Vibratory meter with pointed flow tube

A technology for vibrating meters and flow tubes, which can be used in direct mass flow meters, volume metering, mass flow measuring devices, etc., and can solve problems such as reducing the cross-sectional area of flow tubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

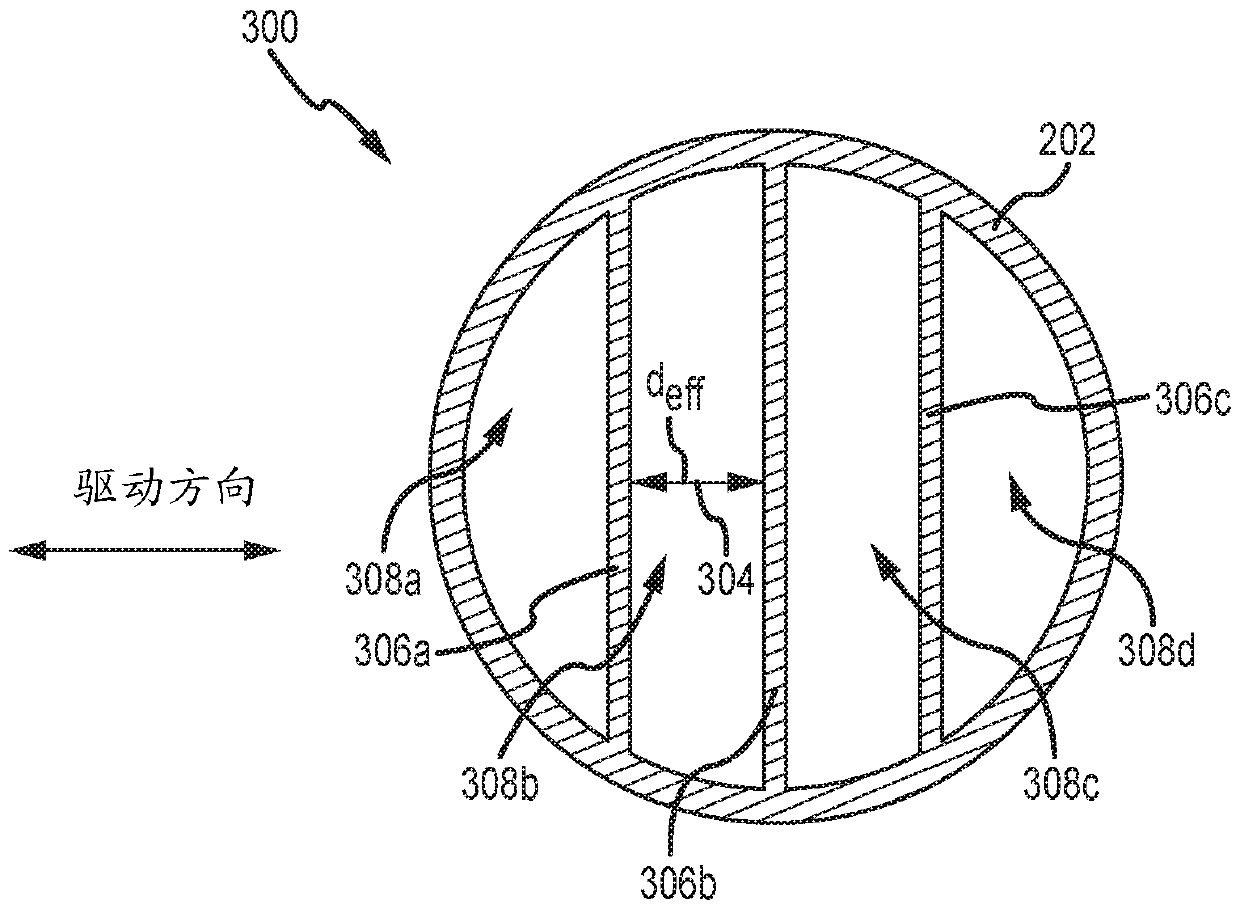

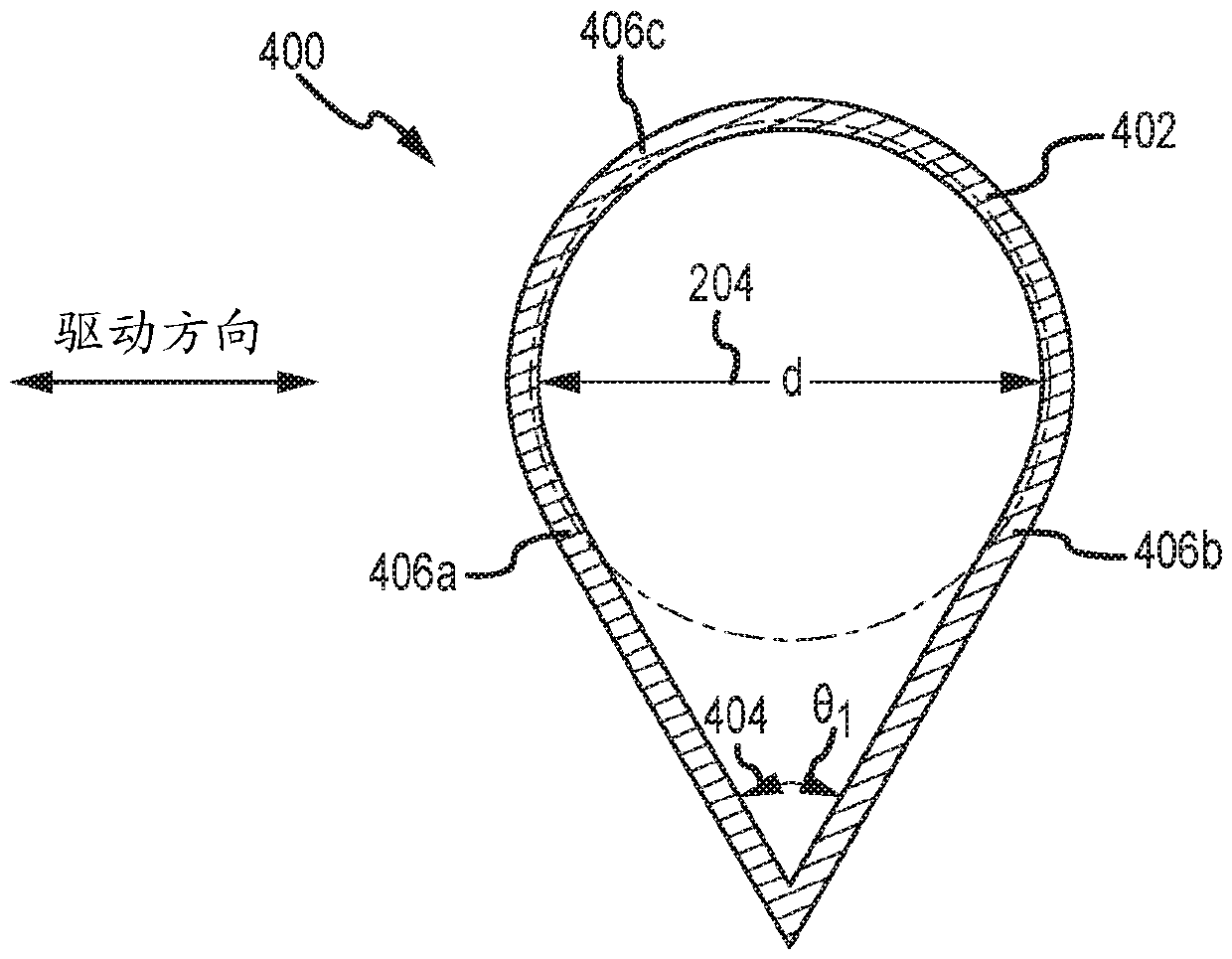

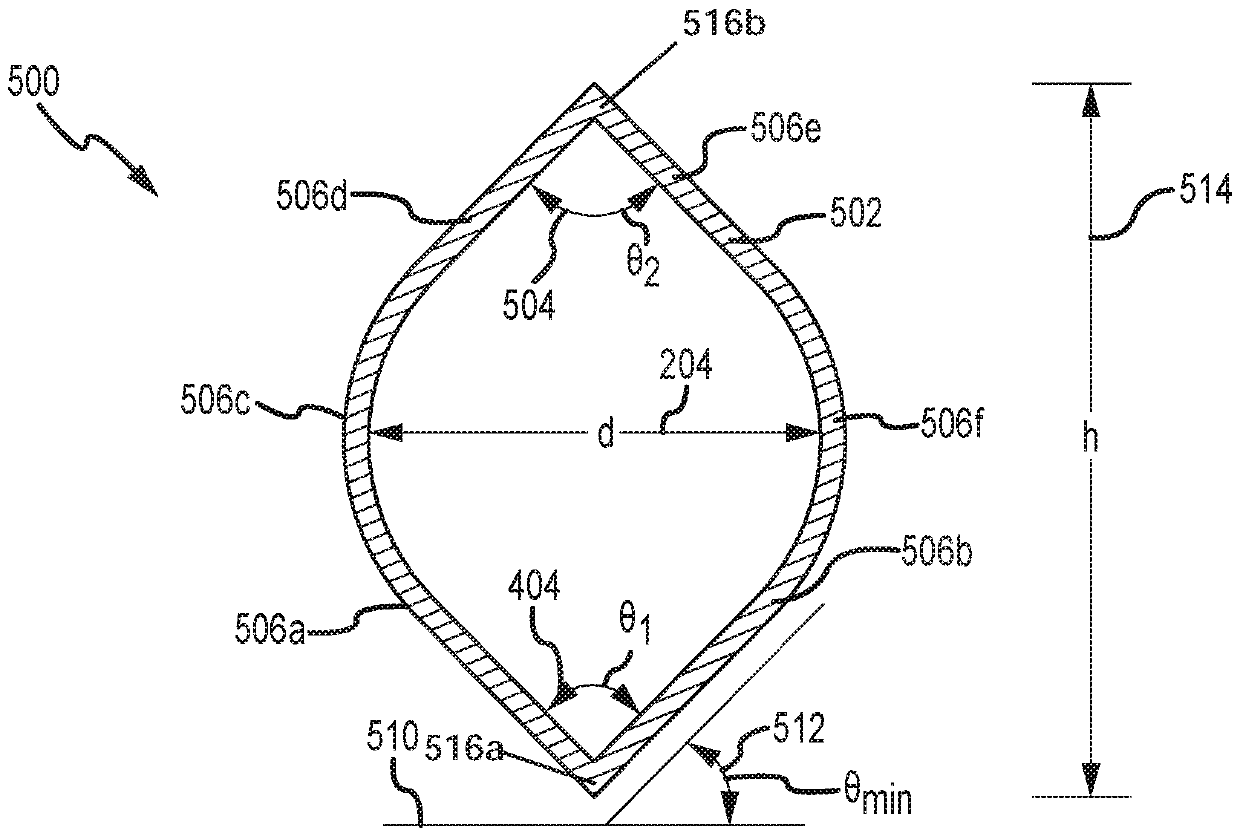

[0056] The present disclosure describes a vibrating meter including a flow tube having a pointed section and a method of forming a vibrating meter including a flow tube having a pointed section.

[0057] figure 1 A vibrating meter 5 with a multi-channel flow tube 130 according to an example is depicted. Such as figure 1 As shown in the figure, the vibrating meter 5 includes a meter assembly 10 and meter electronics 20. The meter assembly 10 is responsive to the mass flow rate and density of the process material. The meter electronics 20 is connected to the meter assembly 10 via leads 100 to provide density, mass flow rate and temperature information and other information through the communication path 26. Information and commands may also be received at the meter electronics 20 via the communication path 26.

[0058] The Coriolis flowmeter structure is described, but this is not intended to be limiting. The skilled person will easily understand that this application can be pra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com