Ultrasonic positioning method for partial discharge fault point of traction transformer

A traction transformer and partial discharge technology, applied in positioning, instrumentation, testing dielectric strength, etc., can solve the problem of large partial discharge positioning error, complex structure of traction transformer, and difficulty in distinguishing ultrasonic signal propagation paths as direct paths or indirect paths, etc. problem, to achieve the effect of improving the accuracy of discharge positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

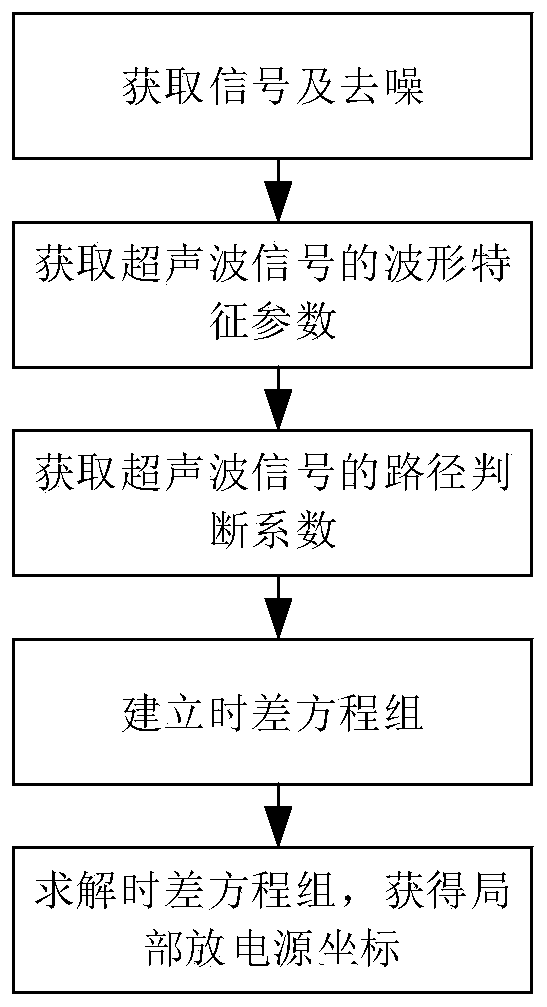

[0033] The implementation process of the present invention will be further described in detail below in conjunction with the accompanying drawings and cases.

[0034] The first step is to obtain the ultrasonic signal and denoise:

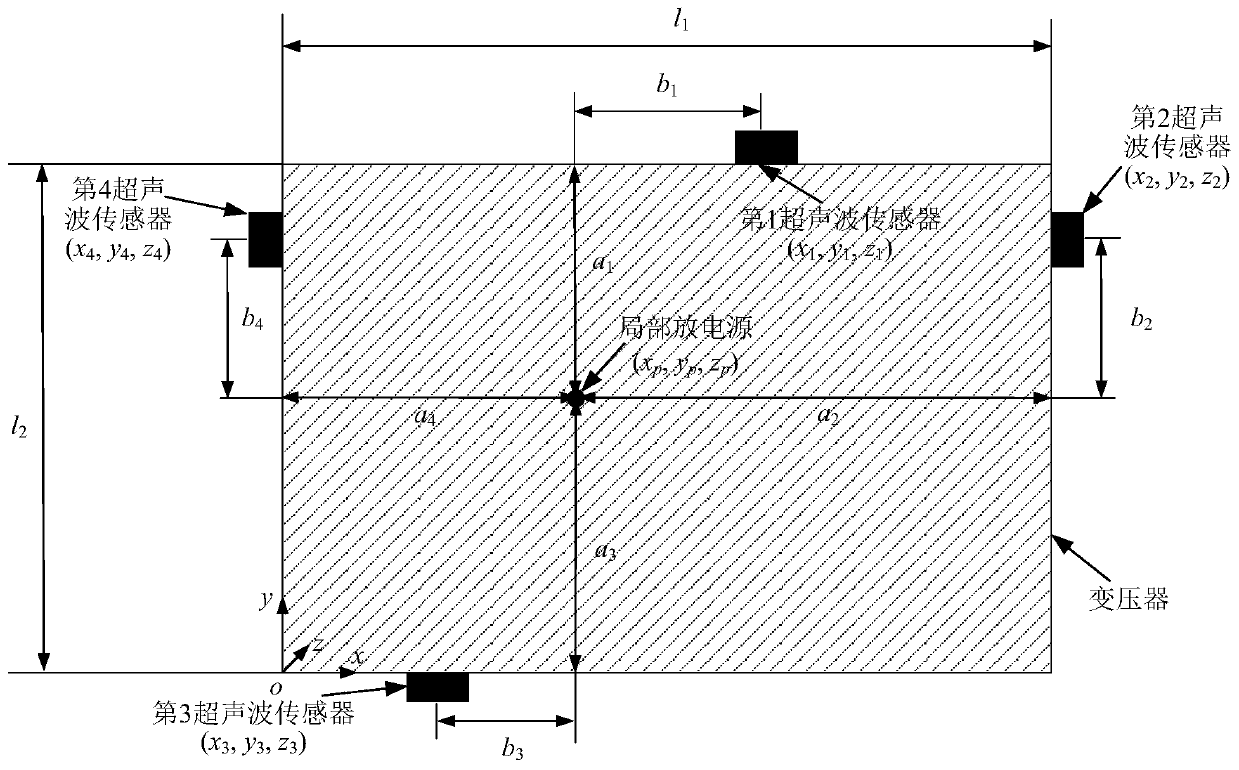

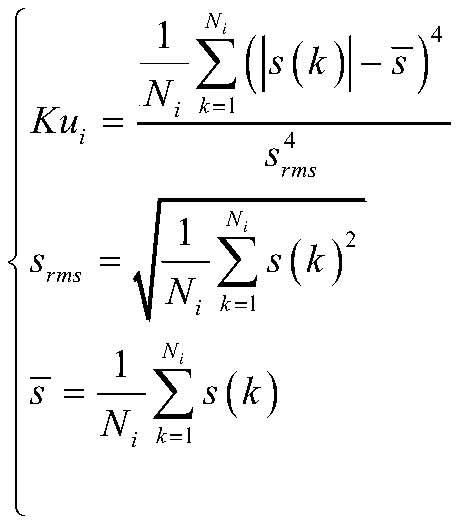

[0035] Obtain the ultrasonic signal s received by the four ultrasonic sensors i , wherein i=1,2,3,4 is the serial number of the ultrasonic sensor; s 1 is the ultrasonic signal received by the first ultrasonic sensor, s 2 is the ultrasonic signal received by the second ultrasonic sensor, s 3 is the ultrasonic signal received by the third ultrasonic sensor, s 4 Be the ultrasonic signal that the 4th ultrasonic sensor receives;

[0036] The coordinates of the first ultrasonic sensor are (x 1 ,y 1 ,z 1 ), the coordinates of the second ultrasonic sensor are (x 2 ,y 2 ,z 2 ), the coordinates of the third ultrasonic sensor are (x 3 ,y 3 ,z 3 ), the coordinates of the fourth ultrasonic sensor are (x 4 ,y 4 ,z 4 ), the coordinates of the parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com