Steering system and crane

A steering system and auxiliary steering technology, applied in cranes, transportation and packaging, etc., can solve problems affecting reliability, etc., and achieve the effects of prolonging service life, avoiding no-load idling, reducing vibration and abnormal noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

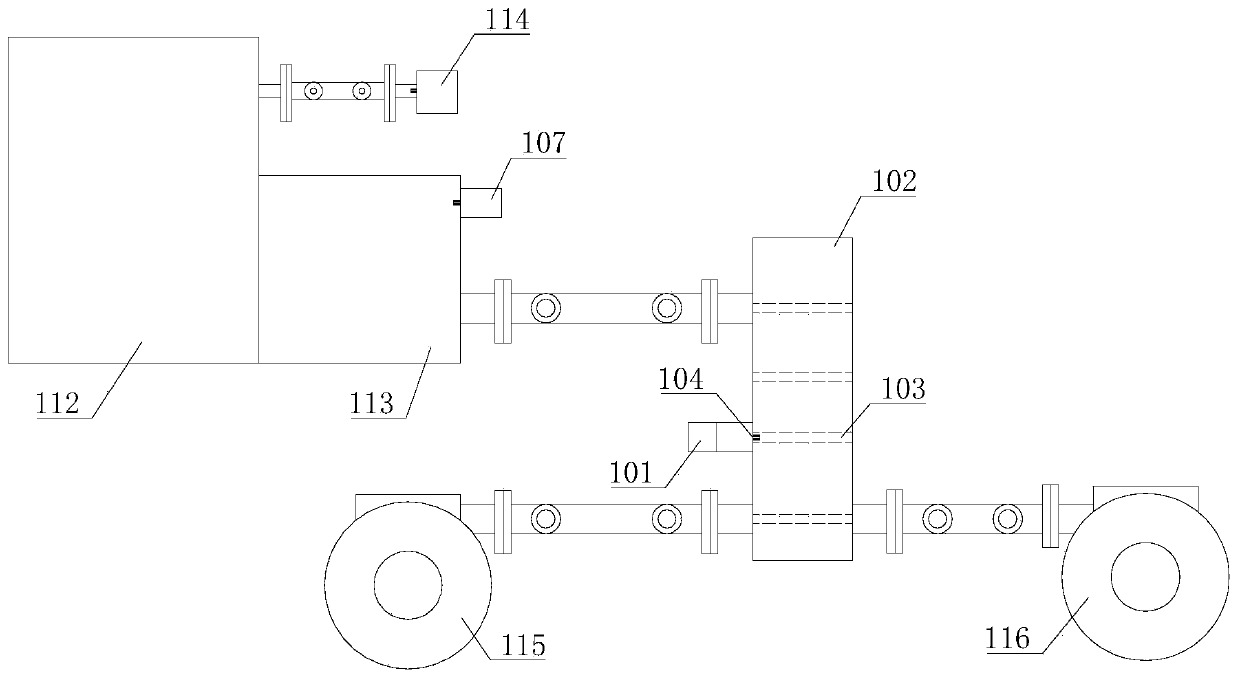

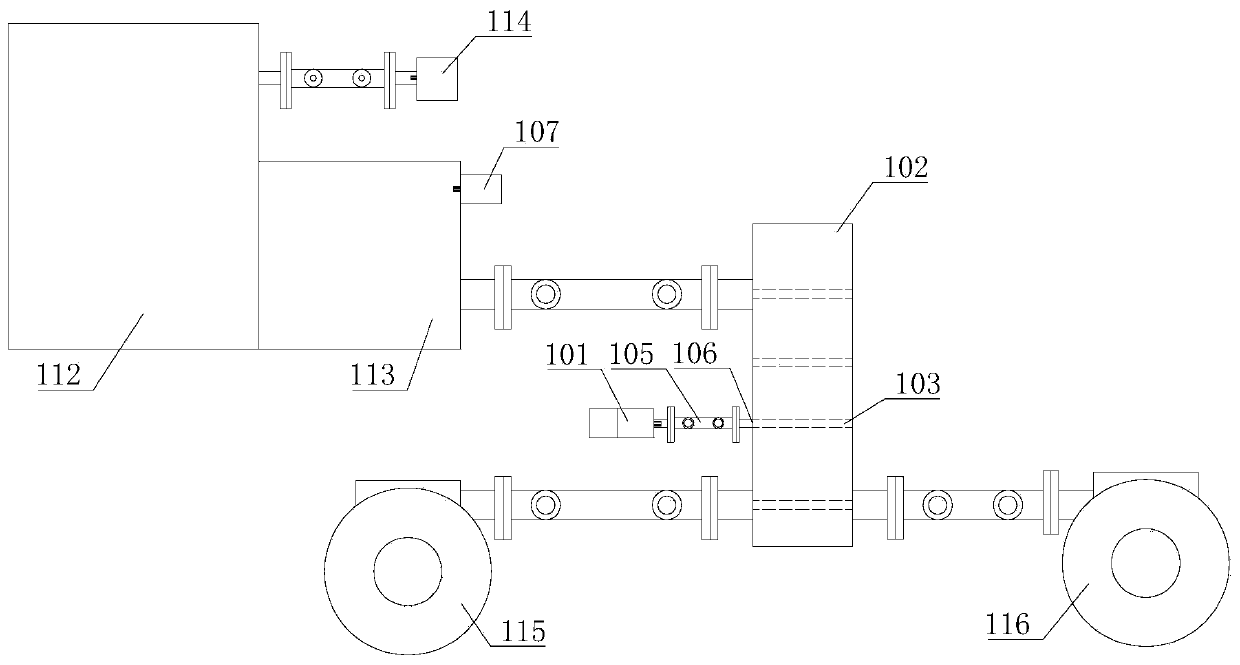

[0034] see Figure 1 to Figure 4 As shown, a steering system provided by the present application includes an auxiliary steering pump 101 and a transfer case 102 ; the transfer case 102 includes a first intermediate shaft 103 , and the input end of the auxiliary steering pump 101 is connected to the first intermediate shaft 103 .

[0035] Specifically, for the chassis of a multi-axle single-engine crane, the main steering pump 114 is installed on the engine 112, and the input shaft of the transfer case 102 is connected to the transmission 113 through the main drive shaft, and the transfer case 102 with an intermediate shaft is generally used. Drive distribution. The input shaft of the transfer case 102 can transmit driving force to the output shaft through the intermediate shaft, and the output shaft is connected to the front axle 115 and the rear axle 116 of the vehicle body through the main drive shaft. When the crane is performing in situ hoisting operations, at this time, ...

Embodiment 2

[0045] The steering system in the second embodiment is an improvement on the basis of the above embodiment. The technical content disclosed in the above embodiment will not be described repeatedly, and the content disclosed in the above embodiment also belongs to the content disclosed in the second embodiment.

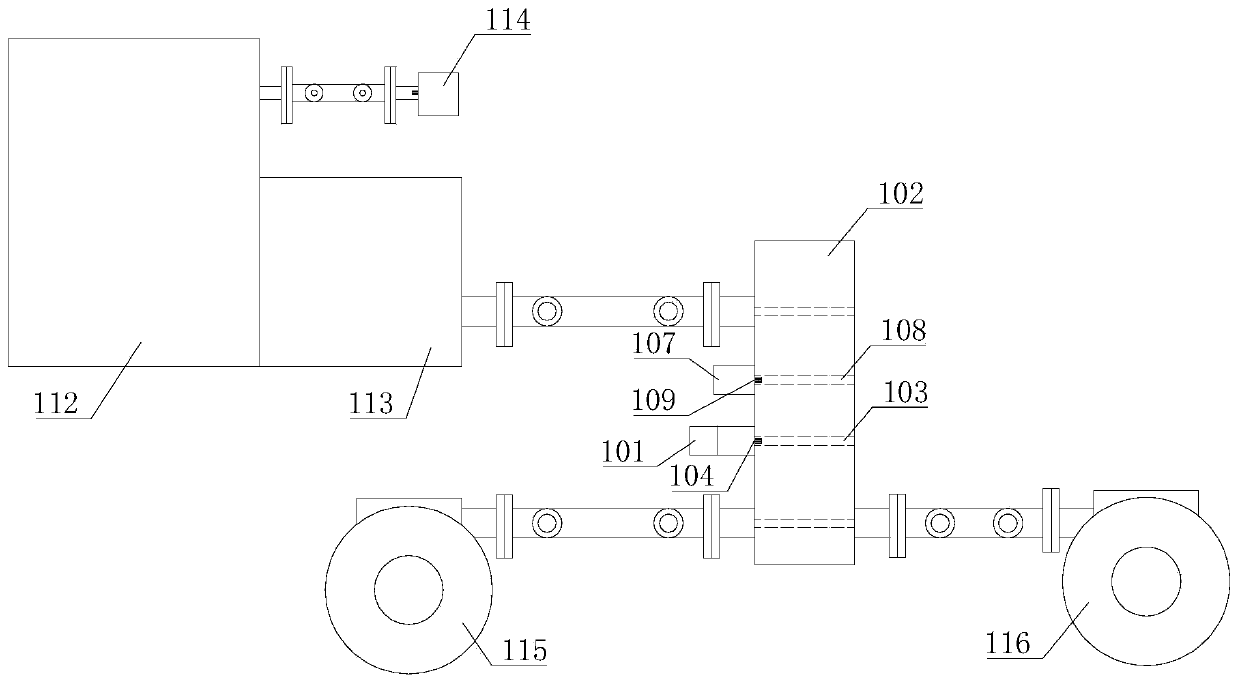

[0046] see Figure 3 to Figure 4 As shown, in an optional solution of this embodiment, the steering system further includes an emergency steering pump 107; the transfer case 102 further includes a second intermediate shaft 108, and the input end of the emergency steering pump 107 is connected to the second intermediate shaft 108.

[0047] When the main steering oil pump of the equipment fails, it is necessary to activate the emergency steering function, that is, to turn on the emergency steering pump 107 . In the prior art, the emergency steering pump 107 is generally installed on the transmission 113, and the transmission 113 needs to be equipped with a power take-off...

Embodiment 3

[0055] Embodiment 3 of the present application provides a crane, which includes the steering system of any one of the above embodiments, and thus has all the beneficial technical effects of the steering system of any one of the above embodiments, which will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com