Temperature compensation type high-precision calibration method for soil salinity sensor

A technology of salinity sensor and temperature compensation, applied in the field of measurement, can solve the problems of no temperature compensation coefficient, small coverage, small number of measurement points, etc., to achieve accurate and reliable temperature compensation value, absolute accuracy of temperature environment, and refined compensation coefficient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

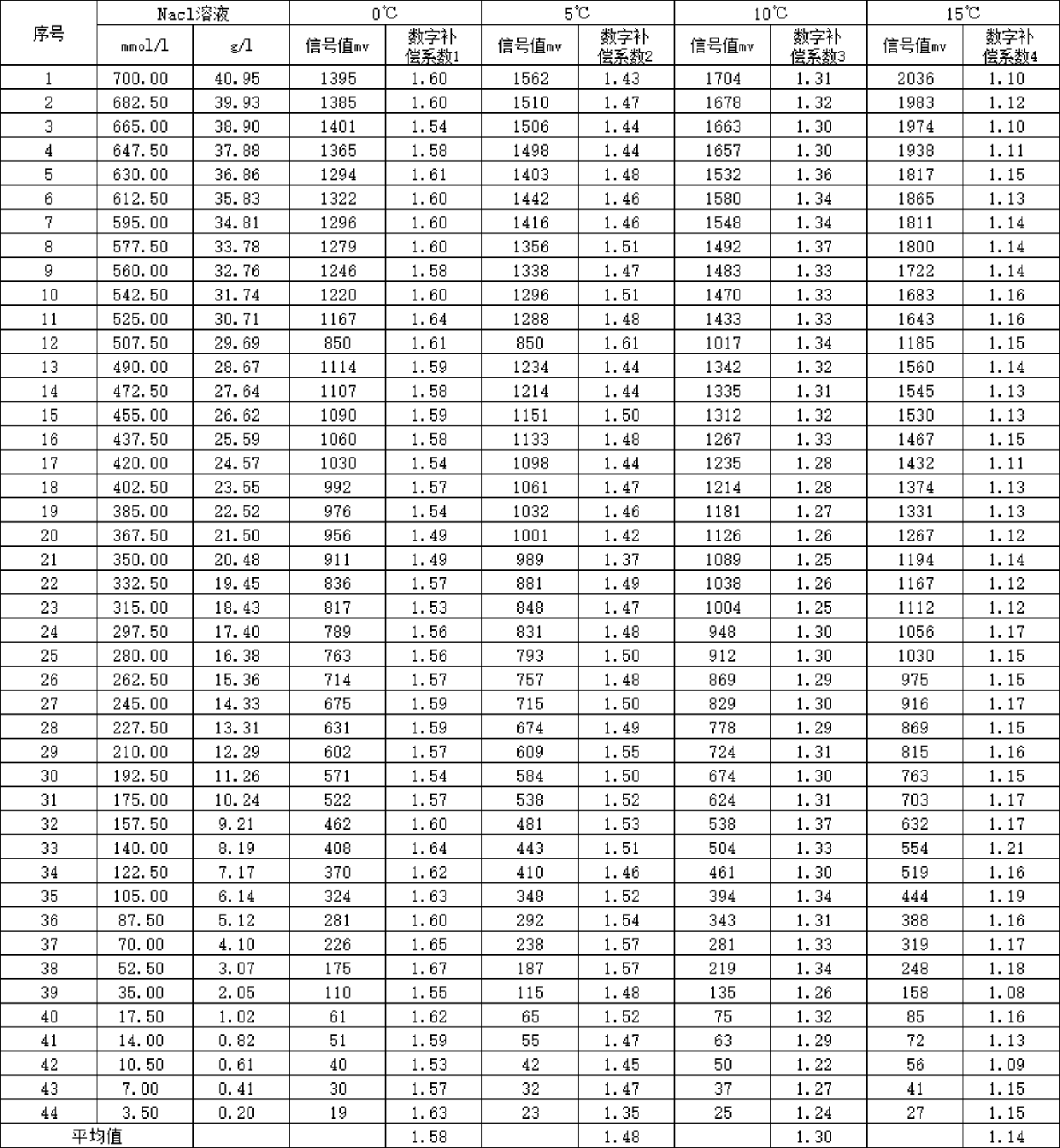

[0029] In order to further understand the present invention, the preferred embodiments of the present invention will be described below in combination with specific implementations. In the following examples, the calibration of the soil salinity sensor in the coastal experimental base laboratory of Jiangsu Institute of Water Resources Research is taken as an example. The sensor is developed by Wuhan Midnet Technology Co., Ltd.'s XML001 soil salinity sensor.

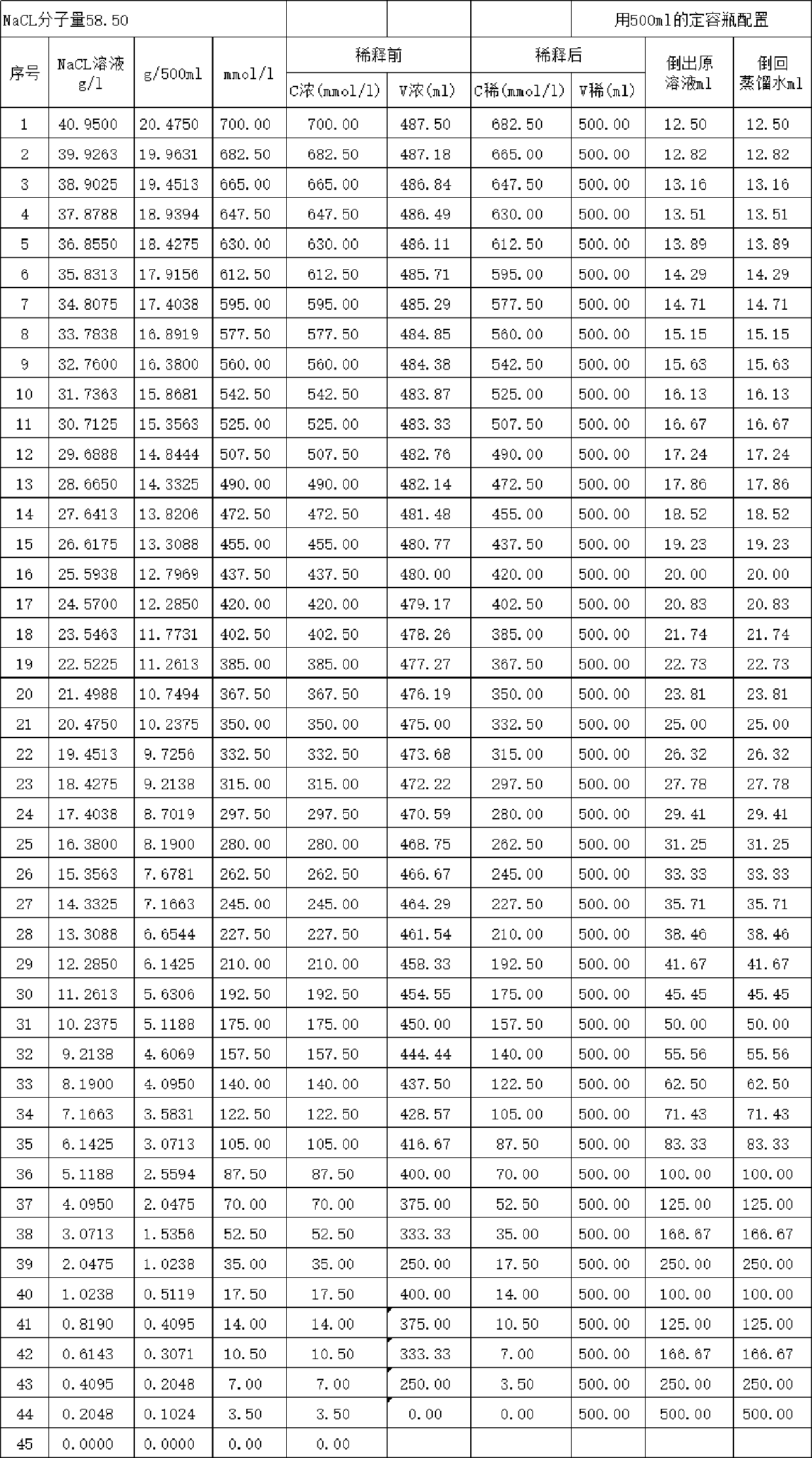

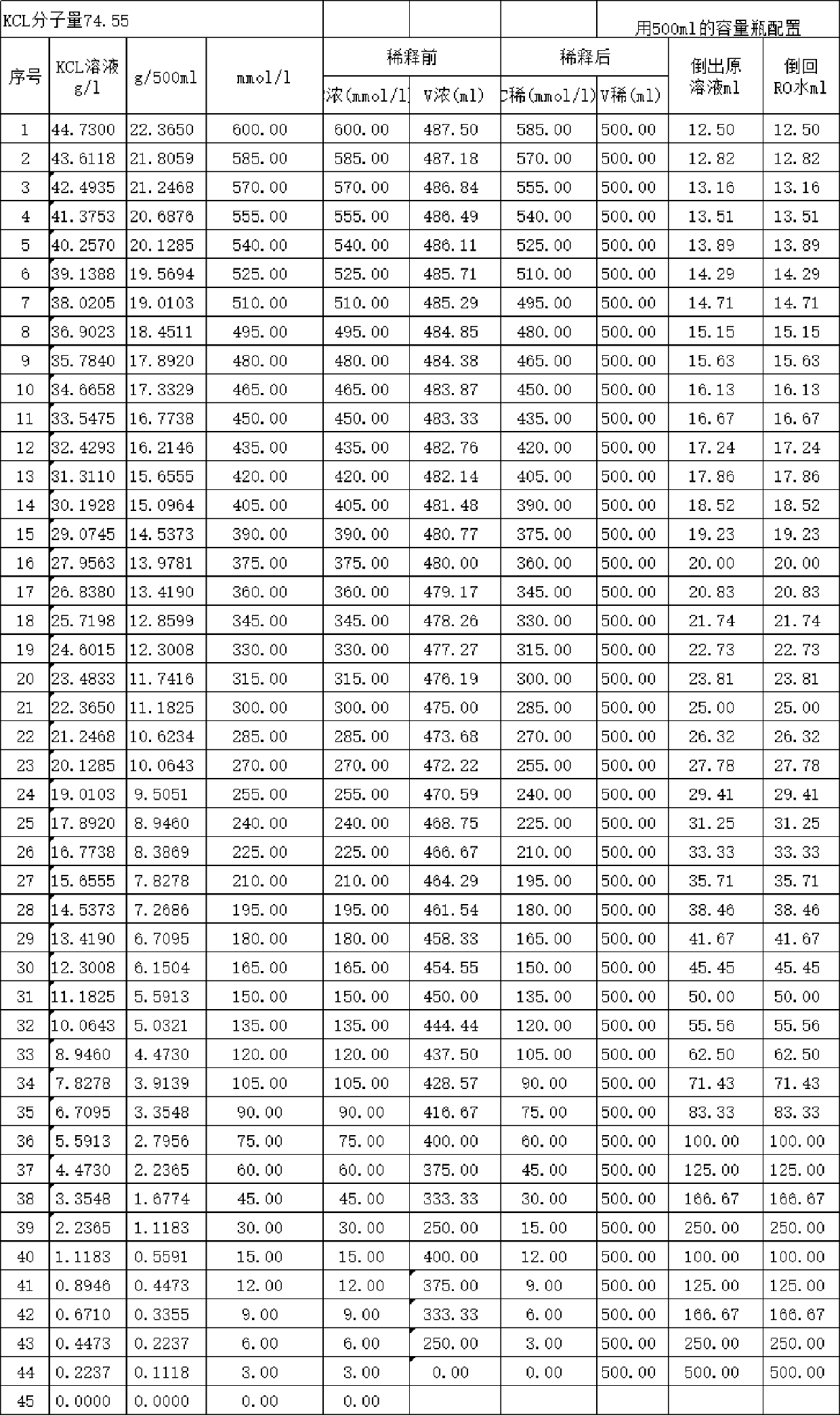

[0030] Step 1. According to the main salt composition of the soil in the use area, determine to prepare the corresponding salt solution as the calibration solution, and use the NaCl salt solute to prepare the standard salt solution.

[0031] Step 2: Adjust the indoor air-conditioning temperature, keep the indoor temperature at 25℃, prepare the highest salt solution, and then prepare a gradient standard salt solution according to the dilution method. The highest salt solution uses seawater with a maximum concentration of approxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com