Double-acting friction damper of railway wagon bogie

A technology for frictional vibration reduction and railway wagons, which is applied in the direction of bogies, railway car body parts, devices for lateral relative movement between the chassis and bogies, etc. The reaction force is small, and the effect of improving the anti-diamond stiffness is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The implementation of the present invention will be described in detail below in conjunction with the examples of implementation, but they do not constitute a limitation of the present invention, and are only examples. At the same time, the advantages of the present invention will become clearer and easier to understand.

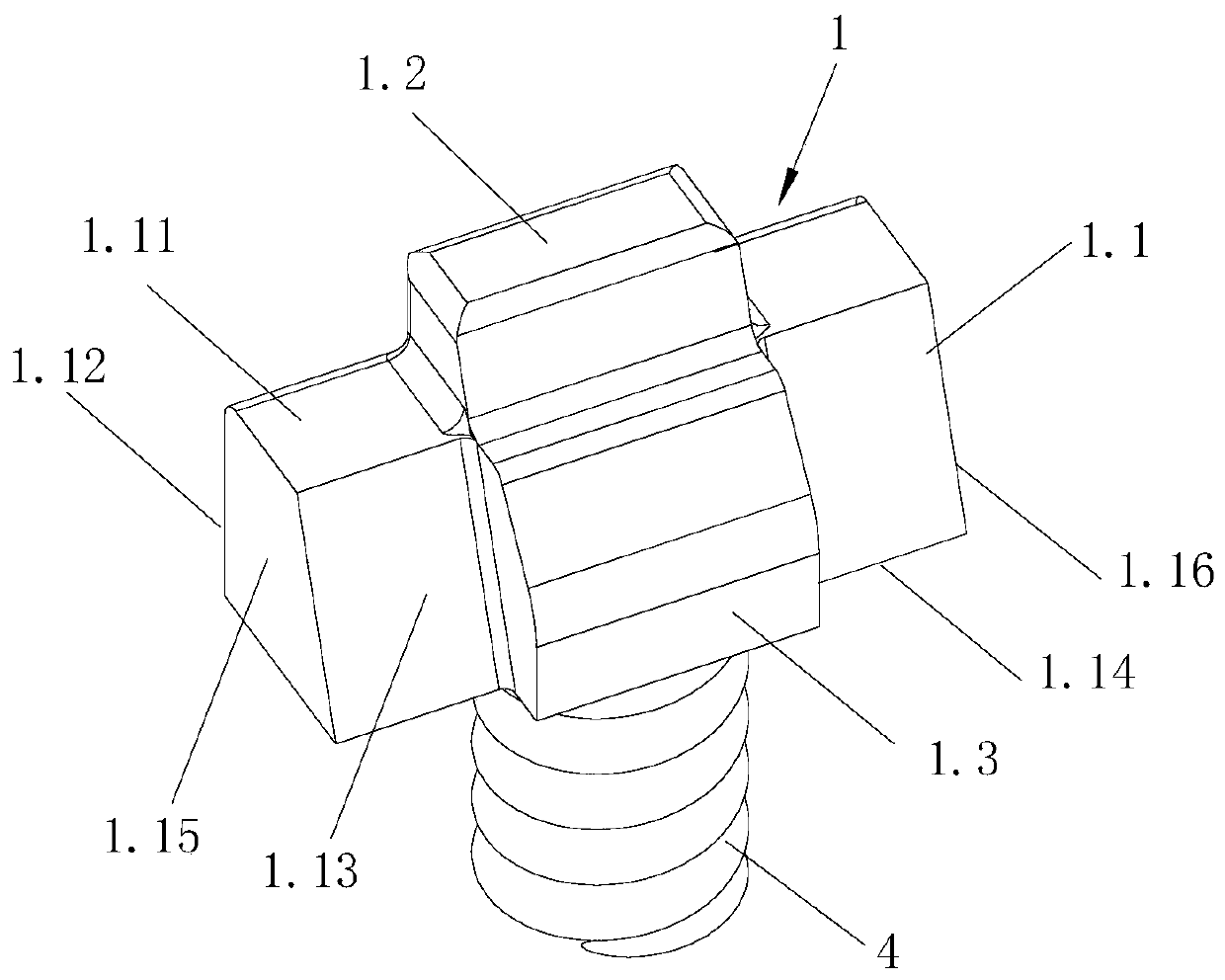

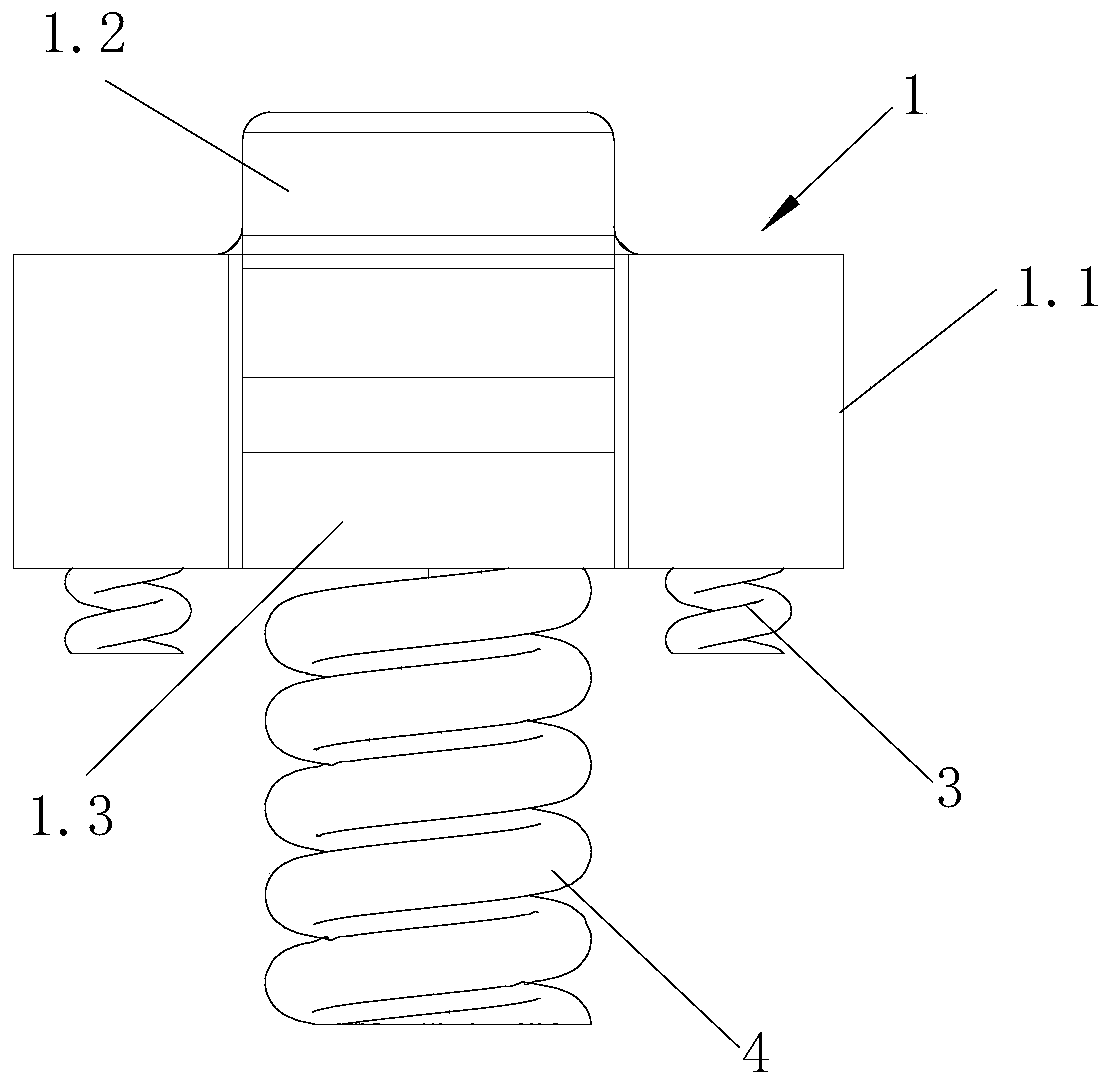

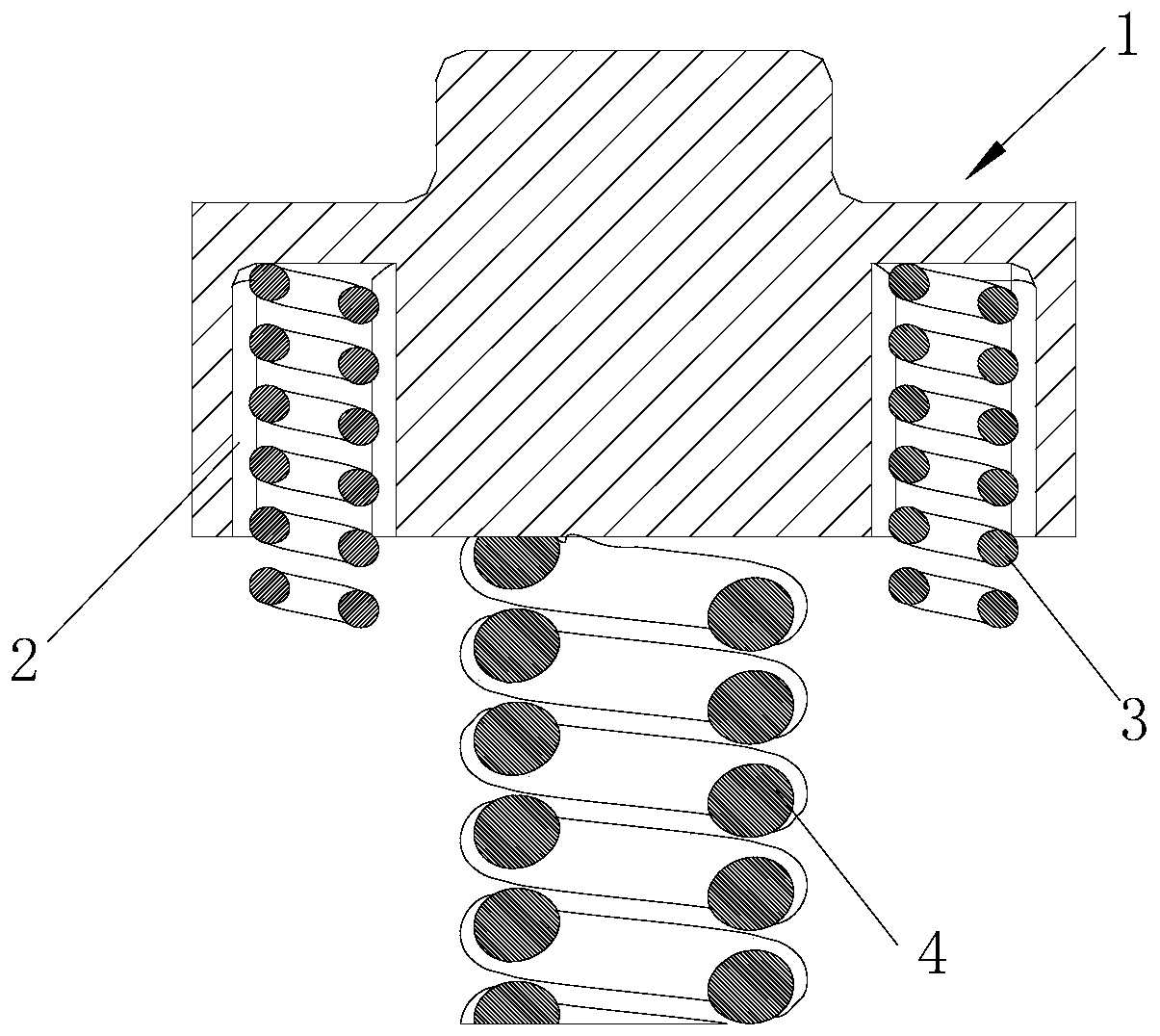

[0025] like Figure 1~3 The shown double-acting friction shock absorber for a railway freight car bogie is used to be arranged between the side frame 5 and the bolster 6, and includes a wedge block 1, which is a hard component made of metal material. The two ends of the length direction of the wedge block 1 are provided with accommodating cavities 2, and each accommodating cavity 2 is provided with a first spring 3, the top of the first spring 3 is fixedly connected with the top of the accommodating cavity 2, and the bottom end of the first spring 3 The bottom end extending downwards through the accommodation cavity 2 is fixedly connected with the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com