A variable camber wing based on composite material corrugated sheet flexible skin

A composite material and plate flexibility technology, applied in the directions of wings, wing adjustment, aircraft parts, etc., can solve the problems of small out-of-plane stiffness and damage to the aerodynamic shape of the wing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and implementation examples.

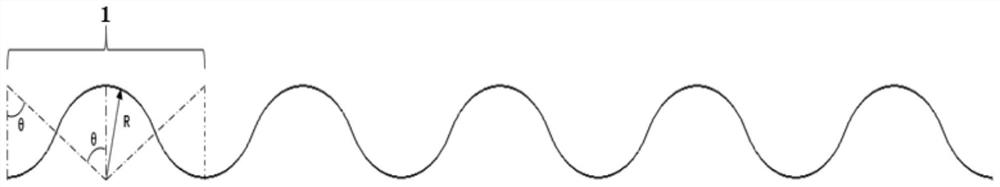

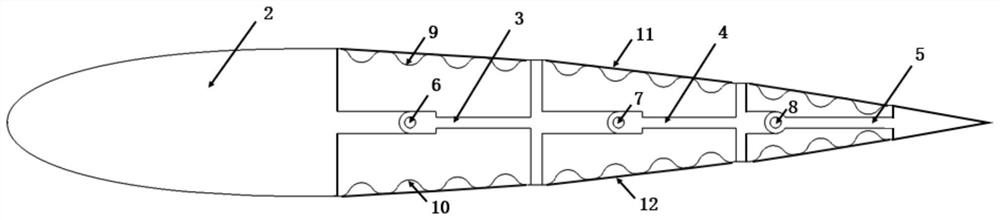

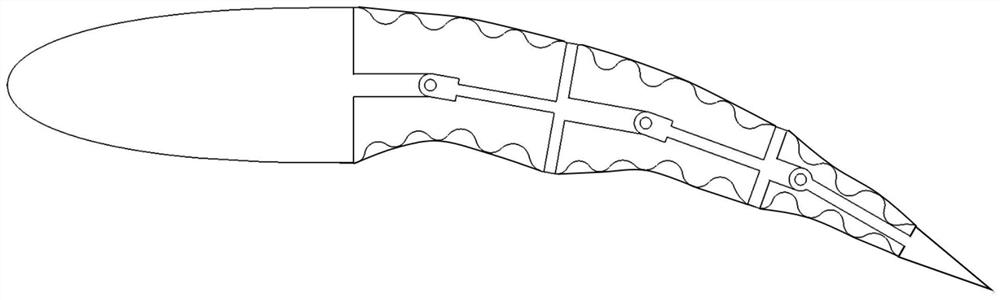

[0015] The invention is a variant airfoil based on the flexible skin of corrugated board of composite material. Composite corrugated sheet flexible skin (such as figure 1 shown) is composed of continuous corrugated units connected smoothly, the central angle of each corrugated unit is θ, and the corrugated radius is R. Composite material corrugated plates have tensile and bending deformation capabilities in the corrugated direction, and in the direction perpendicular to the corrugated direction has greater rigidity. Among them, the composite material corrugated board is a unidirectional belt laminated corrugated board made of carbon fiber, glass fiber, Kevlar fiber and boron fiber, and a woven material corrugated board made of carbon fiber, glass fiber, Kevlar fiber and boron fiber. Variant wing structures (such as figure 2 shown) is com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com