Chimney white smoke low-energy-consumption treatment method

A technology with low energy consumption and white smoke, applied in the fields of energy and environmental protection, can solve problems such as corrosion, large maintenance costs, and large energy costs, and achieve the effects of reducing energy consumption, reducing the content of harmful substances discharged outside, and eliminating white smoke from chimneys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

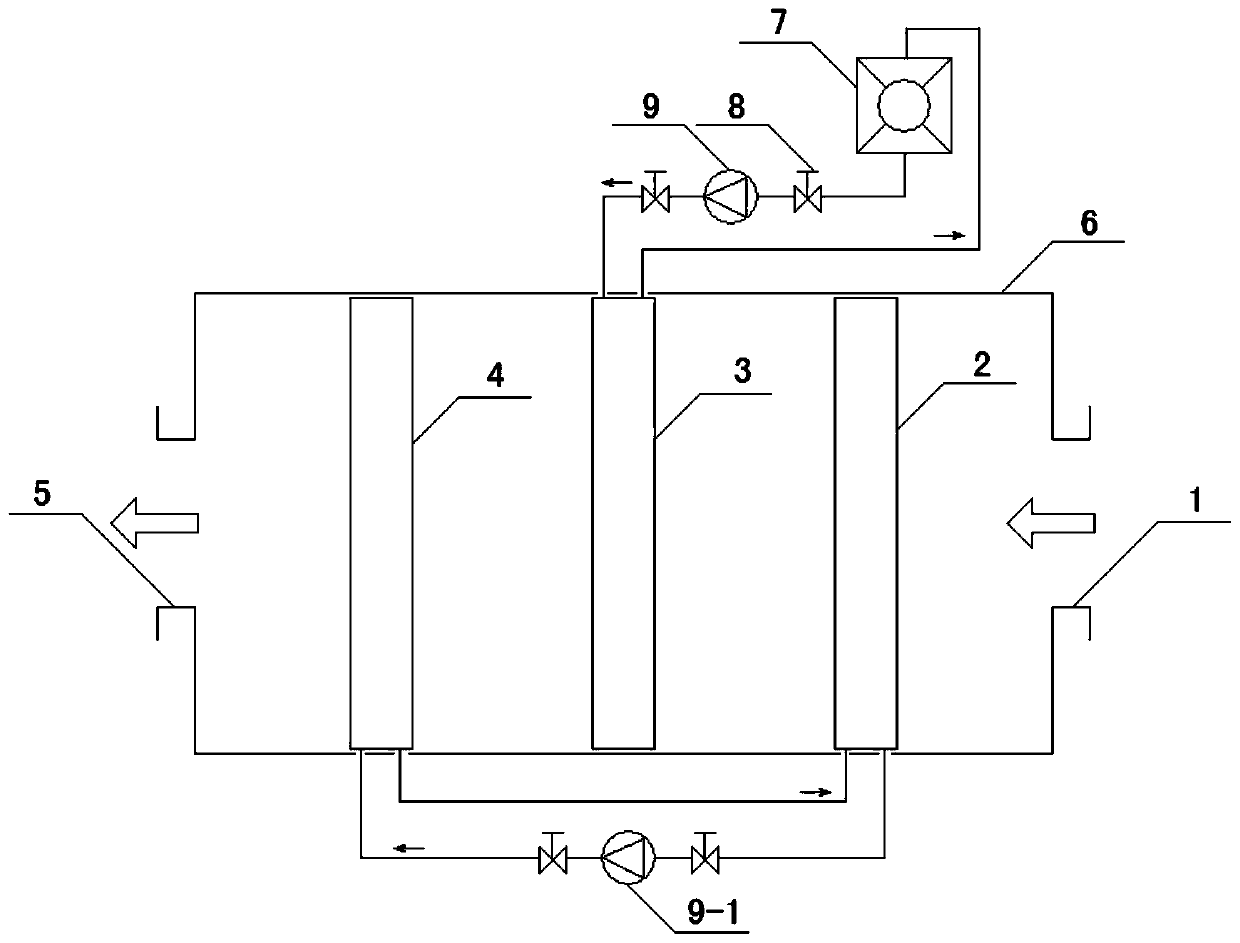

[0034] Implementation case one, such as figure 1 As shown, this case is a schematic diagram of a system in which the cold source is a cooling tower, in which: when the clean flue gas passes through the first heat exchange device 2, the temperature and moisture content are initially reduced, and then enters the second heat exchange device 3, and is cooled by the cooling tower. After cooling, the temperature and moisture content of the flue gas are further reduced, and then enter the third heat exchange device 4 to be heated and discharged after reducing the relative humidity, so as to achieve the purpose of eliminating white smoke.

[0035] Among them: under the action of the circulation pump 9-1 of the first and third heat exchange devices, the third heat exchange device 4 recovers the cooling capacity of the flue gas after the cooling of the second heat exchange device 3 as the cooling source of the first heat exchange device 2 , and the first heat exchange device 2 recovers ...

Embodiment example 2

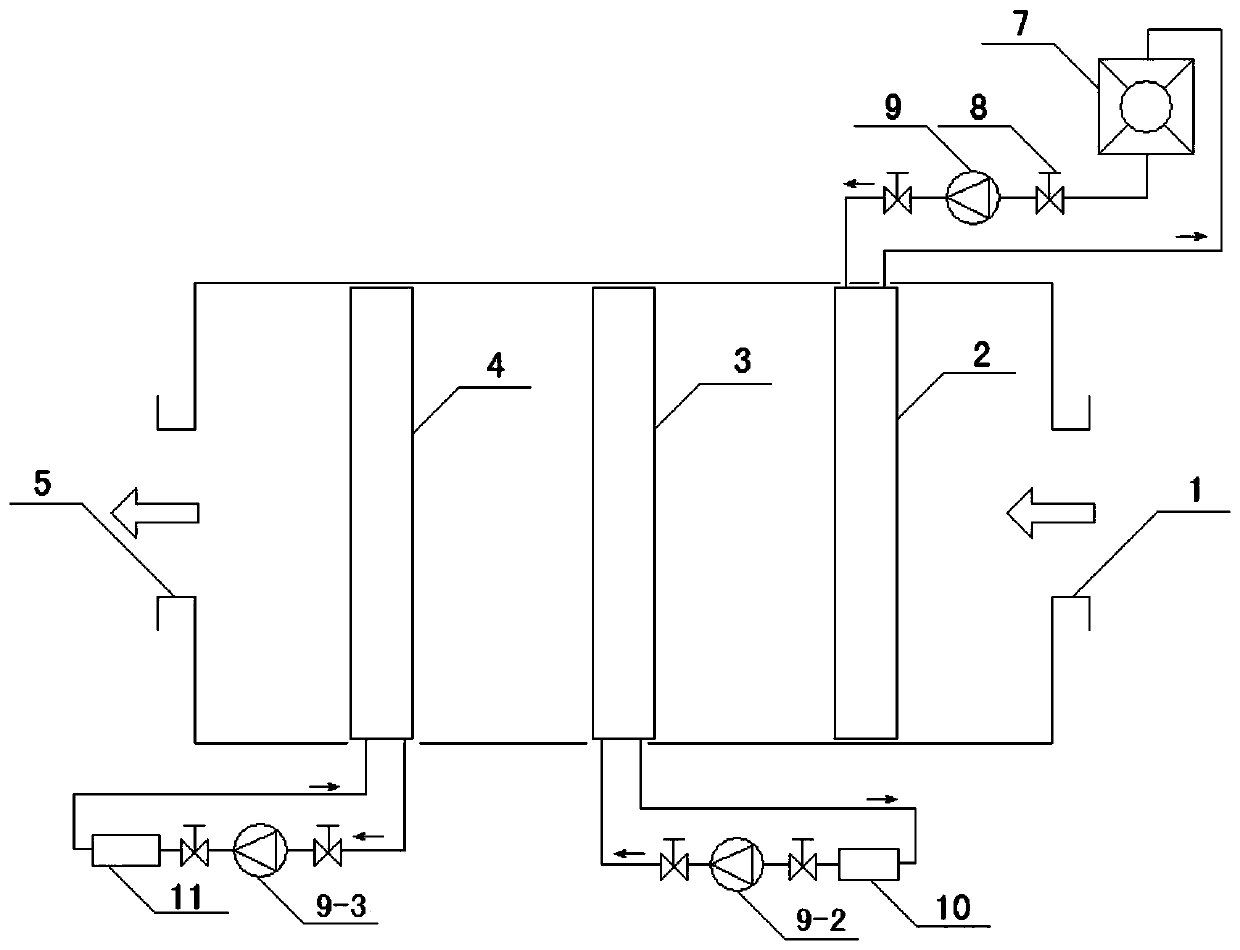

[0036] Implementation case two, such as figure 2As shown, this case is one of the schematic diagrams of a composite system in which the cold source is a cooling tower and a refrigeration unit. When the clean flue gas passes through the first heat exchange device 2, the temperature and moisture content are initially reduced by the cooling tower 7, and then enter the second heat exchange device. The heat device 3 is provided by the refrigerating unit evaporator 10 connected to the refrigerating unit (not shown in this part of the drawings, the same below) to further reduce the temperature and moisture content, and then enter the third heat exchange device 4, which is connected with the refrigerating unit The condenser 11 of the refrigerating unit connected to the unit (this part is not shown in the drawings, the same below) provides heat to increase the temperature of the flue gas, reduce the relative humidity of the flue gas, and achieve the purpose of eliminating white smoke. ...

Embodiment example 3

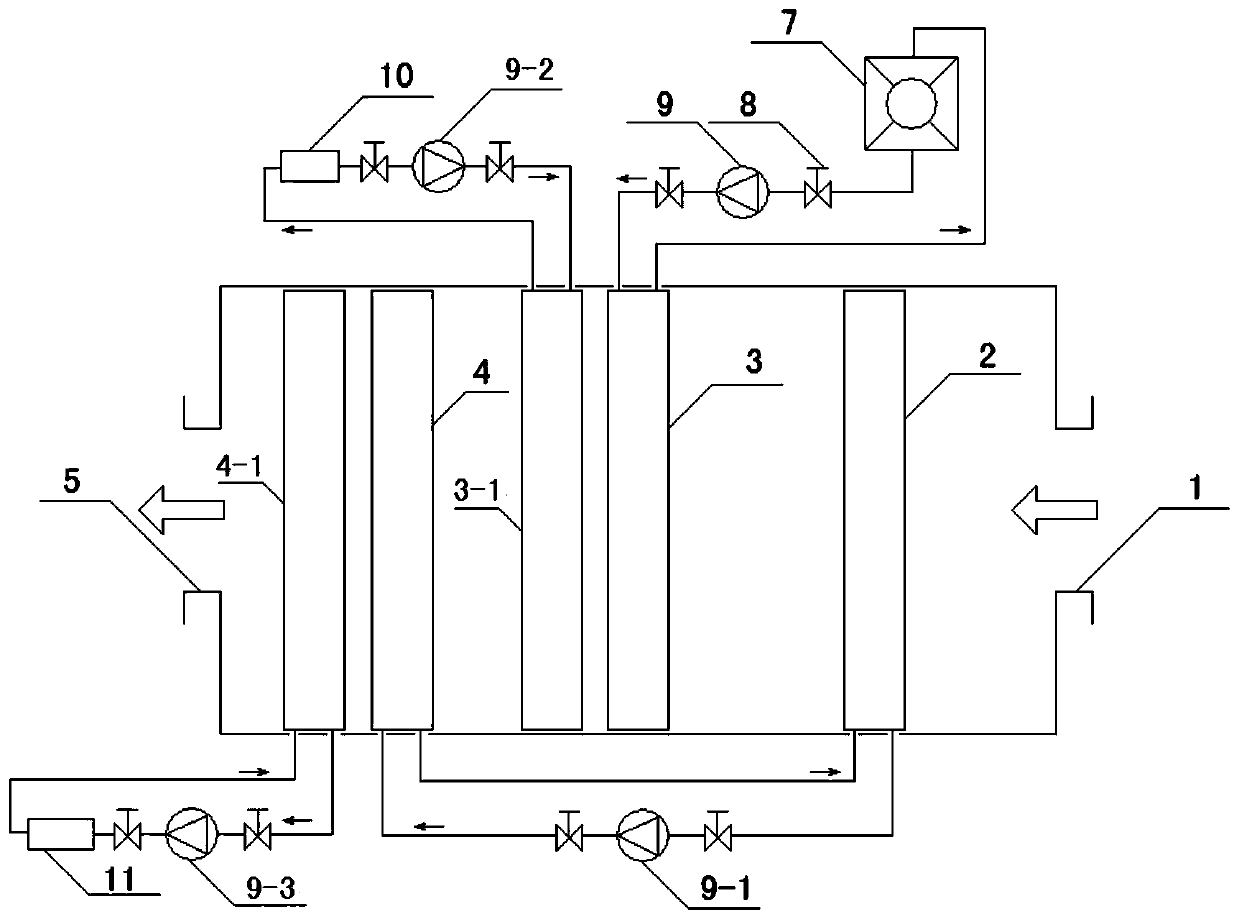

[0039] Implementation case three, such as image 3 As shown, this case is the second schematic diagram of a composite system in which the cold source is a cooling tower and a refrigeration unit. When the net flue gas passes through the first heat exchange device 2, the temperature and moisture content are initially reduced, and then enters the cooling tower 7 for circulation cooling. The second heat exchange device 3 connected to the system, and the second heat exchange device 3-1 connected to the evaporator 10 of the refrigeration unit connected to the refrigeration unit (not shown in this part of the drawings) jointly further reduce the temperature and moisture content, Then enter the third heat exchange device 4 and 4-1 to increase the temperature of the flue gas and reduce the relative humidity of the flue gas to achieve the purpose of eliminating white smoke.

[0040] Among them: under the action of the circulation pump 9-1 of the first and third heat exchange devices, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com