Method for preventing pump effect lifting of axial flow turbine by using guide vane closing rule

A guide vane closing rule, a technology for water turbines, applied in the direction of reaction engines, machines/engines, mechanical equipment, etc., can solve problems such as accidents, and achieve the effect of preventing pumping from lifting the machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

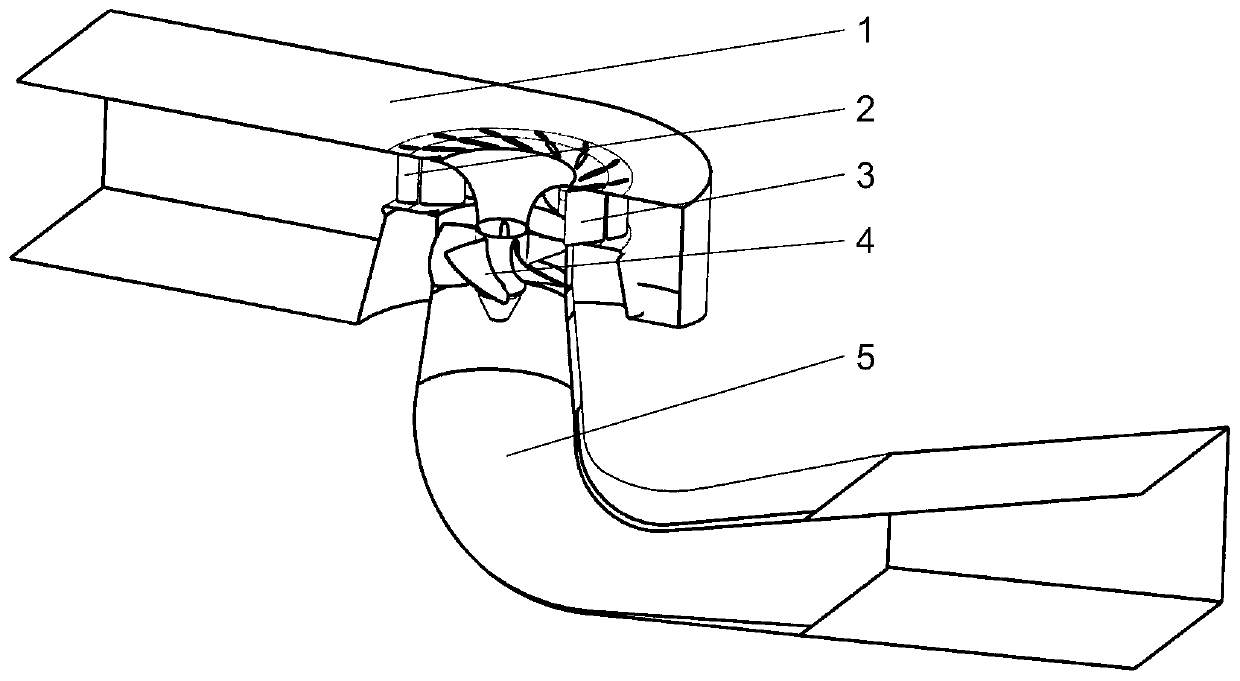

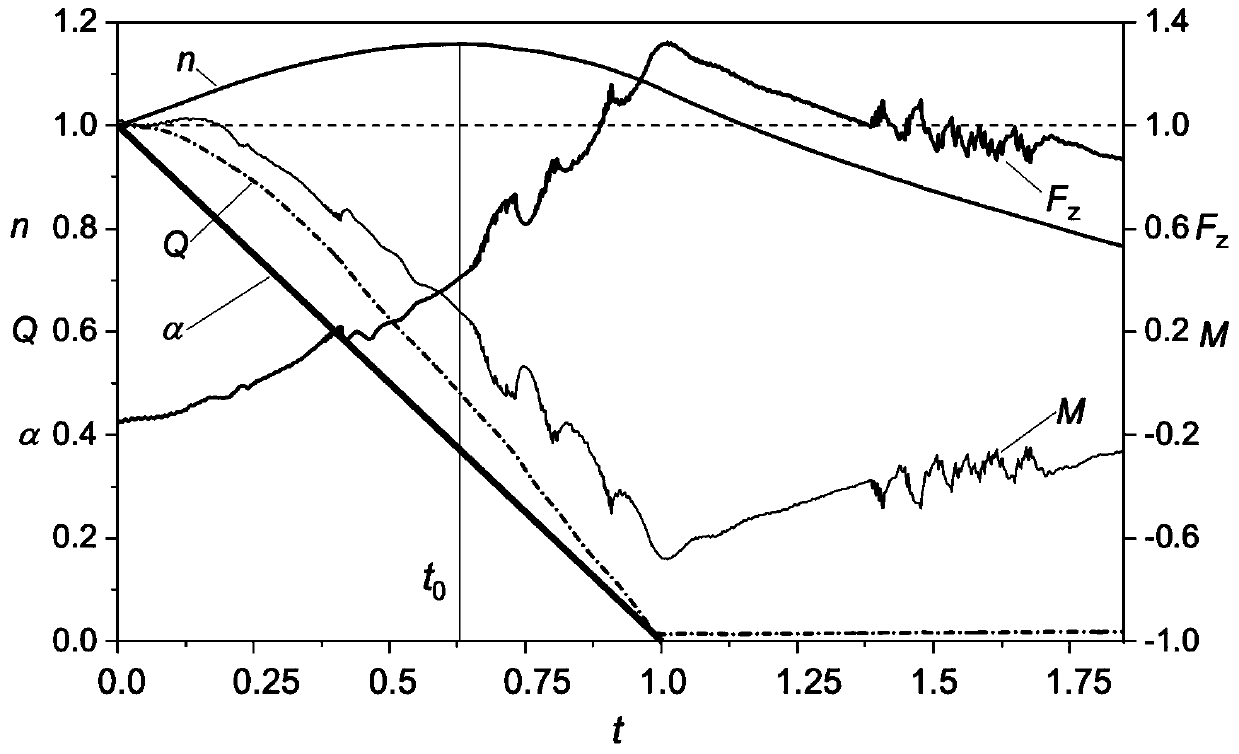

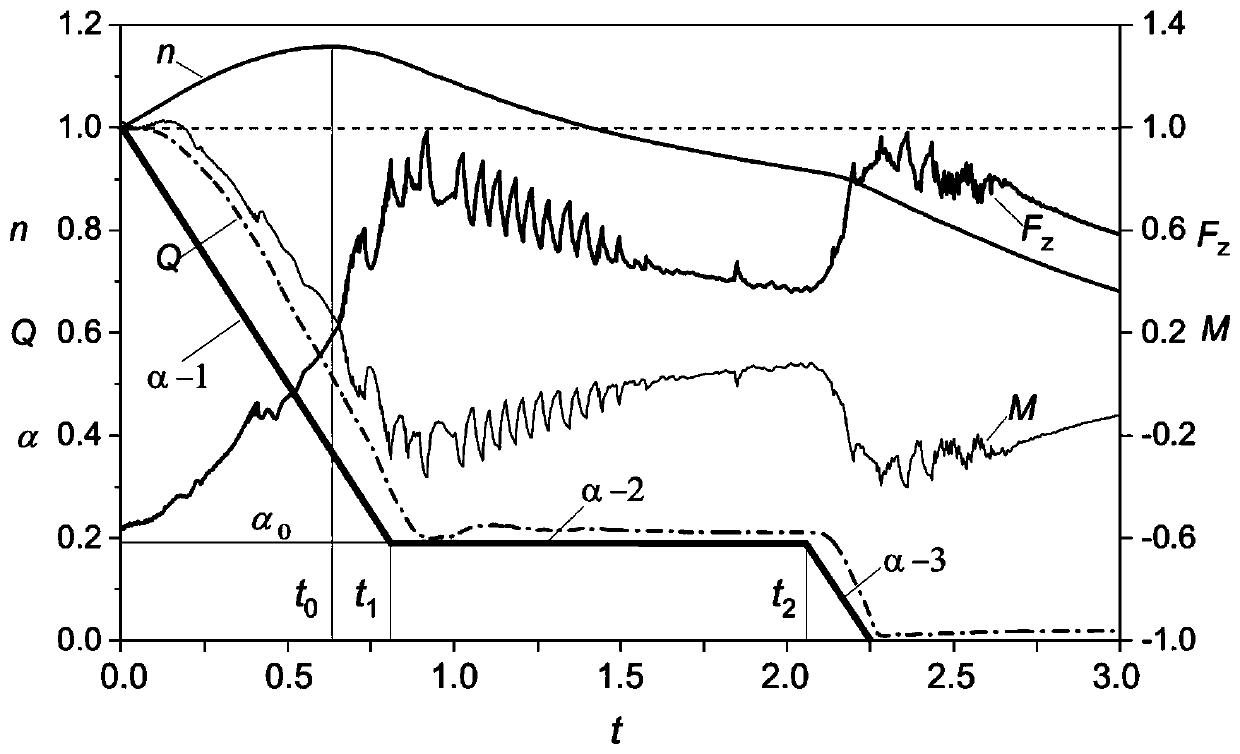

[0029] A method for preventing axial-flow turbine pump effect lift-up by using the guide vane closing rule. The entire closing process of the guide vane from the initial closing to the complete closing when the axial-flow turbine is shedding load is divided into three time periods. The opening of the middle section keeps decreasing, that is, the guide vane has a pause during the whole closing process, and the working point of the turbine is in the braking zone under the opening of the guide vane during the stop. During the pause period, the braking effect will be used to While the speed is reduced, a certain flow range is maintained, so as to avoid the occurrence of high speed and low flow at the same time, and prevent the pump effect from lifting the machine. This method does not require additional investment, and only needs to modify the governor of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com