Catalyst for removing nitrogen oxide in FCC stack gas at low temperature and production method thereof

A technology for regenerating flue gas and nitrogen oxides, which is applied in the field of catalysis and can solve problems such as poor removal activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] ① Take 100g Fe 2 o 3 , 30g MnO 2 , 30g CuO kneaded evenly; ②Roast the kneaded material at 300℃~450℃ for 2h~4h; ③Put the roasted material in a colloid mill and add an appropriate amount of water to grind it into a stable slurry with good fluidity; Immerse 100g cordierite honeycomb carrier in the above slurry for 0.5h~1h, take it out and dry it at 100℃~120℃ for more than 12h, and then bake it at 300℃~450℃ for 2h~4h; ⑤Repeat step ④until the weight of the carrier increases by 20g , the prepared catalyst I.

Embodiment 2

[0022] ①Take 100g TiO2 2 , 30g Cr 2 o 3 , 30g CuO kneaded evenly; ②Roast the kneaded material at 300℃~450℃ for 2h~4h; ③Put the roasted material in a colloid mill and add an appropriate amount of water to grind it into a stable slurry with good fluidity; Immerse 100g cordierite honeycomb carrier in the above slurry for 0.5h~1h, take it out and dry it at 100℃~120℃ for more than 12h, and then bake it at 300℃~450℃ for 2h~4h; ⑤Repeat step ④ until the weight of the carrier increases by 40g , the prepared catalyst II.

Embodiment 3

[0024] ① Take equivalent to 100g Fe 2 o 3 of ferric nitrate, equivalent to 20g MnO 2 Manganese nitrate equivalent to 30g CuO and copper nitrate equivalent to 30g CuO were dissolved in water to prepare a mixed solution; ②Immerse 100g cordierite honeycomb carrier in the above solution for 0.5h~1h, take it out and dry it at 100℃~120℃ for more than 12h, then Calcining at 300°C-450°C for 2h-4h; ③repeating step ②until the weight of the carrier increases by 40g, and the prepared catalyst III is obtained.

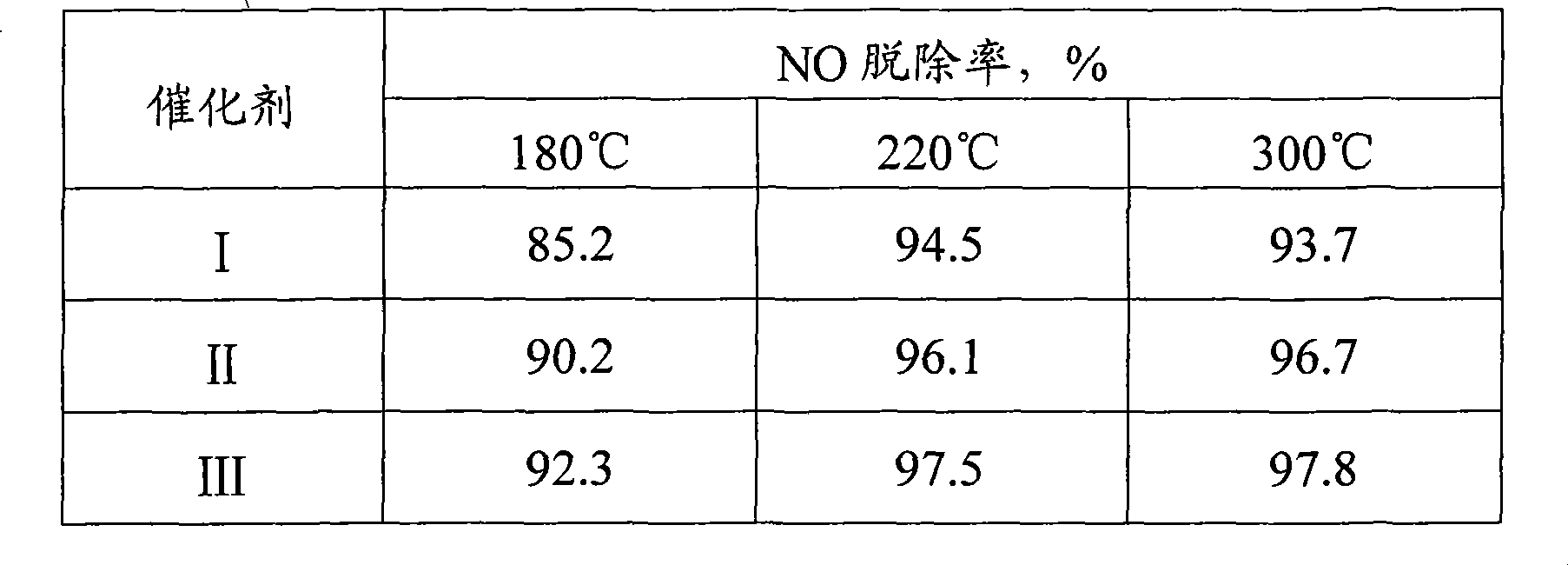

[0025] The above-mentioned catalysts were packed in a fixed-bed reactor (filling volume: 2 mL) for activity determination. Feed containing NO500ppm, O 2 3%, n (NH3) / n (NO) 1.0 feed gas (N 2 For the balance gas), the reaction space velocity is 5000h -1 , the reaction pressure is 0.1MPa, and the reaction temperature is 180°C-300°C for NO selective catalytic reduction reaction, and the NO content in the inlet and outlet gas of the reactor is detected online with a trace NO ana...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com