An infrared control bionic laminated device

A technology of lamination and device, applied in the field of infrared regulation, can solve the problems of no natural leaf tissue structure and composition characteristics, different spectra of the same color, differences in the real characteristics of leaves, etc., so as to improve infrared transmission performance and enhance hyperspectral bionic properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

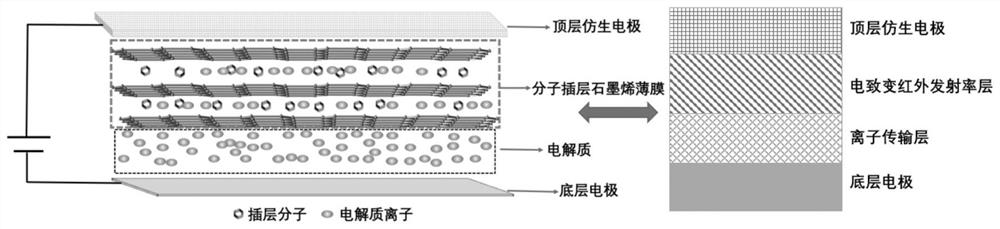

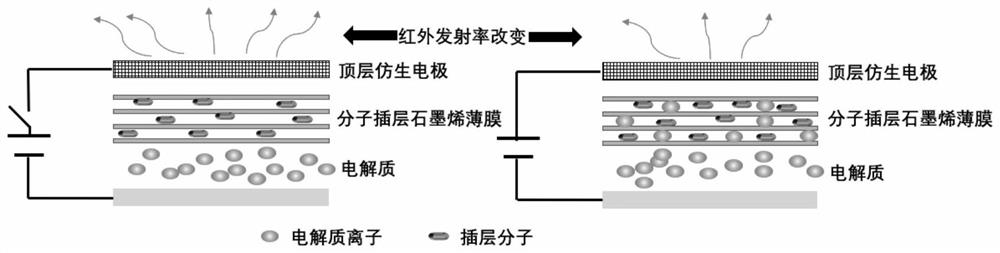

[0023] An infrared control bionic laminated device, the preparation process is as follows:

[0024] Step 1. Preparation of the top bionic electrode:

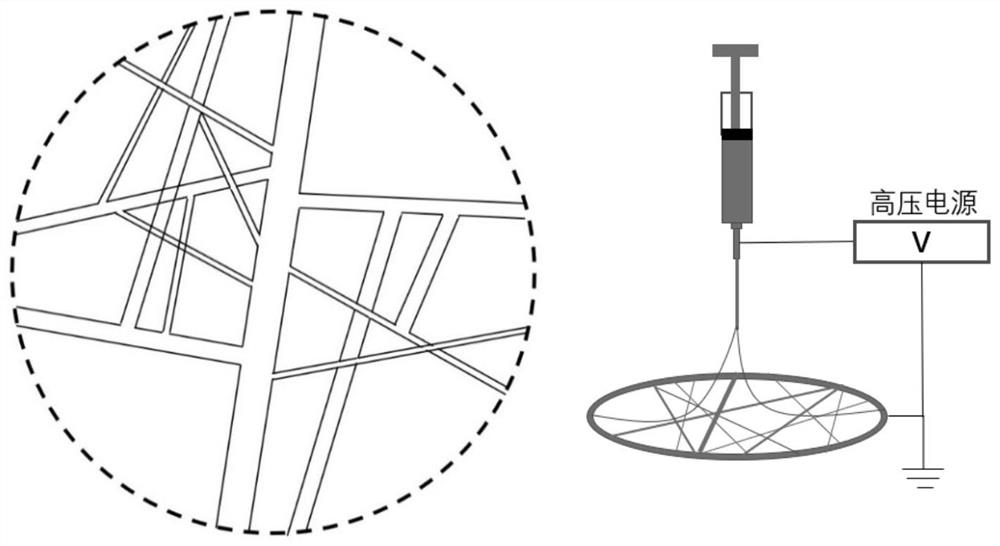

[0025] 1.1 Select polyvinylpyrrolidone as the electrode structure template, dissolve polyvinylpyrrolidone (Mr=1300000) in absolute ethanol, and prepare a precursor solution with uniform viscosity; transfer the prepared precursor solution to the spinning tube, and use electrospinning The electrode template was obtained by the method, the spinneret with a diameter of 0.25mm, the airflow pressure of 0.26MPa, the air duct width of 0.4mm, the air duct angle of 60°, and the receiving distance of 20mm were selected, and the spinning voltage (8kV, 10kV, 12kV) was adjusted to change the polymer Whip during the fiber forming process to obtain nanofibers with different diameters, and collect the polymer fibers into a copper frame vessel, so as to realize the preparation of nanofibers with diameters of 600nm, 1300nm and 2400nm in the same p...

Embodiment 2

[0035] An infrared control bionic laminated device, the preparation process is as follows:

[0036] Step 1. Preparation of the top-layer biomimetic electrode: select metal gold as the electrode material, first prepare a gold film with a thickness of 80 μm on the PET substrate by magnetron sputtering, and then spin-coat a uniform layer of gold film on the surface of the gold film to be etched. Photoresist, after soft baking, a layer of photoresist film can be formed on the surface, and then through the process of ultraviolet exposure, development, shaping and hardening, the pattern with vein structure on the mask plate can be accurately transferred to the photolithography of the metal surface Finally, use inductively coupled plasma etching method to etch and remove the part not covered by the photoresist on the gold film. After removing the photoresist, the top biomimetic electrode with leaf vein structure is obtained;

[0037] Step 2. Preparation of the electrovariable infrare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com