Split type field metallographic microscope

A metallurgical microscope, split-type technology, applied in microscopes, material analysis, material analysis through optical means, etc., can solve the problems of unsatisfactory area clarity, misjudgment, and image quality reduction, so as to improve work efficiency and imaging Quality, reduce interference factors, improve the effect of image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

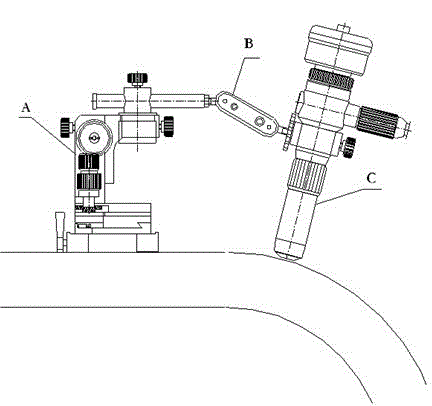

[0027] like figure 2 As shown, a split-type on-site metallographic microscope of the present invention adopts a split-type structure, including an independent microscope base A and a mirror body C with optical system components, and the microscope base A and mirror body C are detachable A steering adjustment bracket B is connected, and one end of the steering adjustment bracket B is fixed on the microscope base A of the matching on-site metallurgical microscope, and the other end is fastened to the mirror body C with an optical system. On the premise of ensuring the stability of the mirror body C, according to the detection needs, the steering adjustment bracket B is adjusted in multiple directions so that the tested surface is perpendicular to the optical system in the mirror body C, so as to obtain a relatively clear picture.

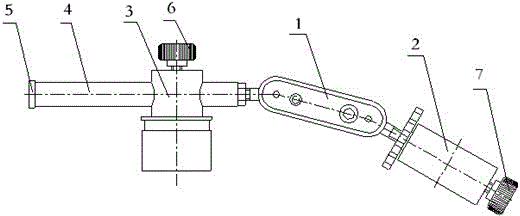

[0028] like image 3 , 4 As shown, the specific structure of the present invention includes a steering adjustment bracket B. The steering adjustme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com