Magnetically-attracted type quickly-mounted section steel fitting

A technology of magnetic suction type and section steel, which is applied in the direction of connecting components, fixing devices, rods, etc., can solve the problems of inconvenient installation, inaccurate positioning, inconvenient use, etc., and achieve the effect of improving the quality of fixing and improving the efficiency of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

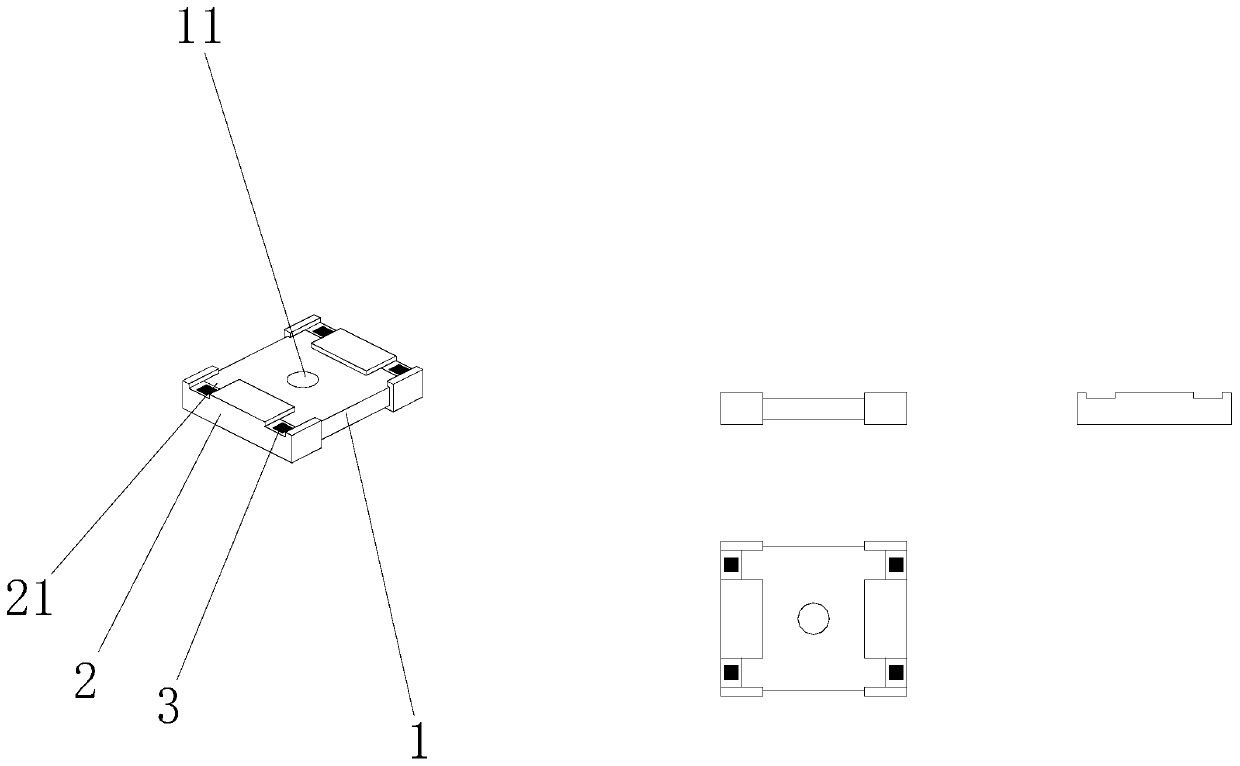

[0023] refer to figure 1 , the present invention is a magnetic fast-installation steel fitting, comprising a steel fitting body 1, an end cover 2, and a magnet 3. There are several fixing through holes 11 that can be used to cooperate with the fixing bolts. Each end of the shaped steel fitting body 1 is provided with an end cover 2, and the described end cap 2 is fixedly connected with the shaped steel fitting body 1. One side of the end cover 2 is provided with an end cover positioning chute 21 that can cooperate with the profiled steel curling, and the described end cover positioning chute 21 is provided with a magnet 3 for adsorption with the profiled steel.

Embodiment 2

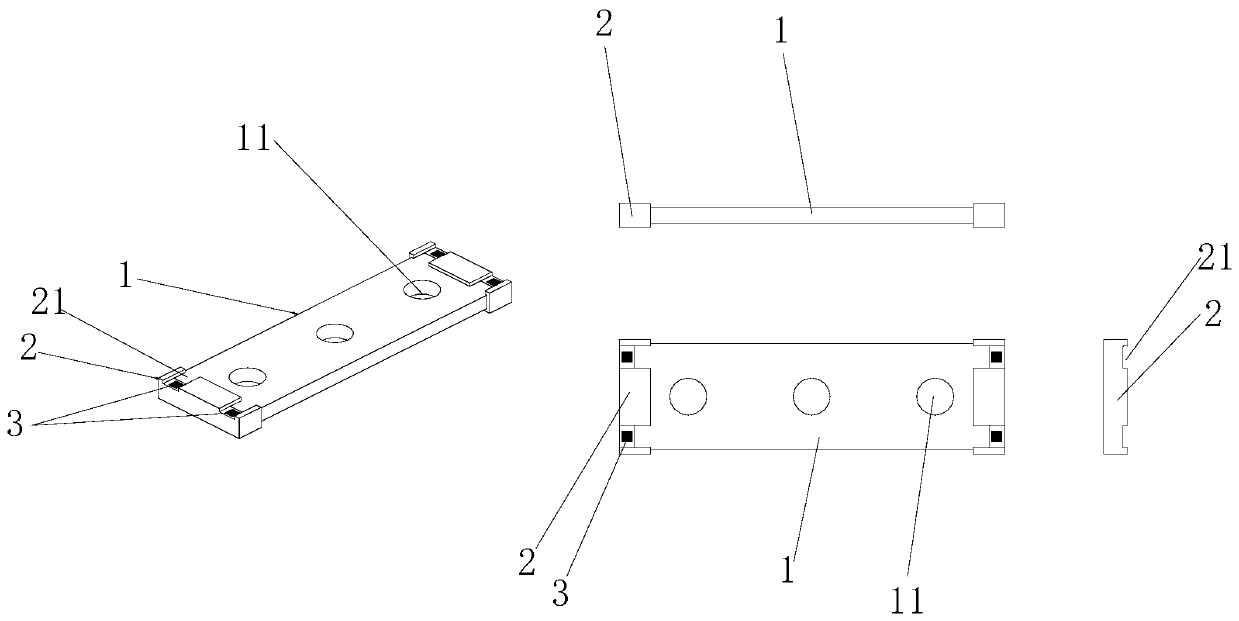

[0025] refer to figure 2 , the present invention is a magnetic fast-installation steel fitting, comprising a steel fitting body 1, an end cover 2, and a magnet 3. There are several fixing through holes 11 that can be used to cooperate with the fixing bolts. Each end of the shaped steel fitting body 1 is provided with an end cover 2, and the described end cap 2 is fixedly connected with the shaped steel fitting body 1. One side of the end cover 2 is provided with an end cover positioning chute 21 that can be matched with the profile steel curling, and the described end cover positioning chute 21 is provided with a magnet 3 for adsorption with the profile steel, and the profile steel fitting body 1 It is a straight shape, the end caps 2 are arranged symmetrically at both ends of the steel fitting body 1, and the magnets 3 are arranged in the positioning chute 21 of the end caps.

Embodiment 3

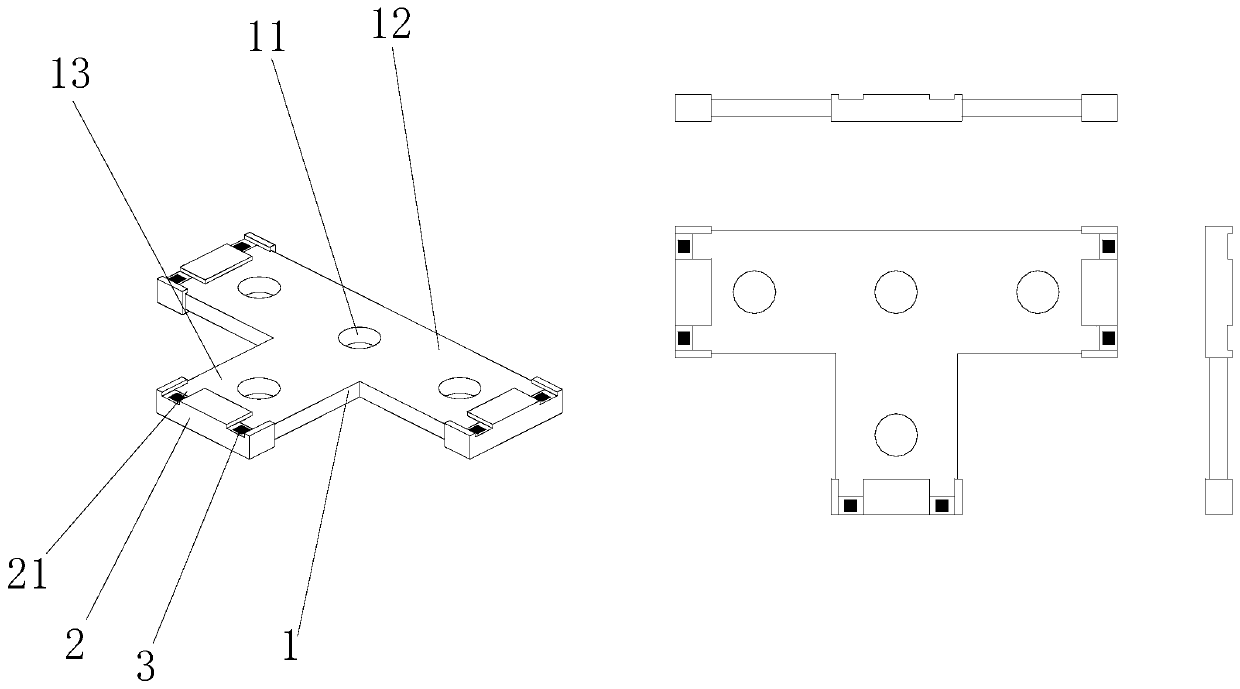

[0027] refer to image 3 , the present invention is a magnetic fast-installation steel fitting, comprising a steel fitting body 1, an end cover 2, and a magnet 3. There are several fixing through holes 11 that can be used to cooperate with the fixing bolts. Each end of the shaped steel fitting body 1 is provided with an end cover 2, and the described end cap 2 is fixedly connected with the shaped steel fitting body 1. One side of the end cover 2 is provided with an end cover positioning chute 21 that can be matched with the profile steel curling, and the described end cover positioning chute 21 is provided with a magnet 3 for adsorption with the profile steel, and the profile steel fitting body 1 It is T-shaped, and the section steel fitting body 1 includes a T-shaped horizontal plate 12 and a T-shaped lower plate 13. The middle section of one side of the T-shaped horizontal plate 12 is vertically provided with a T-shaped lower plate 13. Both ends of the horizontal plate 12 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com