Double-head bottle opener

A bottle opener and double-head technology, applied in the field of bottle openers, can solve problems such as detachment, achieve the effect of convenient operation and increase the speed of bottle opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

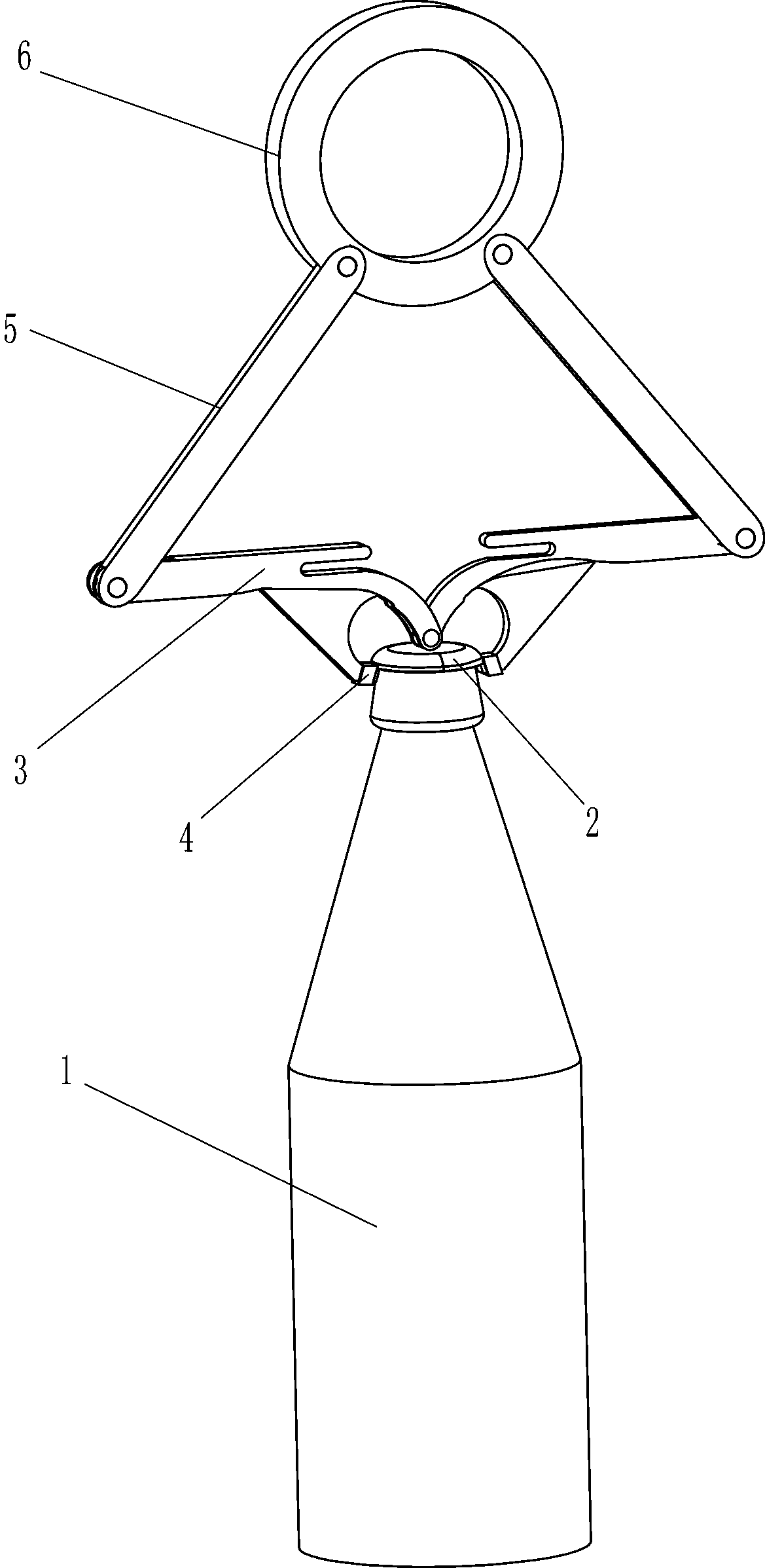

[0026] A double-headed corkscrew, such as Figure 1-2 As shown, it includes a double-headed swing rod 3, a clamping mechanism 4, a connecting rod 5 and a ring 6. The left and right sides of the lower part of the ring 6 are rotatably provided with a connecting rod 5, and the end of the connecting rod 5 is rotatably connected with a double-headed The swing rod 3 is rotationally connected in the middle of the double-headed swing rod 3 , and the left and right sides of the bottom of the double-headed swing rod 3 are provided with clamping mechanisms 4 .

[0027] When people need to use this device to open the bottle cap 2, clamp the clamping mechanism 4 of the device on the bottle body below the bottle cap 2, hold the bottle body 1 at the bottom with one hand, and hold the ring 6 with the other hand Lifting upward, the ring 6 drives the connecting rod 5 to move upward, and the connecting rod 5 drives the outer end of the double-ended swing rod 3 to move upward. With the contact po...

Embodiment 2

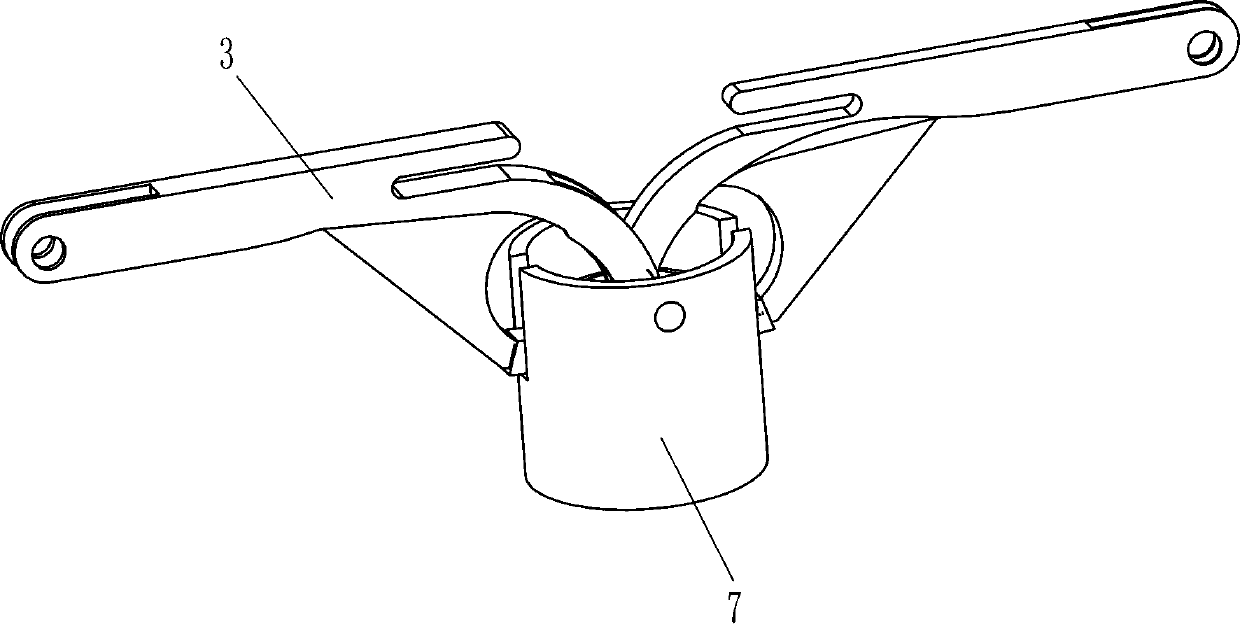

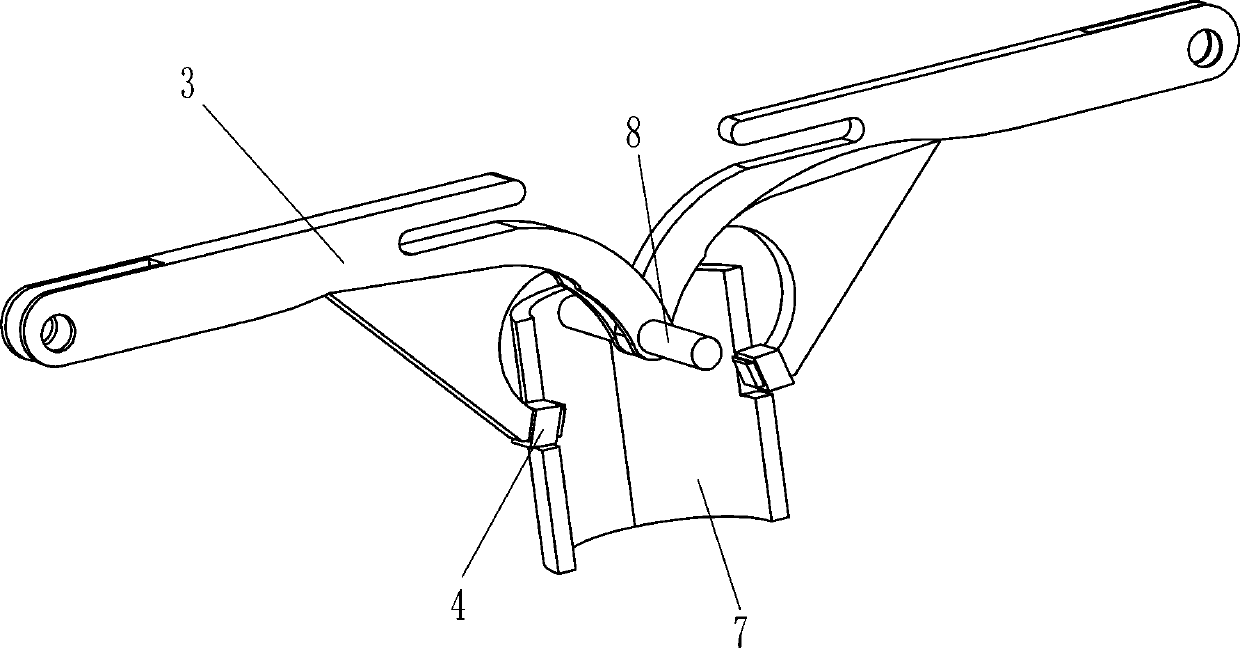

[0029] A double-headed corkscrew, such as Figure 1-5 As shown, the clamping mechanism 4 includes a mounting sleeve 41, a spring 42 and a clamping head 43. The left and right sides of the bottom of the double-headed swing rod 3 are provided with a mounting sleeve 41. The inner wall of the mounting sleeve 41 is provided with a spring 42, and the ends of the spring 42 are connected The clamping head 43 is slidably connected to the mounting sleeve 41 .

[0030] When the clamping head 43 touches the bottle cap 2, the clamping head 43 is squeezed and the spring 42 is compressed. When the clamping head 43 reaches the bottom of the bottle cap 2, under the elastic force of the spring 42, the clamping head 43 moves inwardly , move to the lower part of the bottle cap 2, so that the effect of clamping the bottle cap 2 can be achieved. When the outer end of the double-headed swing rod 3 swings upwards, the clamping head 43 also swings upwards, thereby simultaneously tightening the bottle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com