Automatic cutting equipment for vehicle axle brake shoe

A technology for cutting equipment and brake shoes, applied in turning equipment, turning equipment, metal processing equipment, etc., can solve the uncertainty of the quality of the brake assembly, the uncertainty of the braking performance of the axle, and the quality is difficult to obtain effective. control issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

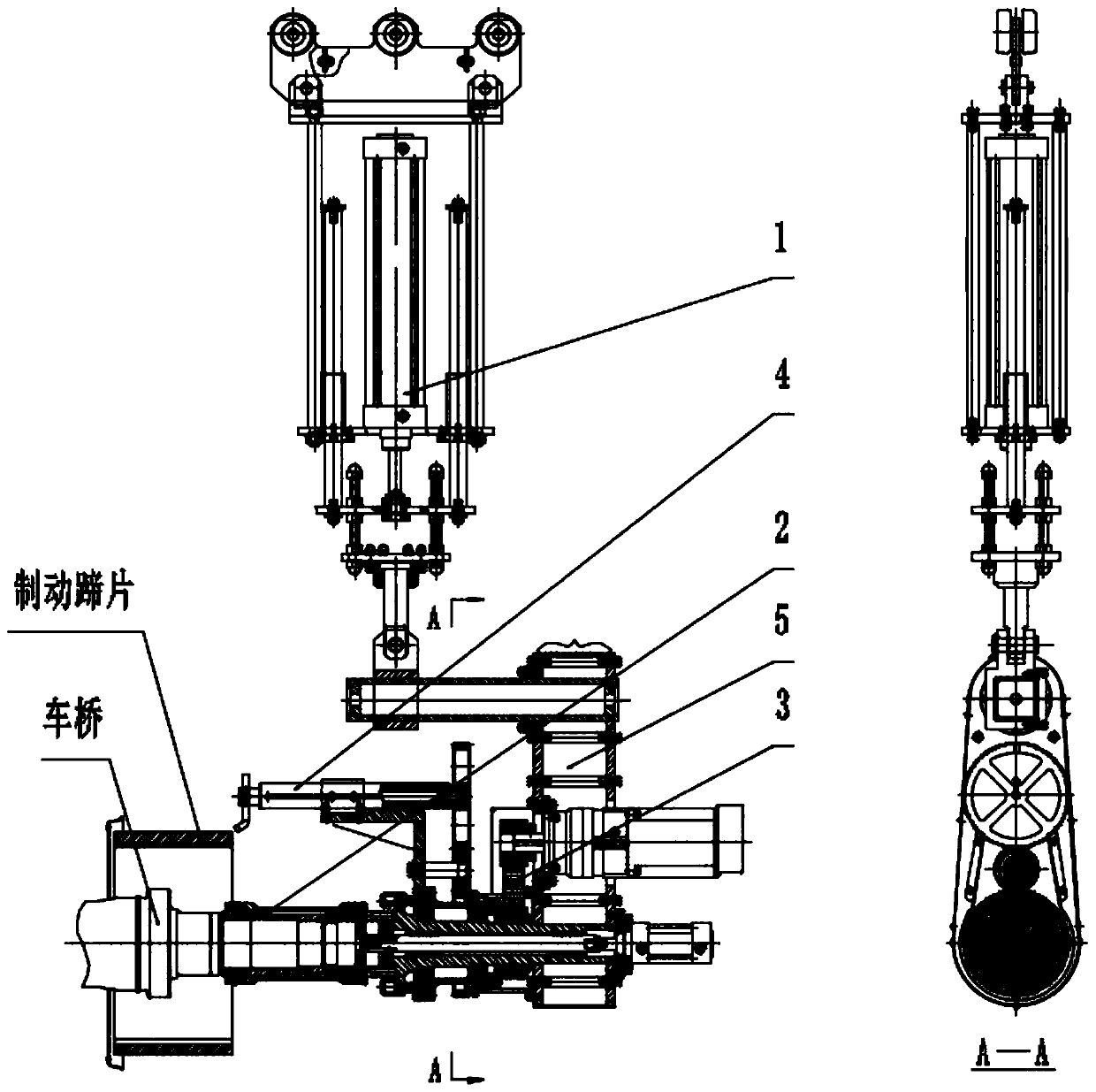

[0034] like Figures 1 to 5 As shown, a device that can realize automatic cutting and trimming of axle brake shoes.

[0035] The automatic cutting equipment for axle brake shoes includes equipment adjustment mechanism 1, centering locking mechanism 2, slewing mechanism 3, turning tool feeding mechanism 4 and equipment frame 5;

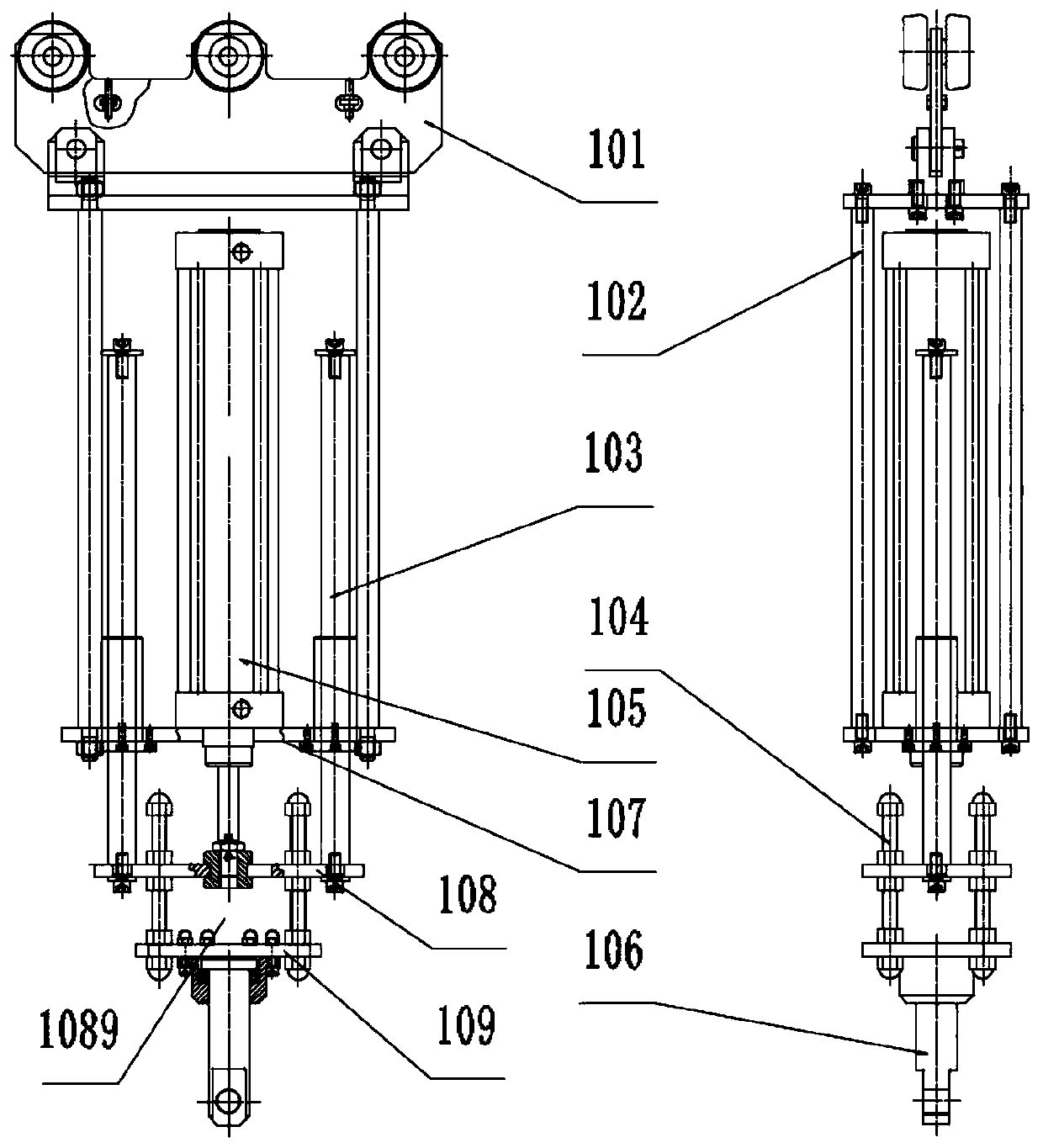

[0036] The equipment adjustment mechanism 1 is used to suspend the equipment and provide horizontal and vertical displacements for the equipment, and the connecting boom 106 of the equipment adjustment mechanism 1 is connected to the equipment frame 5;

[0037] The equipment frame 5 is fixedly connected to the equipment adjustment mechanism 1, and carries a centering locking mechanism 2 and a slewing mechanism 3;

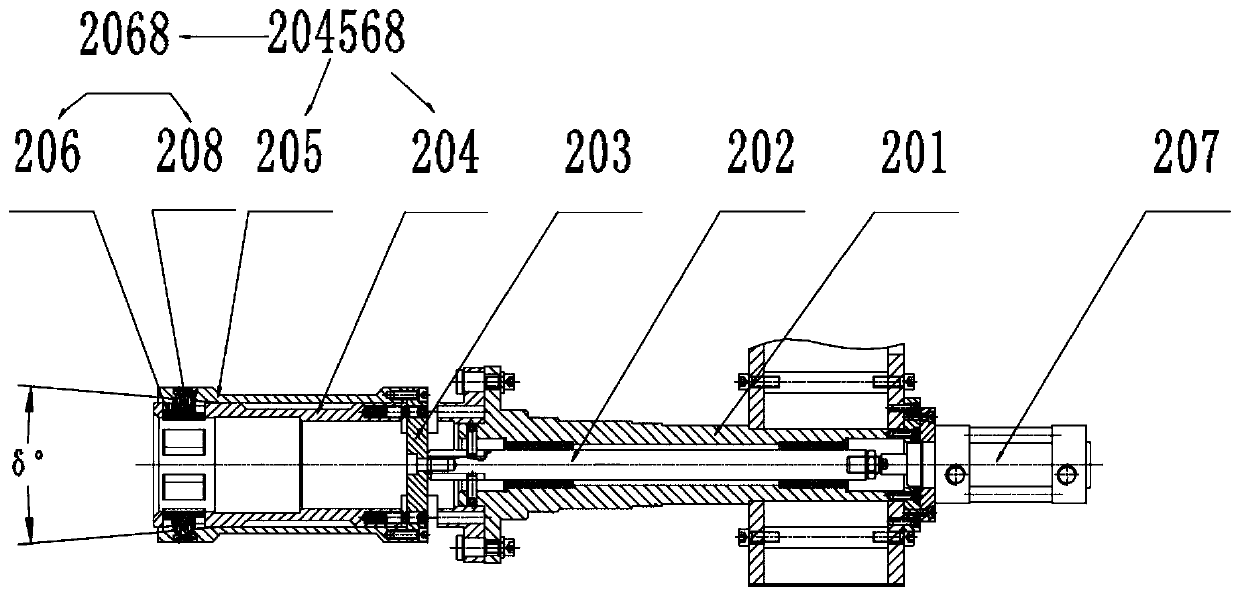

[0038] The centering locking mechanism 2 runs through the equipment frame and is fixed on the equipment frame 5, and the centering locking mechanism 2 is used to cooperate with the axle shaft to lock the axle shaft;

[0039]The slewing mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com