Projection Screens and Projection Systems

A projection screen and projection technology, applied in the field of projection systems, can solve the problems that the screen cannot be shared by telephoto projectors and ultra-short-focus projectors, increase user cost, reduce space utilization, etc., and achieve a good effect against ambient light. , Improve contrast, increase the effect of horizontal viewing angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0054] 1.1 Structure overview

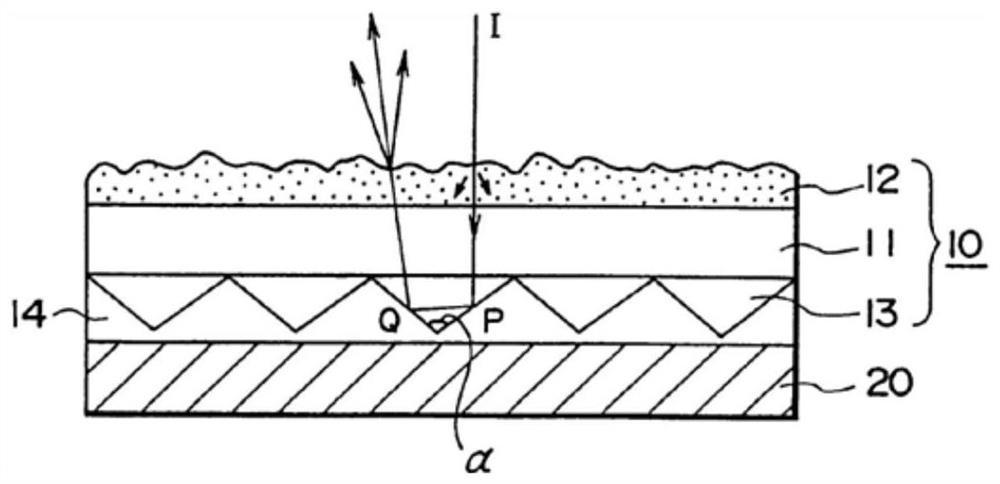

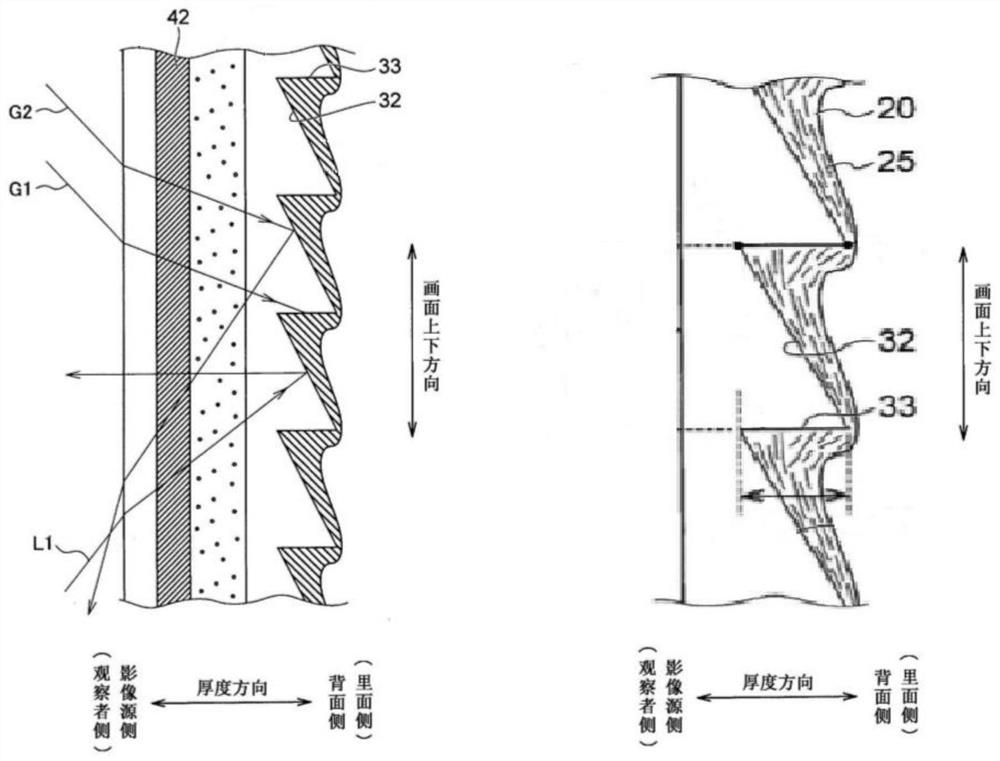

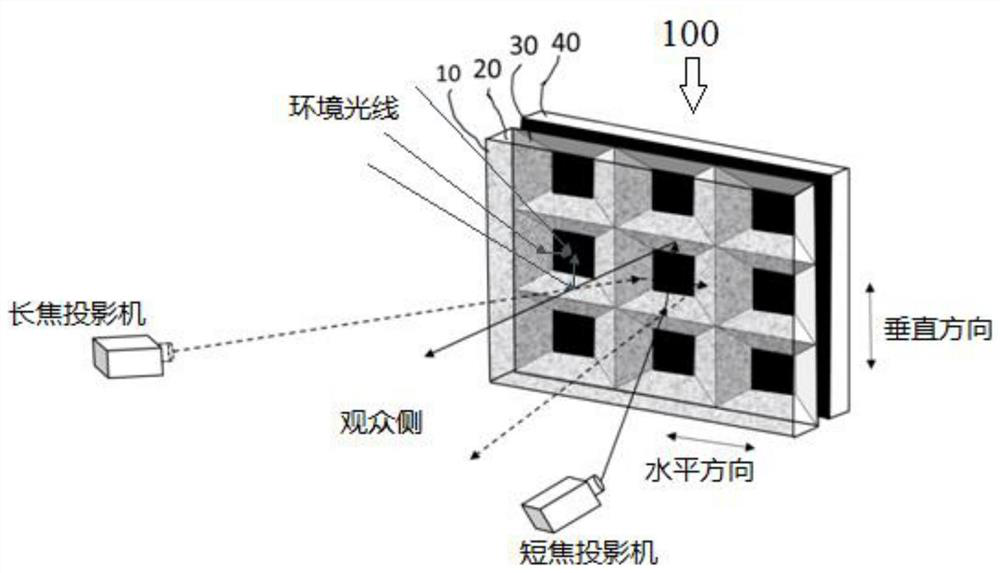

[0055] image 3 is a schematic diagram showing the structure of the projection screen according to the first embodiment of the present invention. Such as image 3 As shown in , the projection screen 100 includes a light diffusing layer 10 , a substrate layer 20 , a reflective layer 30 and a light absorbing layer 40 arranged sequentially from the viewer side (ie, the incident side of projection light). The reflective layer 30 is provided with a plurality of microstructure units, and these microstructure units are arranged in a two-dimensional manner to form a microstructure unit array. The microstructure unit may be formed on the side of the substrate layer 20 facing away from the viewer by coating resin on the roll and UV curing process. In other words, the reflective layer 30 and the substrate layer 20 may be integrally formed. The light can pass through the light diffusing layer 10 and the substrate layer 20 in sequence to reach the reflec...

no. 2 example

[0110] The following will refer to Figure 21 to Figure 25 A projection screen according to a second embodiment of the present invention is explained.

[0111] Figure 21 is a perspective view showing a projection screen according to a second embodiment of the present invention. Such as Figure 21 As shown in , the projection screen 200 includes a light diffusing layer 10 , a substrate layer 20 , a reflective layer 30 and a light absorbing layer 40 arranged sequentially from the viewer side (ie, the incident side of projection light). The reflective layer 30 is provided with a plurality of microstructure units, and these microstructure units are arranged in a two-dimensional manner to form a microstructure unit array. The difference between the projection screen 200 of the second embodiment and the projection screen 100 of the first embodiment mainly lies in the specific structure of the reflective microstructure unit. Such as Figure 21 and Figure 22 As shown in , the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com