Directional tail cutting machine for margarya melanioides

A technology of tail cutting machine and snails, which is applied in the field of machinery, can solve the problems of labor-intensive, snail tails cutting cannot be carried out in large quantities, etc., and achieve the effect of high tail cutting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

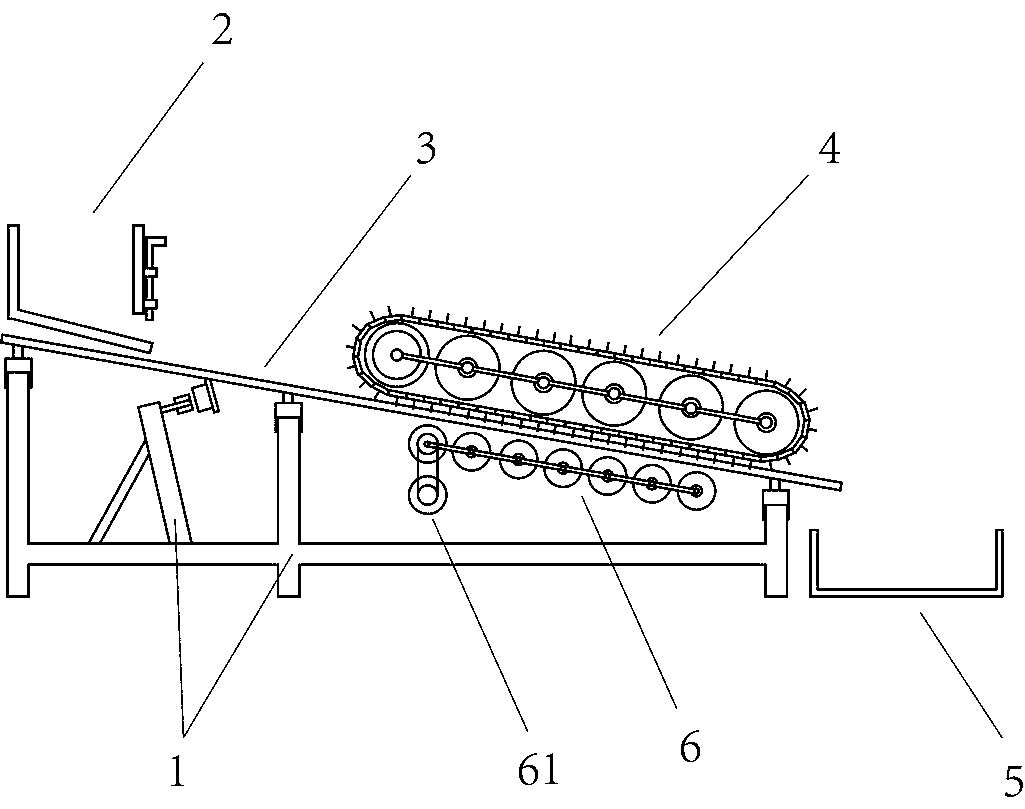

[0048] A snail directional tail-cutting machine is used for tail-cutting of square ring snails. A base 1 is arranged below, the hopper 2 and screw setter 4 are arranged above the conveyor table 3, the cutting wheel 6 is arranged below the conveyor table 3, and a receiving tray 5 is arranged at the tail of the conveyor table 3;

[0049] When the equipment is in operation, the snails 7 come out from the hopper 2 and enter the conveying platform 3, arrange the direction through the conveying platform 3, and reach the bottom of the screw setter 4, after being fixed by the screw setter 4, the snails are removed by the cutting wheel 6, and then reach the tail of the conveying platform 3 Fall into the receiving tray 5;

[0050] The hopper 2 includes: a discharge port 11, a twitching plate 12, a tightening knob 13 and a hopper bottom 14, the hopper 2 is connected to the base 1, the twitching plate 12 is arranged on the discharge port 11, and is fixed on the hopper by the tightening kn...

Embodiment 2

[0056] A snail directional tail-cutting machine is used for tail-cutting of square ring snails. A base 1 is arranged below, the hopper 2 and screw setter 4 are arranged above the conveyor table 3, the cutting wheel 6 is arranged below the conveyor table 3, and a receiving tray 5 is arranged at the tail of the conveyor table 3;

[0057] When the equipment is in operation, the snails 7 come out from the hopper 2 and enter the conveying platform 3, arrange the direction through the conveying platform 3, and reach the bottom of the screw setter 4, after being fixed by the screw setter 4, the snails are removed by the cutting wheel 6, and then reach the tail of the conveying platform 3 Fall into the receiving tray 5;

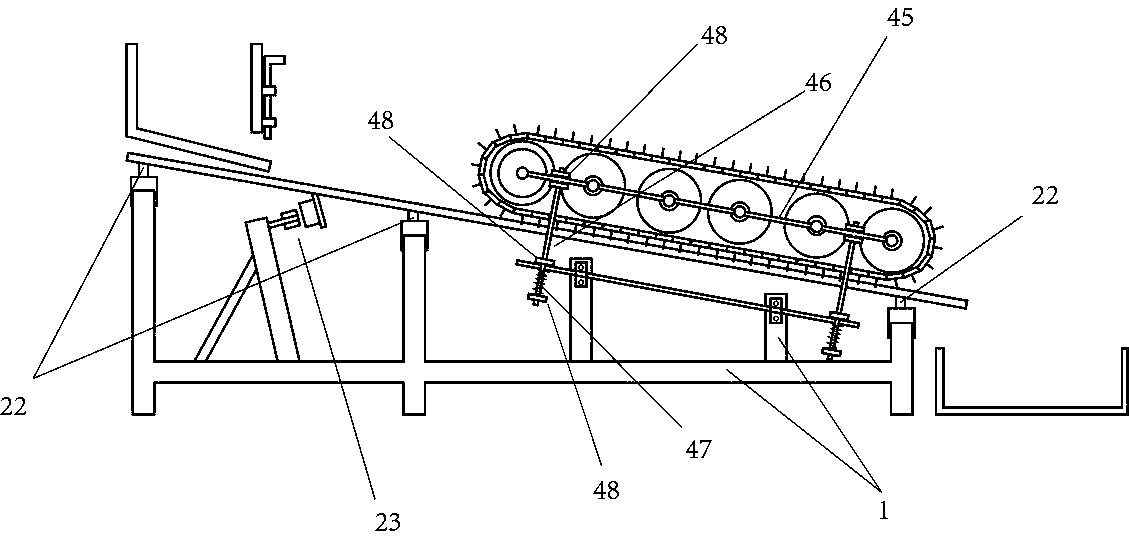

[0058] The conveying table 3 includes: a conveying plate 21, an elastic device 22, and a vibrating device 23. The conveying plate 21 is inclined and has a certain slope. The upper part of the conveying plate 21 is a flat plate 24, the lower part is a fence-type part...

Embodiment 3

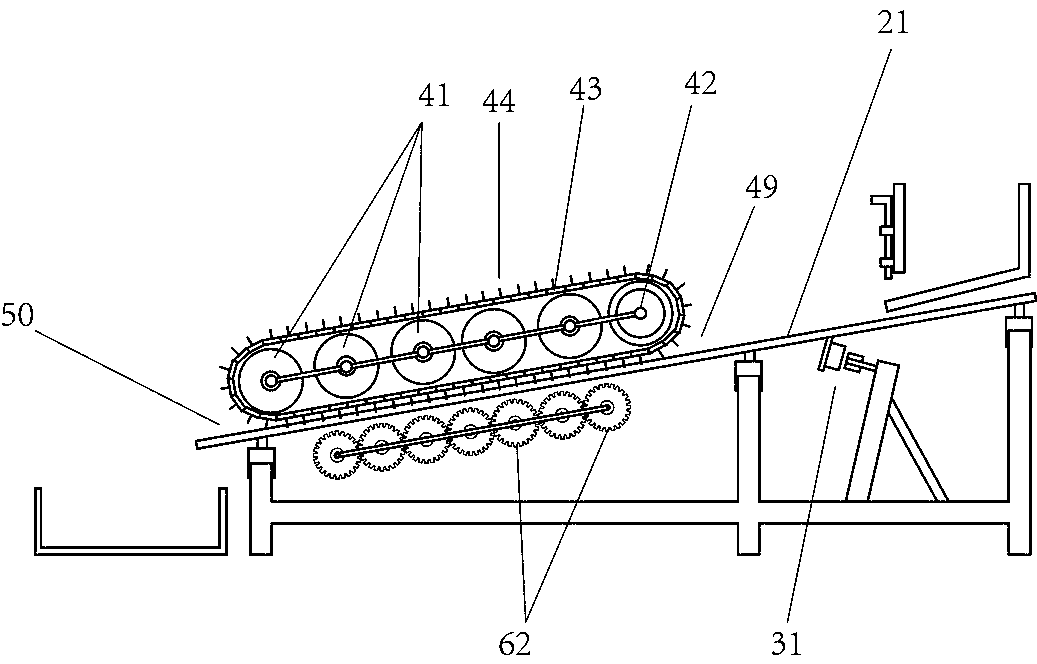

[0063] A directional tail-cutting machine for snails, which is used for cutting tails of green snails in Kaihua, comprising: a base 1, a hopper 2, a conveying platform 3, a screwdriver 4, a receiving tray 5, and a cutting wheel 6, and the conveying platform 3 is below the The base 1 is set, the hopper 2 and screw setter 4 are arranged above the conveying platform 3, the cutting wheel 6 is arranged below the conveying platform 3, and the receiving tray 5 is arranged at the tail of the conveying platform 3;

[0064] When the equipment is in operation, the snails 7 come out from the hopper 2 and enter the conveying platform 3, arrange the direction through the conveying platform 3, and reach the bottom of the screw setter 4, after being fixed by the screw setter 4, the snails are removed by the cutting wheel 6, and then reach the tail of the conveying platform 3 Fall into the receiving tray 5;

[0065] The hopper 2 includes: a discharge port 11, a twitching plate 12, a tightening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com