One-way ceramic matrix composite creep behavior prediction method

A technology of composite materials and prediction methods, which is applied in the fields of analytical materials, computer materials science, measuring devices, etc., can solve the problems of high cost and time-consuming experimental methods, and achieve the effect of overcoming high cost and simple and efficient process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

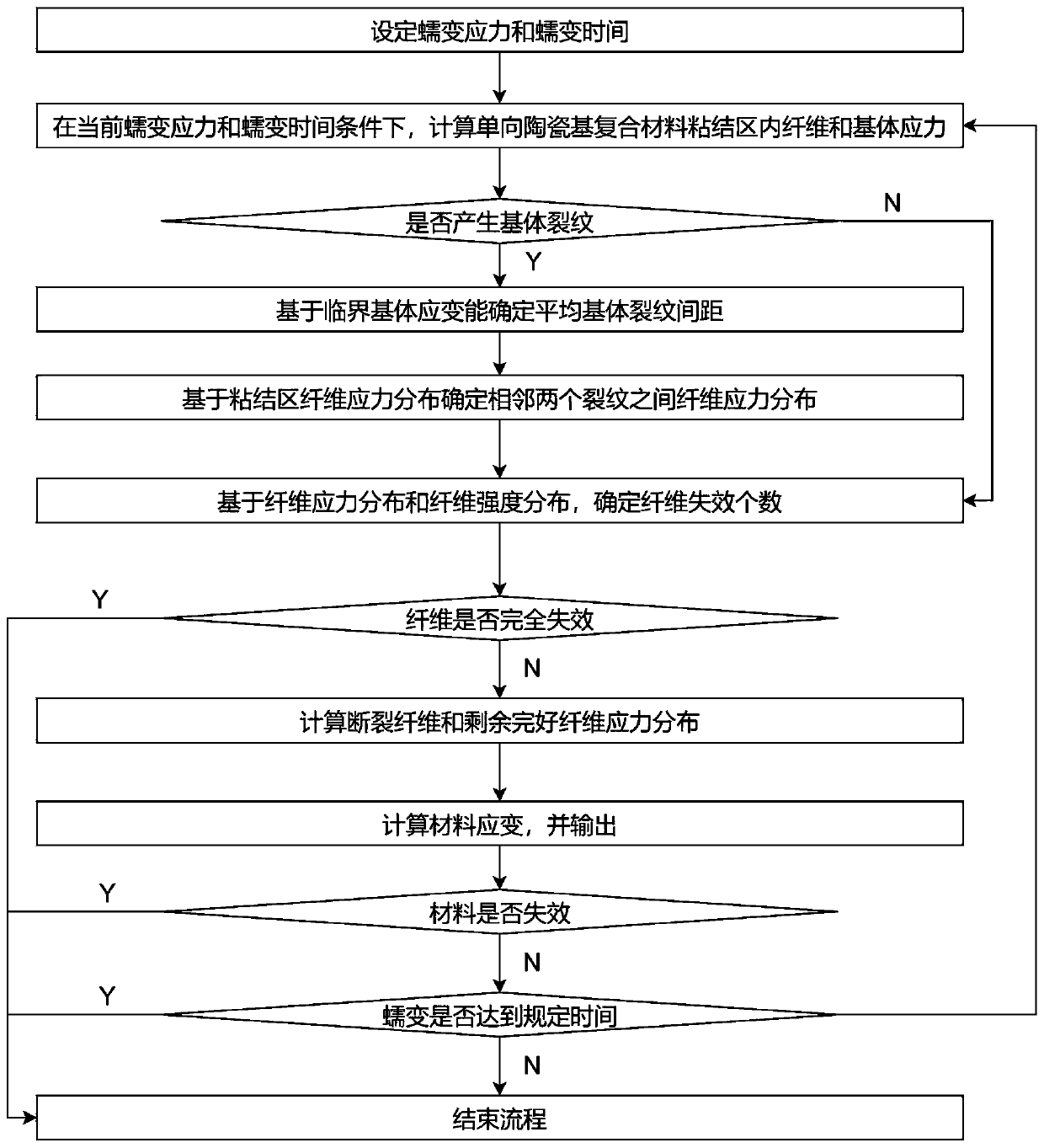

[0069] combine figure 1 , the present invention proposes a method for predicting the creep behavior of unidirectional ceramic matrix composites, comprising the following steps:

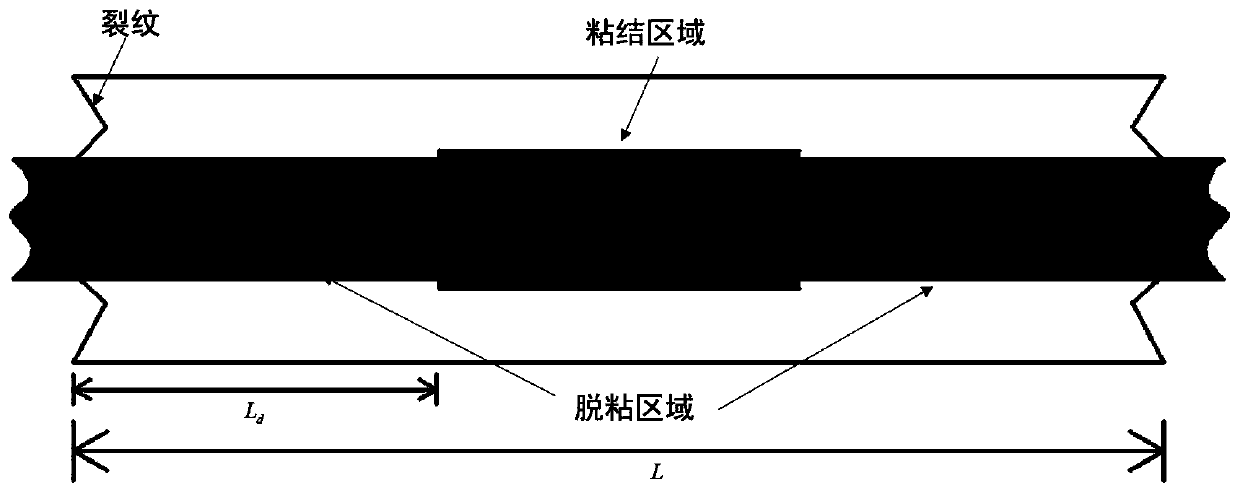

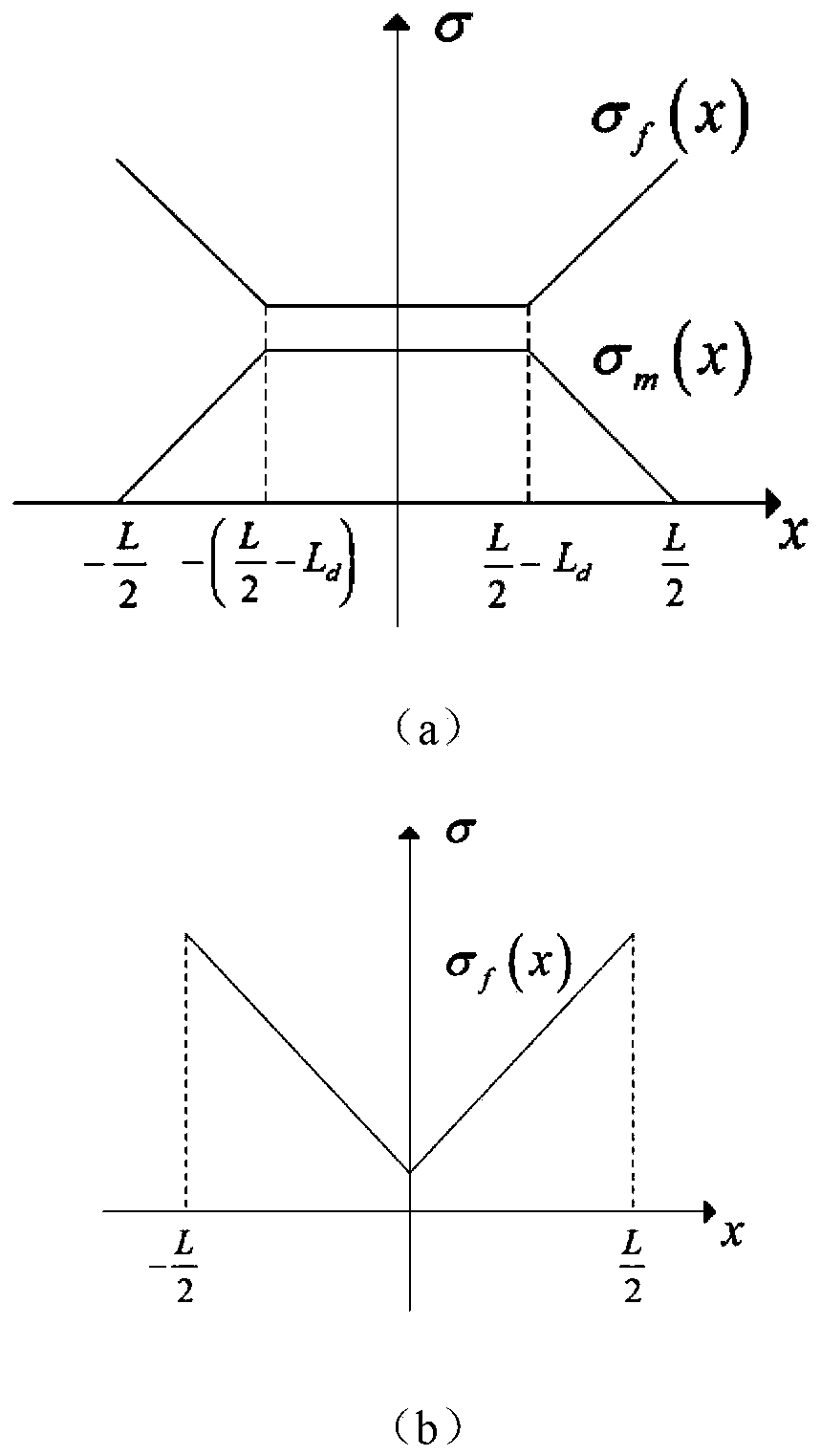

[0070] (1) For a certain creep stress and creep time, the fiber and matrix stress in the bonding zone of the unidirectional ceramic matrix composite is obtained. During the creep process of unidirectional ceramic matrix composites, assuming that the fiber and matrix strains in the bonded region are the same, the stresses of the fibers and matrix in the bonded region satisfy the following equations:

[0071]

[0072] Among them, σ f0 ,σ m0 are the fiber and matrix stresses in the bonding zone, respectively, E f ,E m is the elastic modulus of fiber and matrix, v f .v m are the volume fractions of fibers and matrix,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com