High-precision simple calibration method for soil moisture sensor

A soil moisture and sensor technology, applied in the field of measurement, can solve the problems of many human intervention actions, low degree of automation, and large workload, and achieve the effect of high degree of automation, low labor cost, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention provides a simple and high-precision calibration method for a soil moisture sensor. In the following examples, the calibration of the soil moisture sensor in the laboratory of the coastal experiment base of the Jiangsu Academy of Hydraulic Sciences is taken as an example.

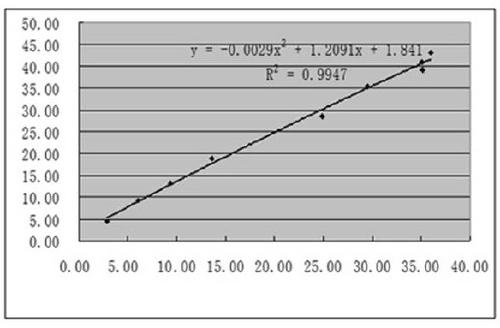

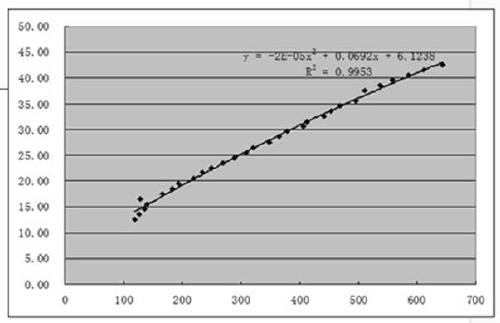

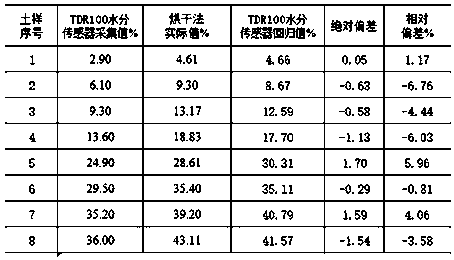

[0020] Step 1: Determine a standard soil moisture sensor. The standard soil moisture sensor is the TDR100 soil moisture sensor from Campbell in the United States. Do a calibration experiment with this sensor and the recognized standard soil drying method. First, configure 8 gradients with different moisture contents Sample soil, configure the sample soil with water content of 5%, 10%, 15%, 20%, 25%, 30%, 35%, 40%, the actual soil water content measured by the soil drying method, record the sensor corresponding to each For the output value of the sample soil, see the attached figure 1 . Calculate the fitting formula between the output value of the soil moisture sensor and the ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| verticality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com