Automatic feeding article storage rack

A technology for item storage and automatic loading, applied to shelves, household appliances, applications, etc., can solve problems such as high labor intensity and cost, poor material identification and management ability, and complex types, so as to improve flexibility, reliability, and good quality. The effect of bearing positioning capacity and high degree of operation automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below in conjunction with specific embodiments.

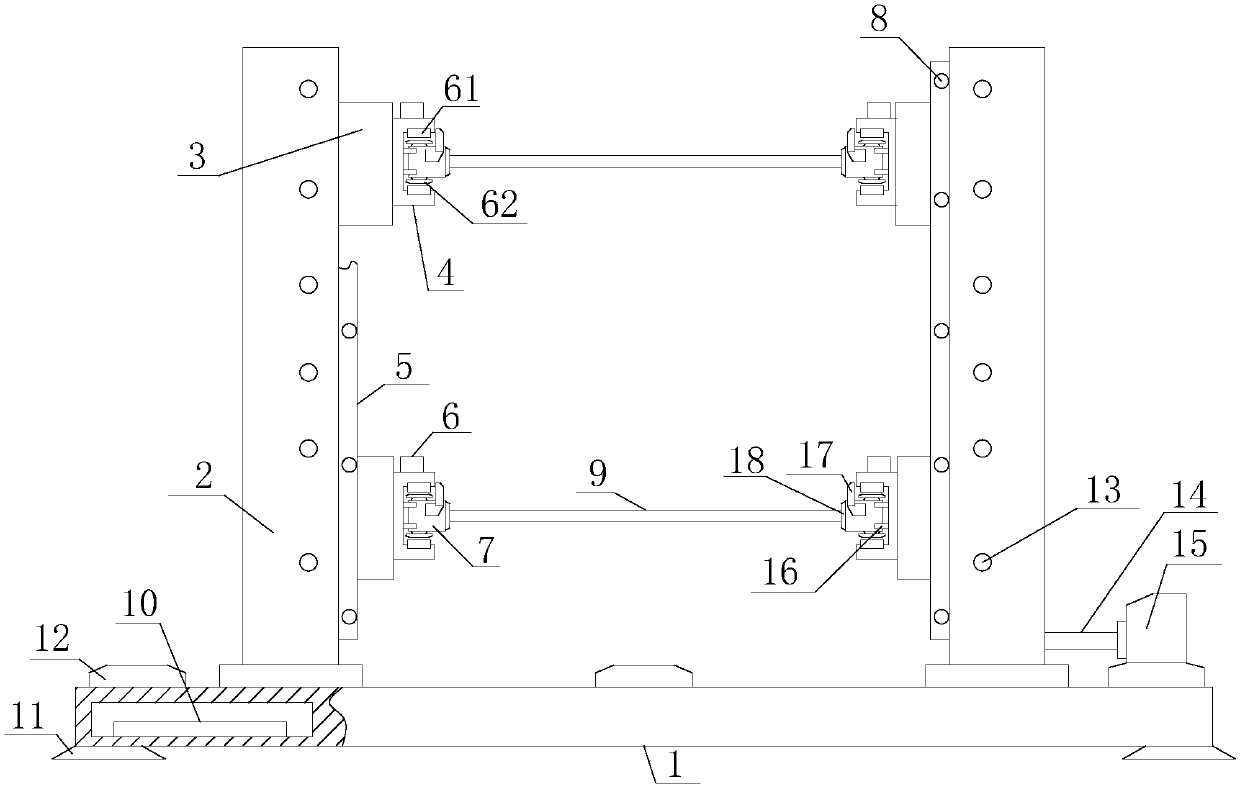

[0015] Such as figure 1 The described storage rack for automatically feeding articles includes a bearing base 1, a bearing column 2, a horizontal beam 3, a horizontal guide rail 4, a vertical guide rail 5, a linear motor 6, a slider 7, an in-position sensor 8, and a bearing plate 9 and control circuit 10, the carrying base 1 is a closed cavity structure with a rectangular cross section, at least four positioning mechanisms 11 are uniformly distributed on the lower surface of the supporting base 1, at least four supporting pillars 2 are uniformly distributed on the upper surface, and each supporting pillar 2 It is evenly distributed around the axis of the bearing base 1 and vertically distributed to the upper surface of the bearing base 1. At least four h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com