All-purpose welding bogie

A bogie and frame technology, which is applied in the directions of bogies, railway car body parts, transportation and packaging, etc., can solve problems affecting the applicability of the bogie, the unsatisfactory performance of the vibration damping device and the empty-weight vehicle adjustment device, and the poor frame structure. Science and other issues, to achieve the effect of easy manufacture and maintenance, low wheel and rail force, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

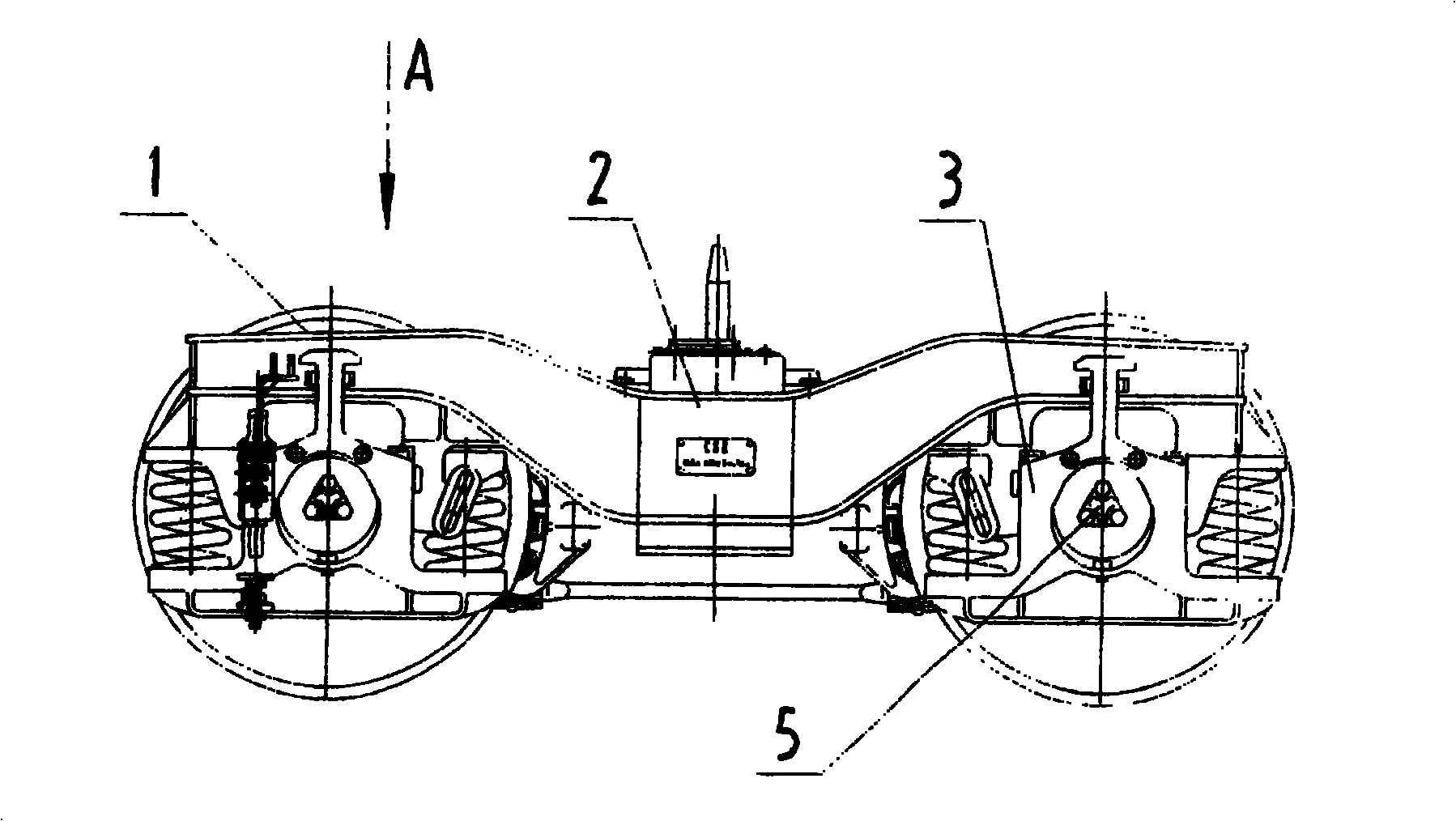

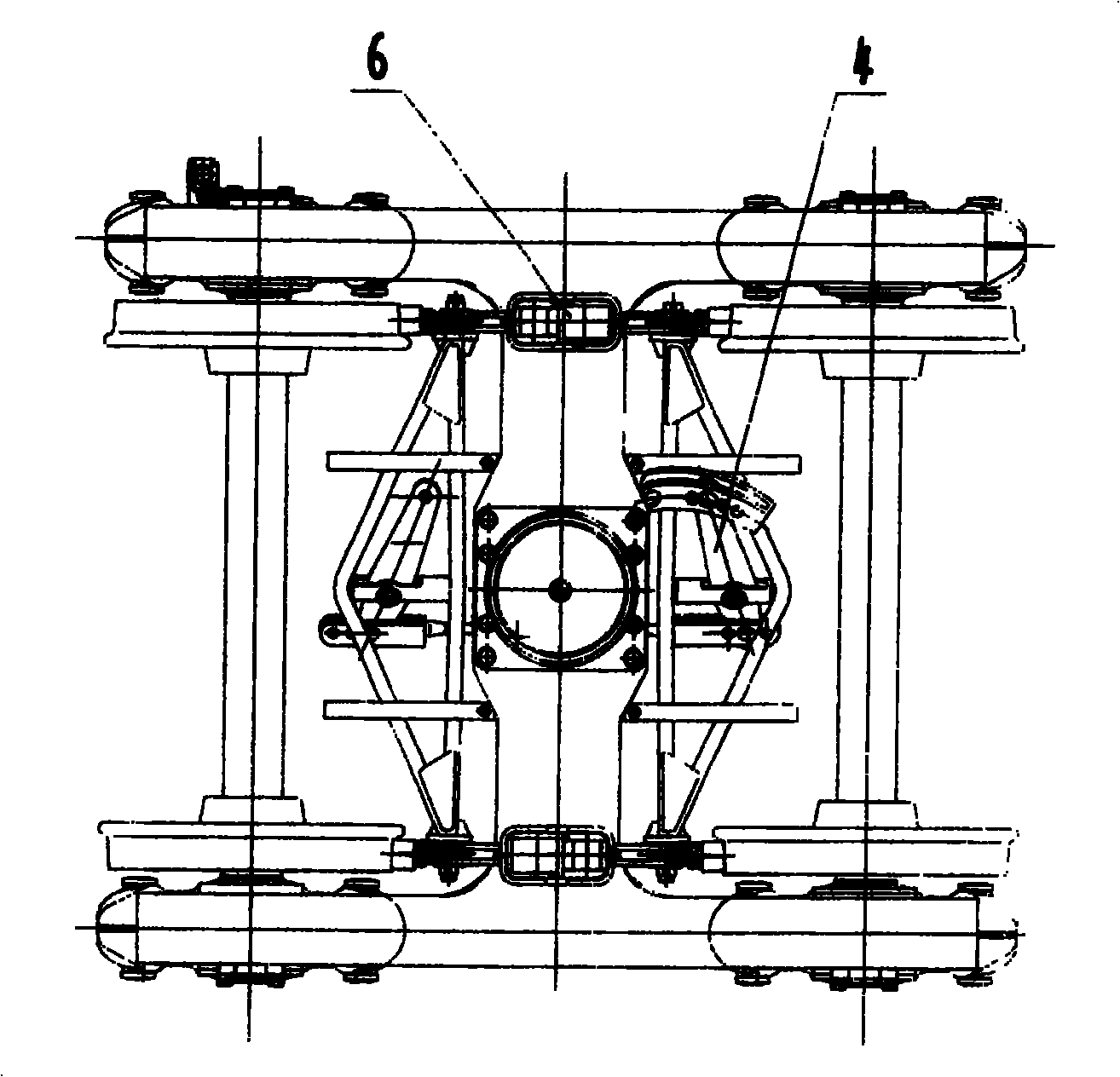

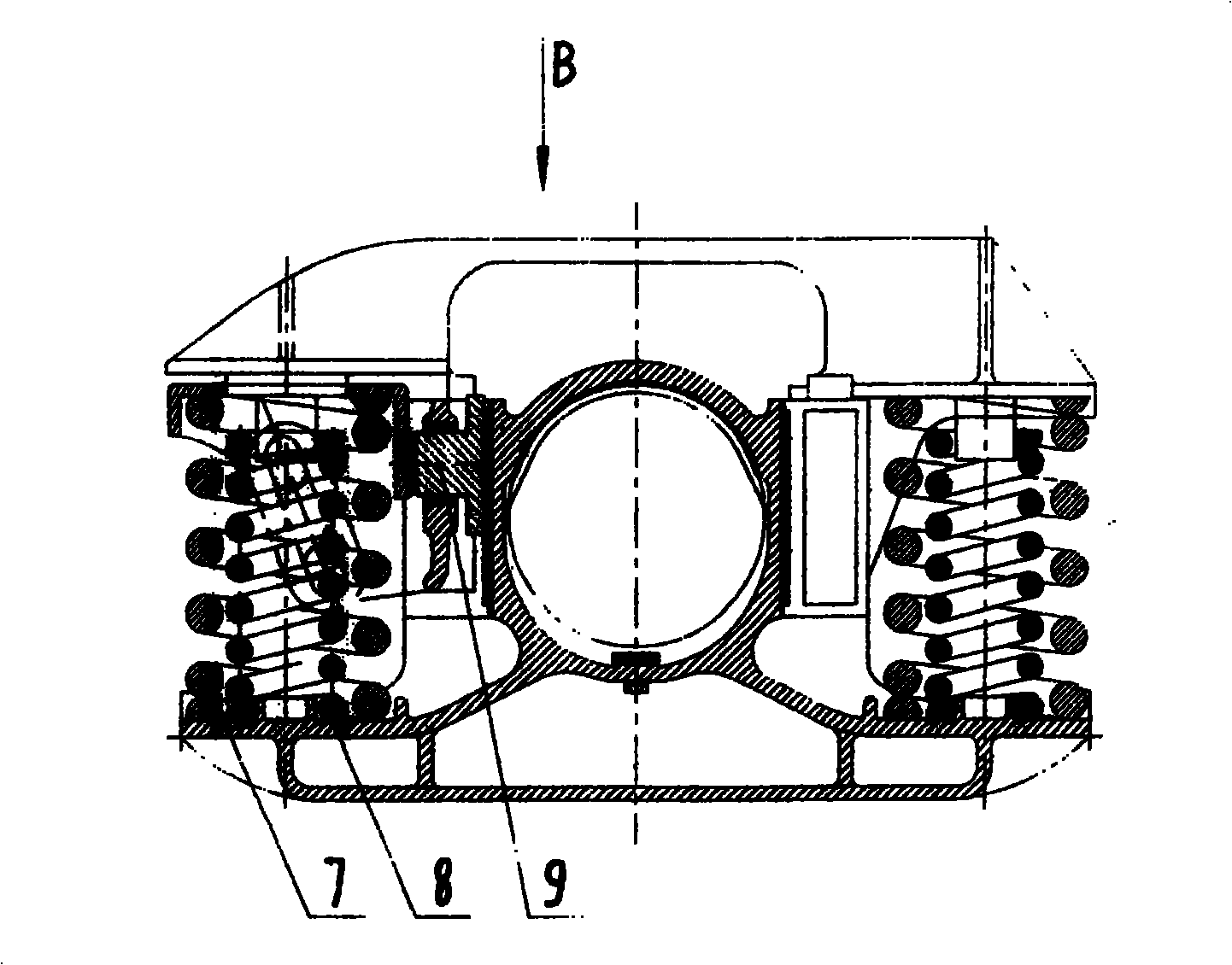

[0019] Referring to accompanying drawing, the present invention comprises H type welded frame 2, wheel set 1, axle box suspension device 3, damping device 5 and foundation braking device 4, frame (2) has sleeper side beam, axle box suspension device 3 has Axle box backing plate 12. The vibration damping device 5 has an inner circle spring 8 and an outer circle spring 7, a spring cap 10 is arranged at the top of the spring, suspension rings 11 are arranged on both sides of the spring, and a top sub-body 9 is arranged between the axle box suspension device 3 and the spring, Constitutes a Linole friction damper. A VTA valve empty-load truck adjustment device 6 is installed on the frame 2. The empty-load truck adjustment device 6 is installed with a valve 14 on the frame 2 through a valve hanger 13. Sense valve seat 15.

[0020] The cross-sectional structure of the frame can be a box structure, a single-web structure or other cross-sectional structures. The frame of the box-sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com