Electromagnetically-driven spin lock type plate connecting device and method

An electromagnetic drive, plate connection technology, applied in the field of plate connection, can solve problems such as plate damage and reduce connection quality, and achieve the effects of easy control, improved connection strength, and tight connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the technical problems, technical solutions and advantages to be solved by the present invention more clear, the following will be described in detail with reference to the accompanying drawings and specific embodiments.

[0043] Aiming at the problems that the connection strength of the existing traditional plate connection methods is greatly affected by the outside world and some connection methods require additional auxiliary materials, the invention provides an electromagnetically driven twist-lock type plate connection device and method.

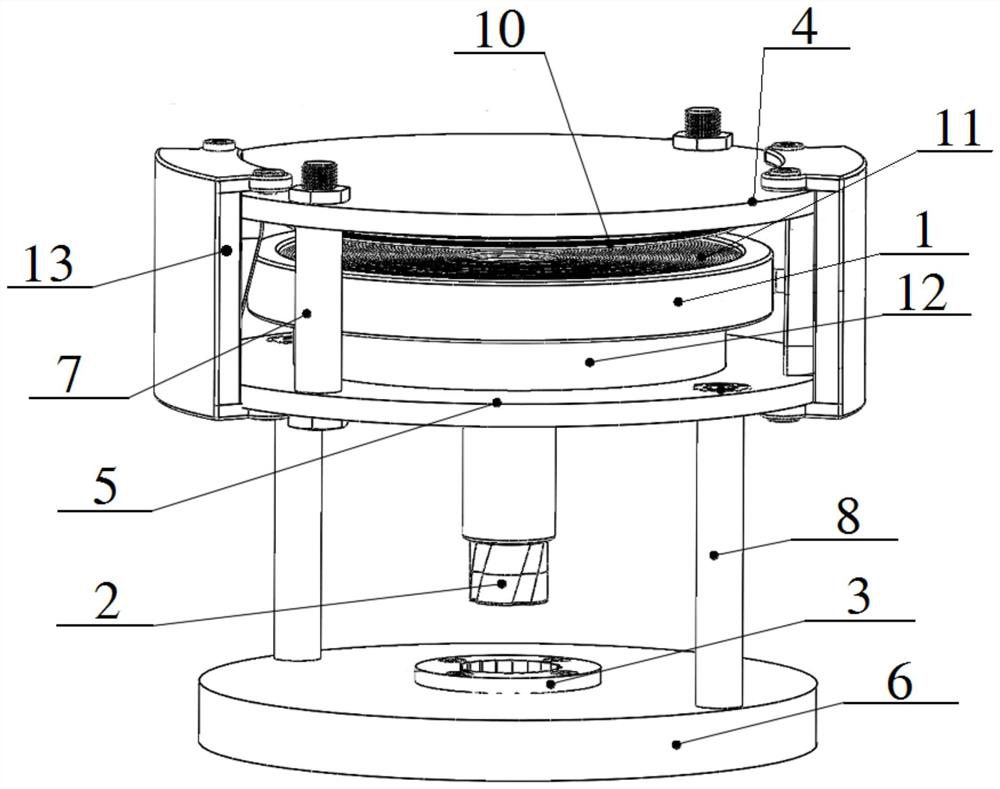

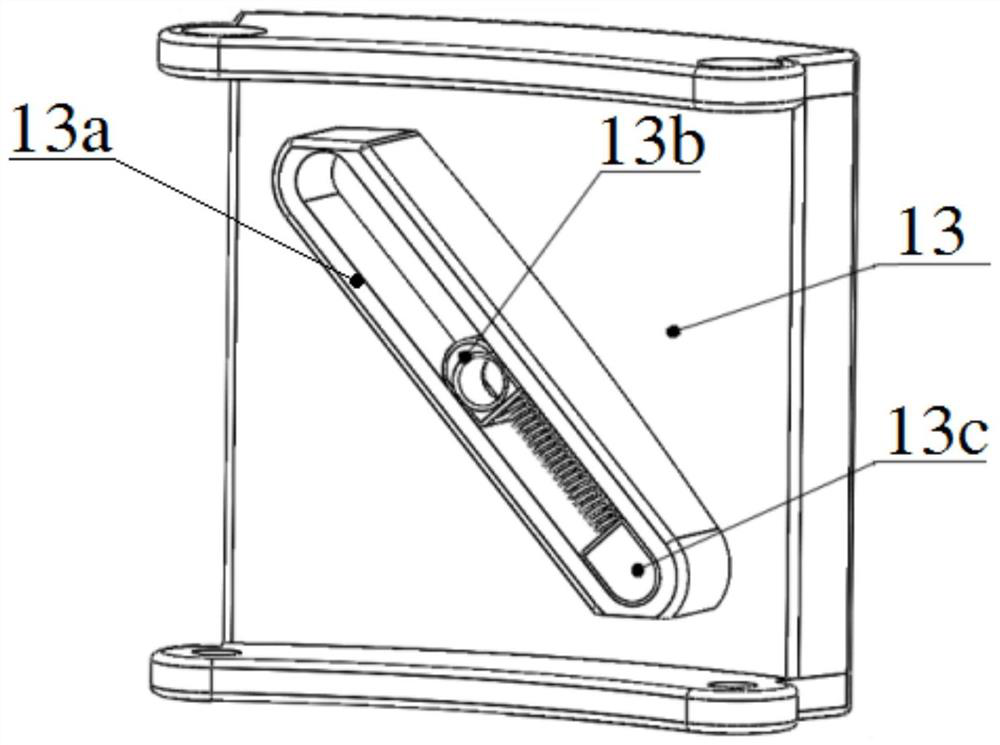

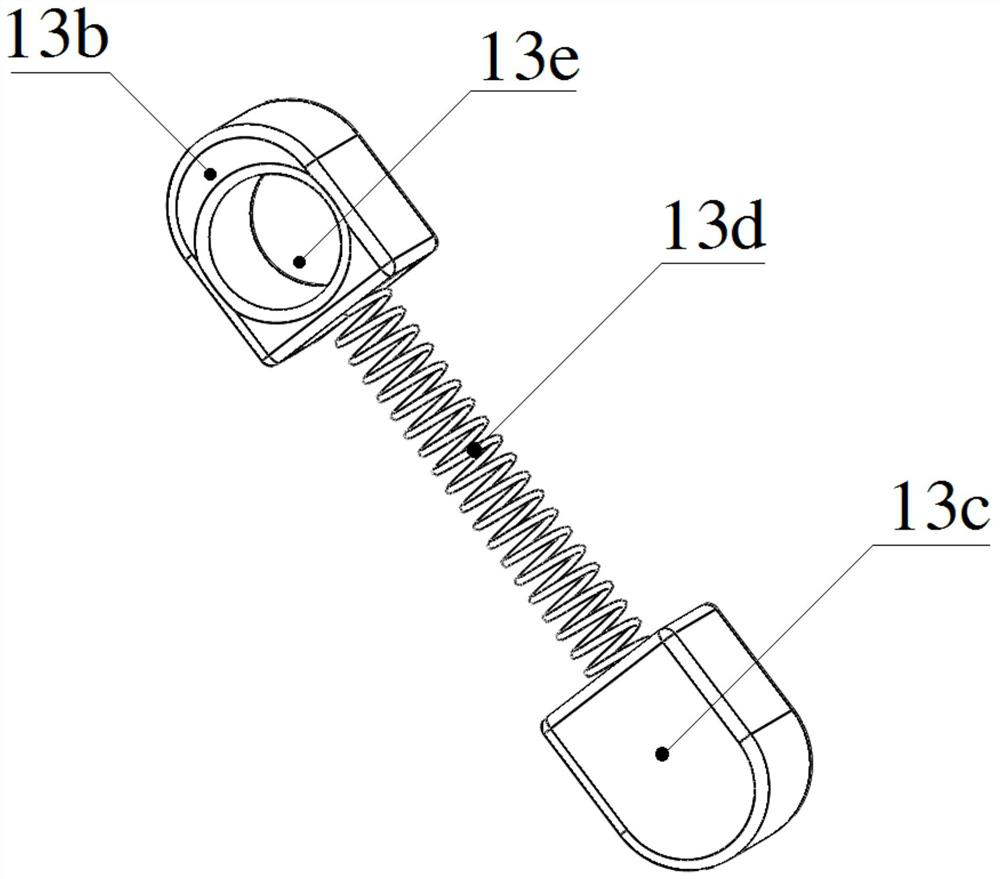

[0044] like figure 1As shown, the embodiment of the present invention provides an electromagnetically driven twist-lock type plate connecting device, including: a supporting frame, an electromagnetic driving device, an electromagnetic moving plate 1, a guide plate 13, a punching head 2 and a bottom mold 3; the The support frame includes a top support plate 4, a guide plate 5 and a bottom support plate 6. The cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com