Camera module and electronic equipment

A camera module and electronic equipment technology, applied in the field of electronics, can solve the problem that the functional requirements of the breathing lamp and the screen ratio requirements cannot be taken into account, affecting the user experience, etc., so as to achieve the consideration of the amount of light output, avoid the weakening of the light, and achieve high-quality imaging quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

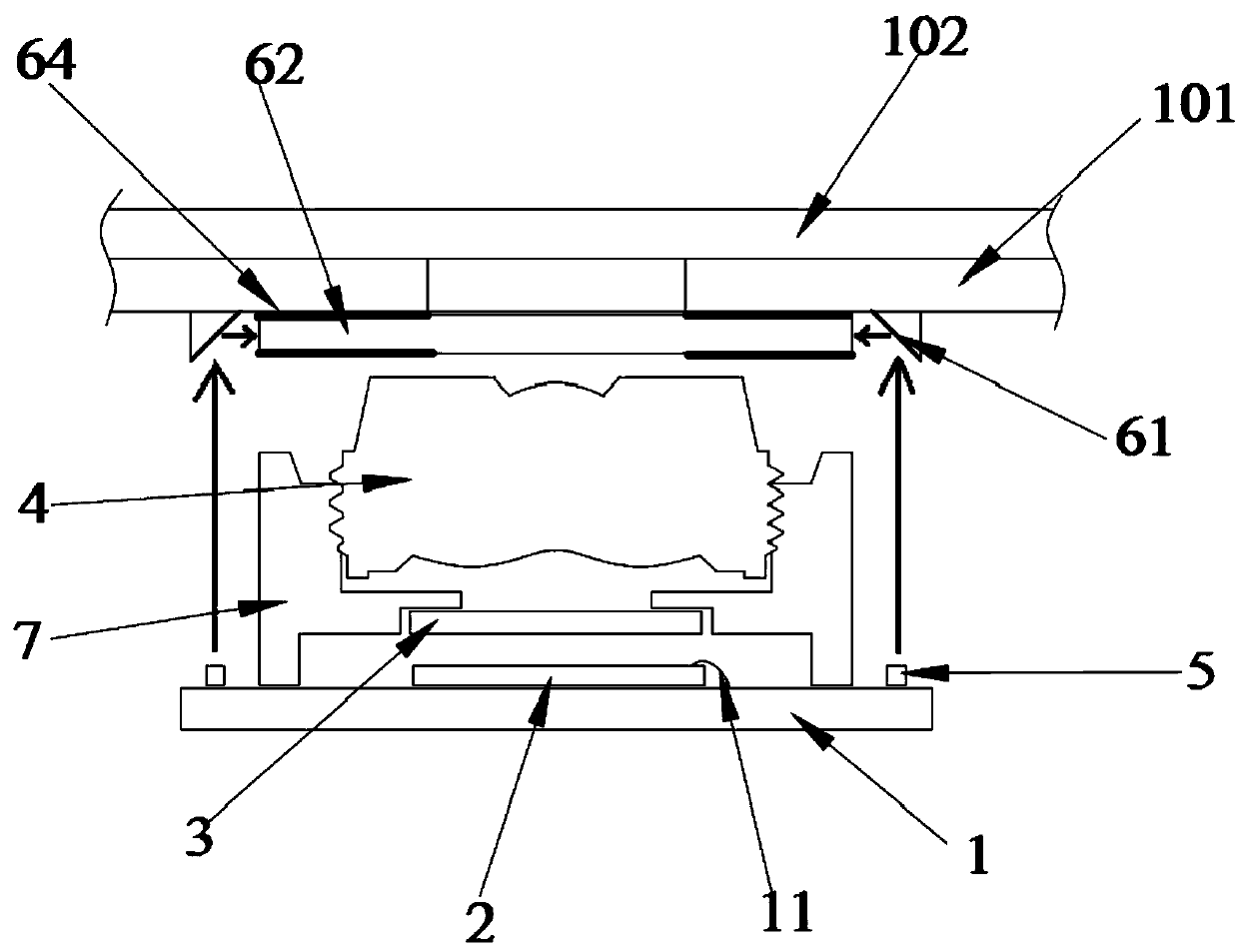

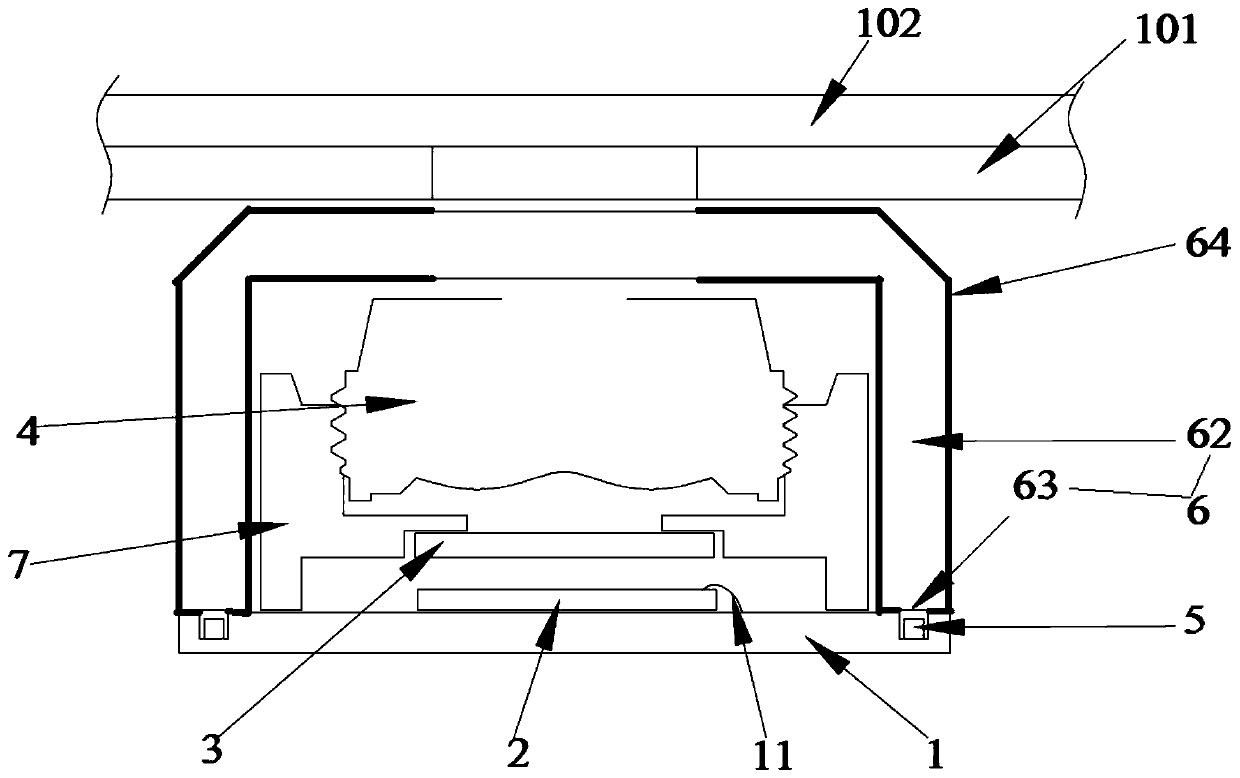

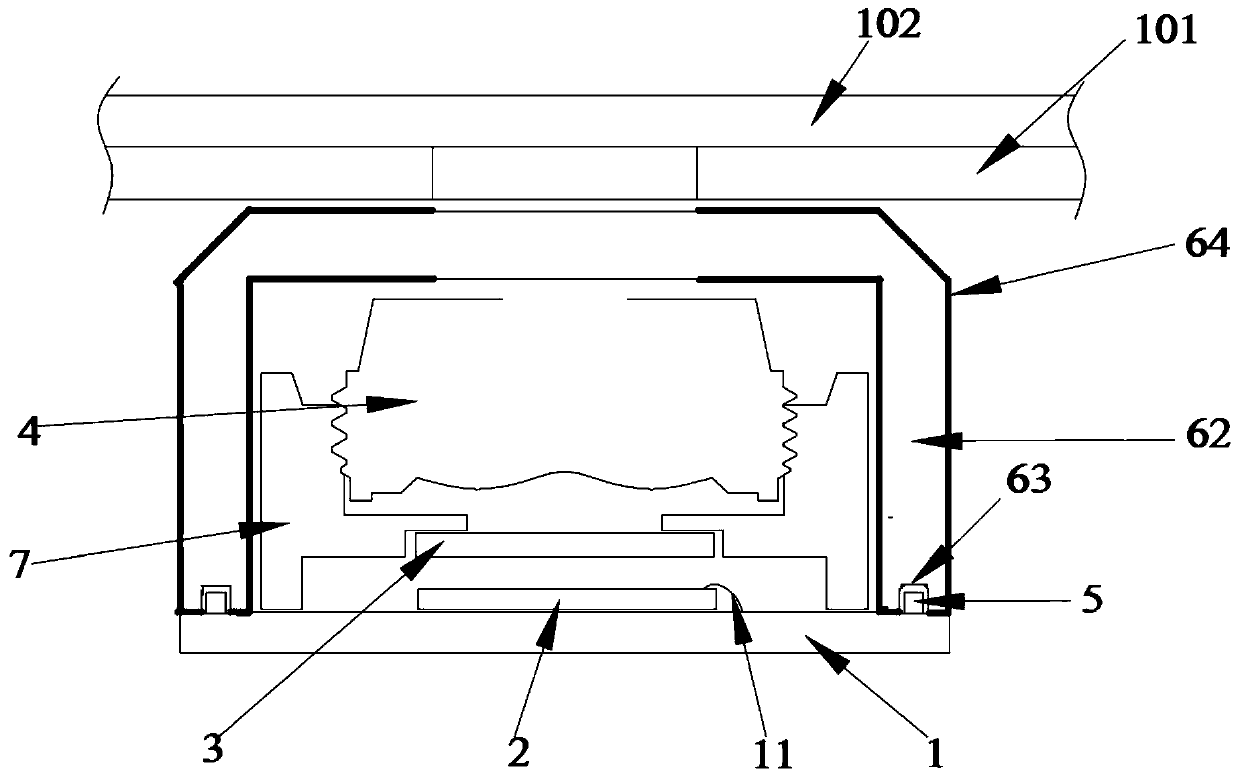

[0030] In this embodiment, a camera module is provided, such as Figure 1-5 shown, including:

[0031] An imaging section and a light emitting section, wherein the imaging section includes a circuit substrate 1, a photosensitive element 2 and a lens 4, and the light emitting section includes a light emitting element 5 and a light guide structure 6;

[0032] Wherein, the light-emitting element 5 is fixed on the outer surface of the imaging part, and the light emitted by the light-emitting element 5 is guided by the light guide structure, and is emitted out of the camera module from the direction facing the front of the lens 4, so as to realize the connection with the camera module. The optical path of the photosensitive element 2 to obtain light basically overlaps, so that after the camera module is installed in the electronic device, the light emitting element 5 and the photosensitive element 2 can emit and obtain light through the same transparent hole. In addition, there is...

Embodiment 2

[0063] like Image 6 As shown, this embodiment provides an electronic device, including the camera module 601 described in the first embodiment.

[0064] In a specific implementation process, the electronic device may be a mobile phone, a tablet computer, a tester, or a smart watch, etc., which are not limited here and will not be listed one by one.

[0065] In a specific implementation process, the electronic device may include a screen 101, the camera module 601 is located under the screen 101, and the outer surface of the screen 101 may also be provided with a protective layer 102 (for example, a glass layer). The light emitting element 5 in the electronic device may be a light source for realizing the function of a breathing light. Through the built-in camera module 601 provided by Embodiment 1, which has both light-emitting element 5 and photosensitive element 2, the breathing light function or other light-emitting functions of the electronic device can share the same tr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap