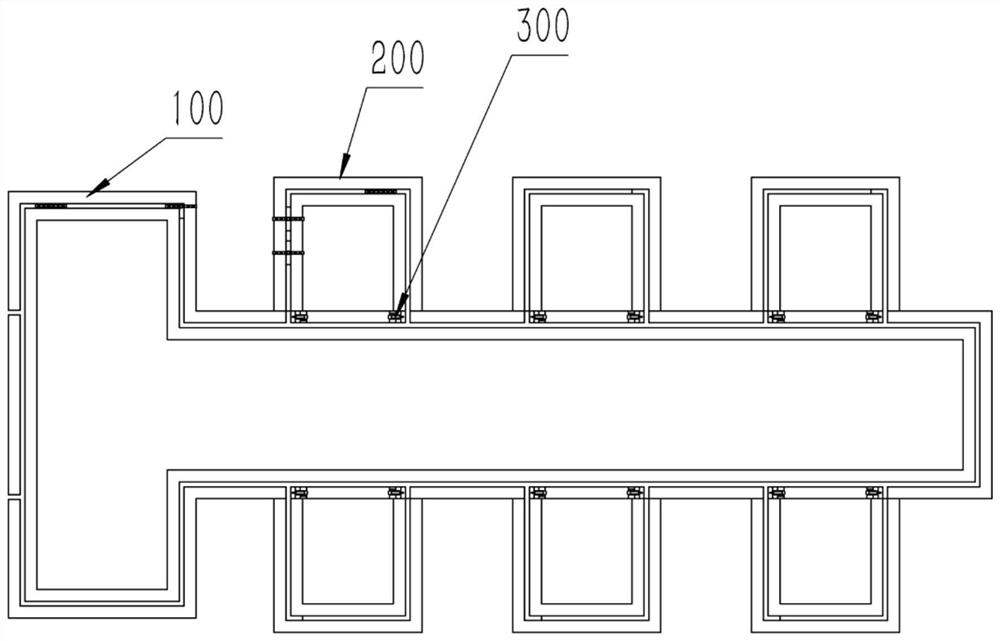

[0022] Such as Figure 1-Figure 8 As shown, a highly automated garment production line includes: a main track 100, a workstation track 200, a track connection device 300, a charging module 400, and a self-propelled clothes hanger 500;

[0023] Such as Figure 1-Figure 4 As shown, the main rail 100 is composed of two convex ring rails with L-shaped cross-sections facing each other to form a U-shaped ring rail with a U-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com