A mounting fixture for an oil control valve

An oil control valve and installation fixture technology, which is used in the control of lubricant pressure, engine lubrication, mechanical equipment, etc., can solve the problem of technical equipment that does not specifically involve the installation of oil control valves, bolts that cannot fit the installation surface, and cannot be used once. It can be installed in place and other problems, so as to achieve the effect of convenient assembly positioning and disassembly, reducing the risk of oil leakage and reliable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

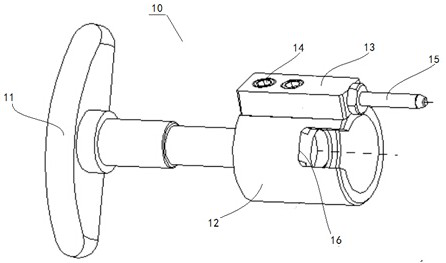

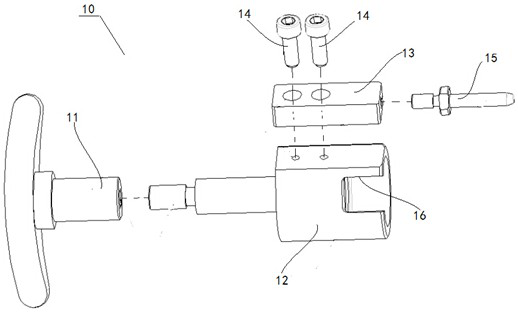

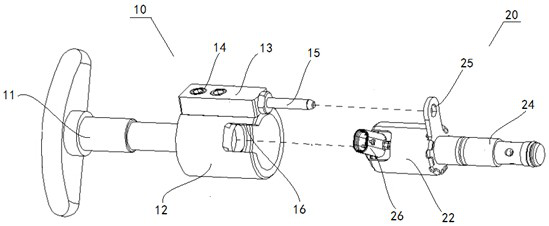

[0023] see figure 1 with figure 2 The shown installation fixture for the oil control valve includes a fixture body 10, which is characterized in that: the fixture body 10 includes a T-shaped handle 11, a guide sleeve 12 whose left end is matched with the T-shaped handle 11, and a positioning connection The guide pin positioning block 13 on the outer surface of the guide sleeve 12, the right end of the guide pin positioning block 13 is flush with the right end of the guide sleeve 12; it also includes a guide pin 15 vertically connected to the right end of the guide pin positioning block 13; An escape notch 16 is defined at the right end of the guide sleeve 12 .

[0024] The T-shaped handle is designed with reference to the function of the human hand to facilitate the movement of the oil control valve. An escape gap is opened at the right end of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com