Mold for manufacturing bulb lamps and rapid demolding method

A technology for bulb lamps and molds, which is applied in the field of mold manufacturing, can solve problems affecting work efficiency and waste of manpower, and achieve the effect of ensuring aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

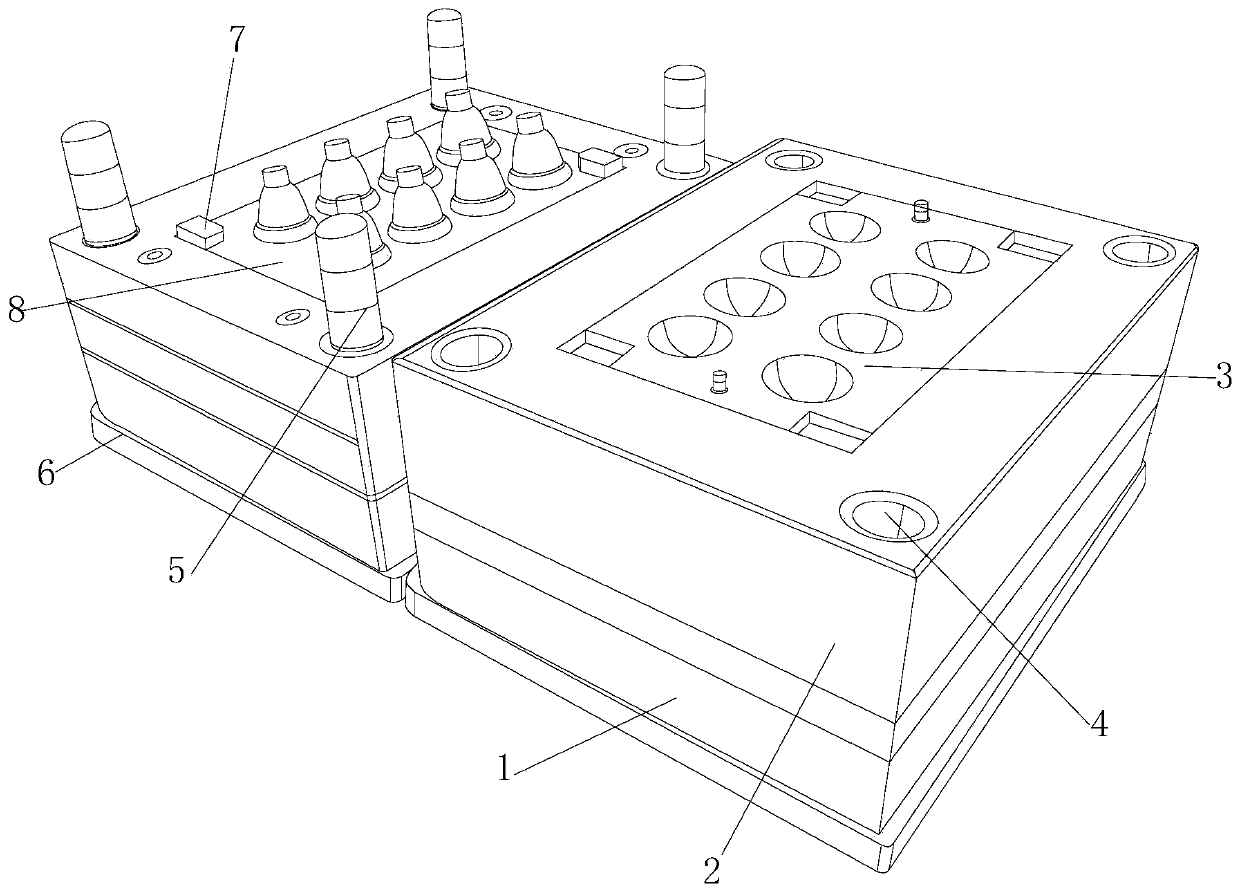

[0029] see figure 1 , a mold for manufacturing bulb lamps of the present invention and a quick demoulding method, including a base plate 1, a lower mold base 2, a forming base structure 3, a positioning hole 4, a positioning column 5, a top seat 6, a rectangular limit block 7 and The upper mold base 8 and the top of the bottom sheet 1 are integrally formed with a lower mold base 2, and the four ends of the lower mold base 2 are provided with positioning holes 4, and the inside of the positioning hole 4 is plugged with a positioning column 5, and the positioning column 5 is fixed on the top of the top base 6. end, the upper mold base 8 is embedded in the inner side of the top base 6, and the four ends of the top of the upper mold base 8 are fixed with rectangular limit blocks 7, and the inner top side of the lower mold base 2 is embedded with a forming base structure 3, through which the forming base structure 3 The product is ejected directly after molding.

[0030] see fig...

Embodiment 2

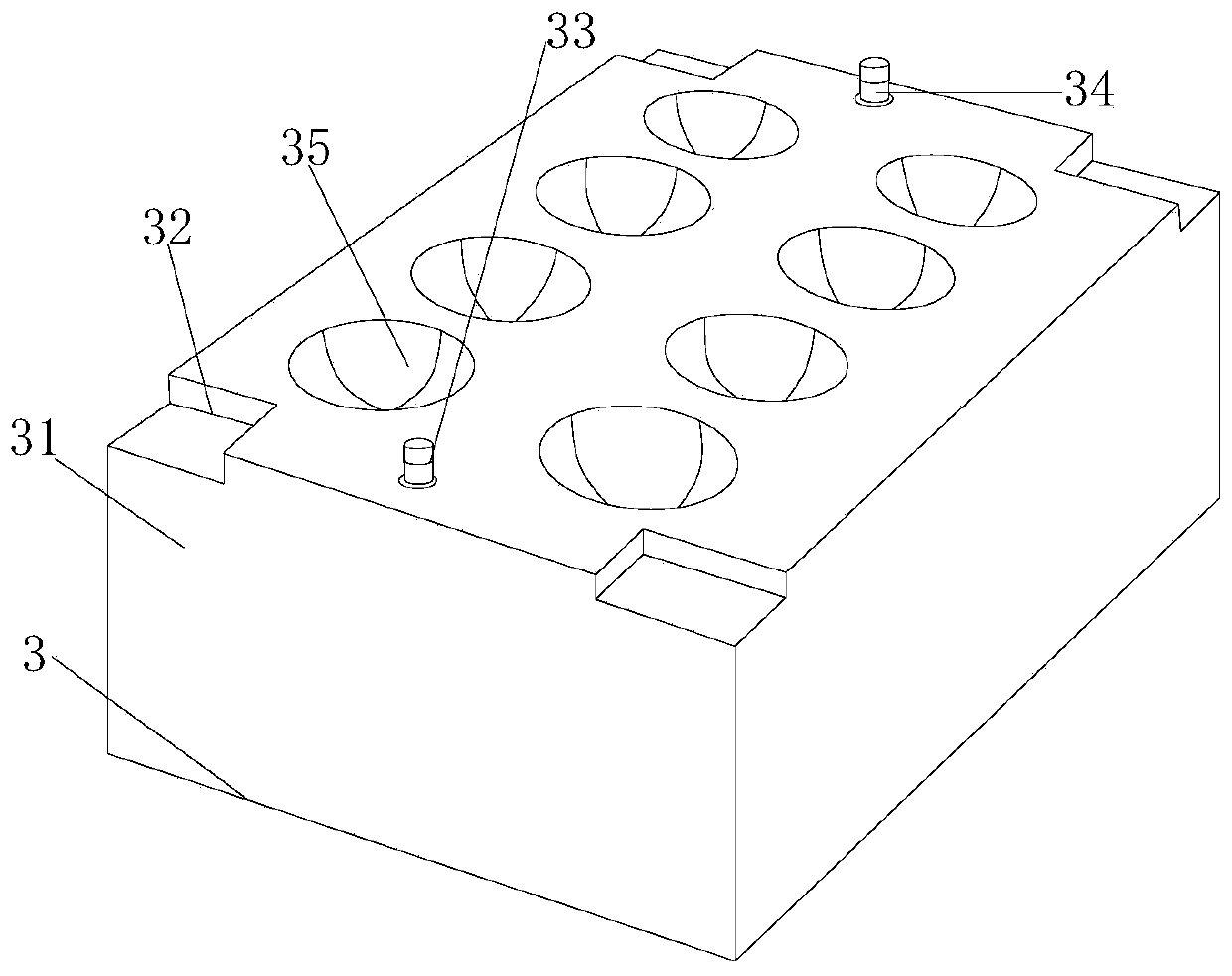

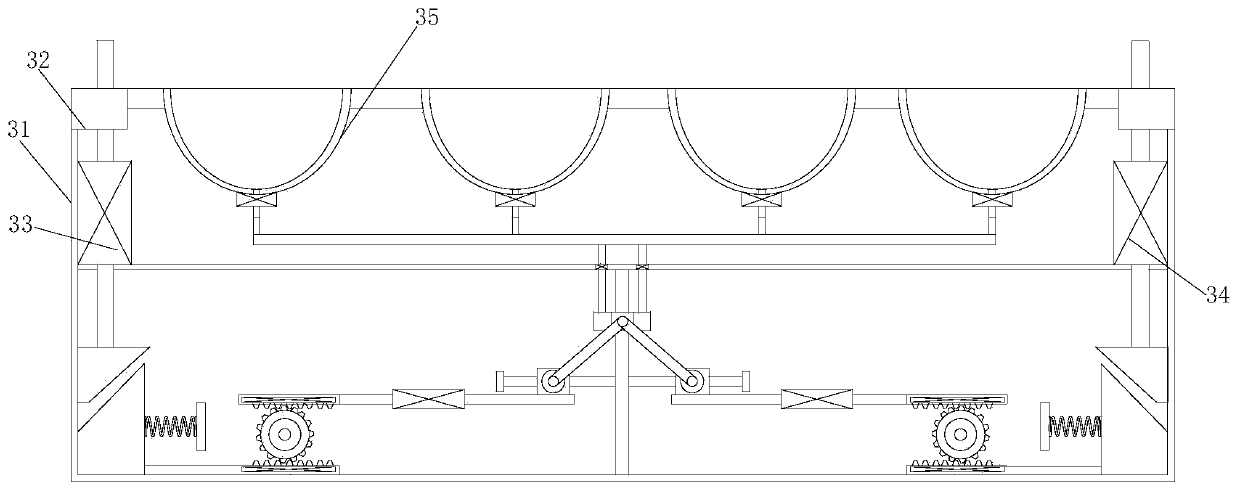

[0036] A mold for manufacturing a bulb lamp and a quick demoulding method of the present invention, the position of the limiting groove 32 corresponds to the position of the rectangular limiting block 7, and the length and width of the limiting groove 32 are greater than the length of the rectangular limiting block 7 And width 0.5cm, is conducive to limit, the structure of left strut assembly 33 and right strut assembly 34, size are all the same, and left and right strut assembly 33 and right strut assembly 34 are symmetrical left and right inside frame body 31, top A total of eight ejector rods 3374 are provided, and the eight ejector rods 3374 are respectively inserted into the inside of the forming groove 35, and the ejector rods 3374 and the forming groove 35 are seamlessly matched to ensure the aesthetics of product molding.

[0037] The present invention provides a mold for manufacturing bulb lamps and a rapid demoulding method through improvement, and its working princip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com