Auxiliary connecting device for wiring terminal

A technology for auxiliary connection devices and terminals, which is applied in connection, conductive connection, electrical component connection, etc., and can solve problems such as cumbersome operation and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

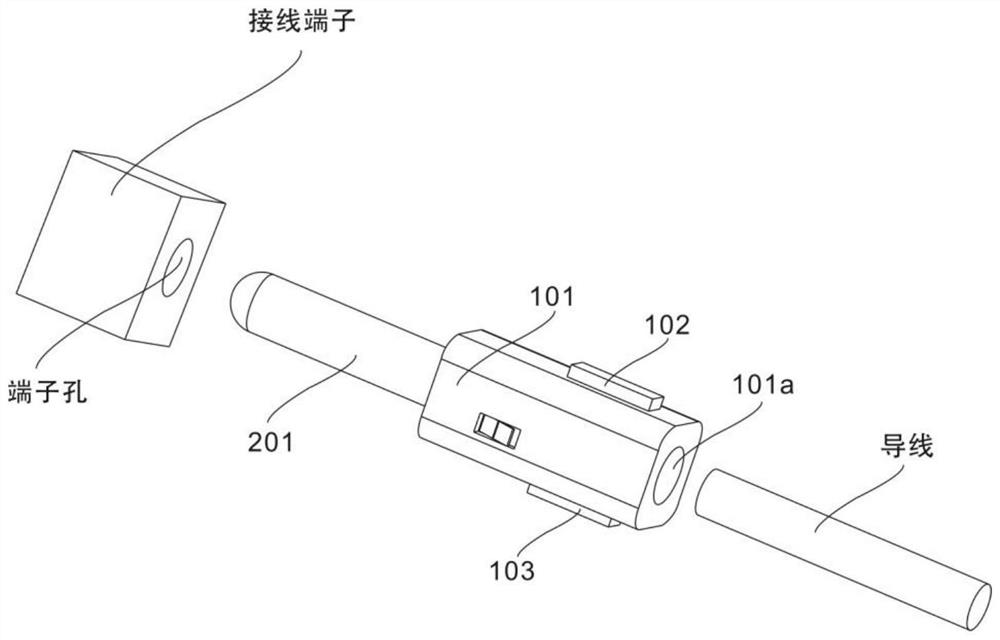

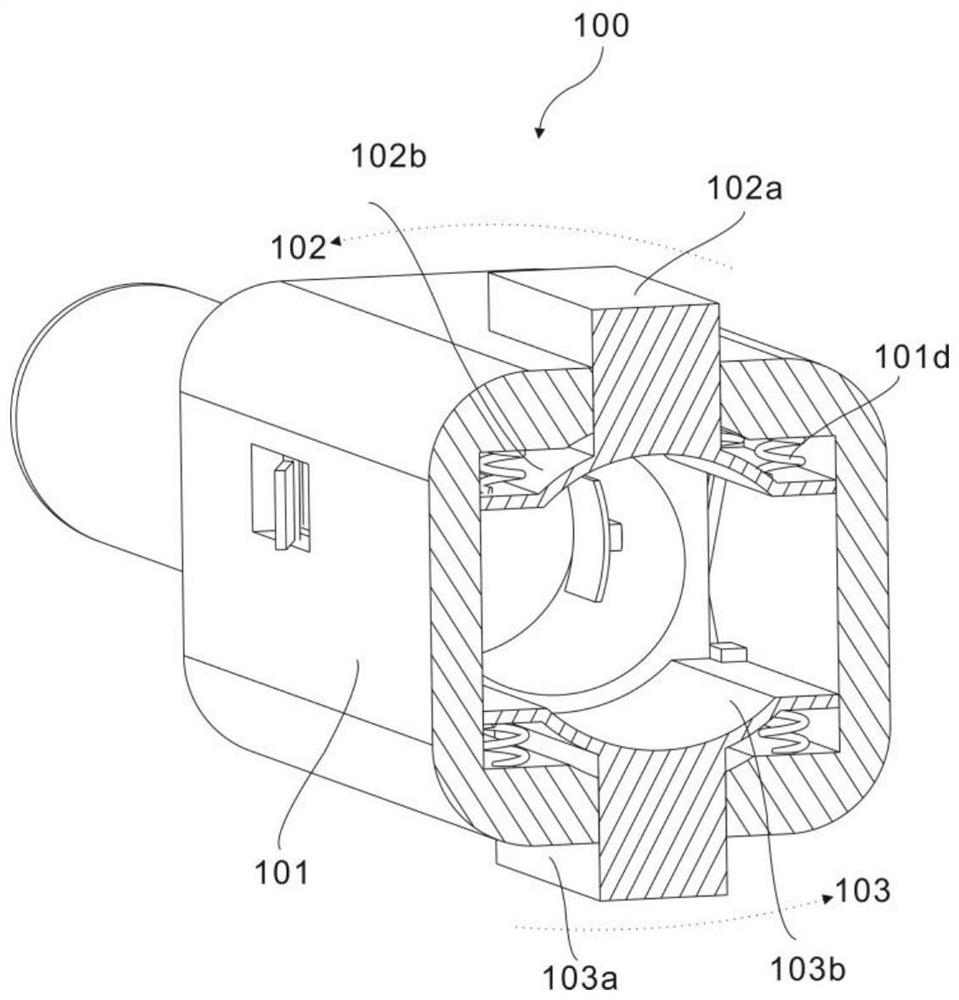

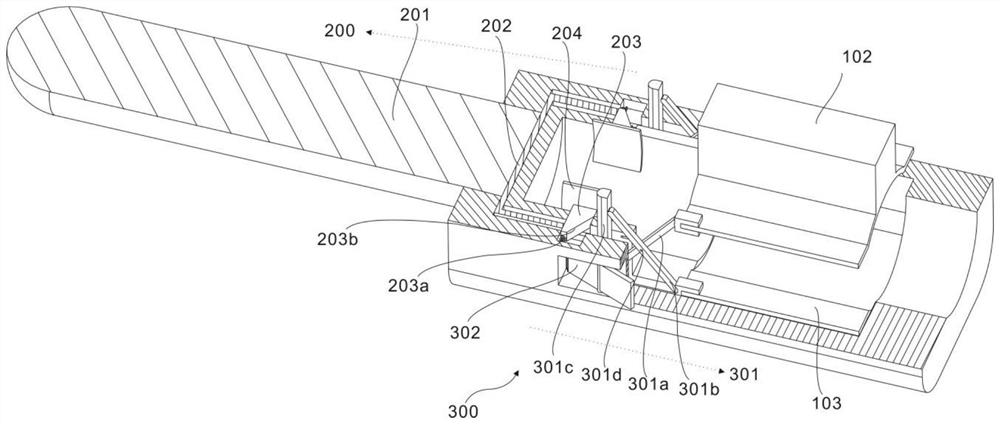

[0040] refer to Figure 1~5 , the present embodiment provides an auxiliary terminal connection device, including a clamping assembly 100, including a box body 101, a first clamping piece 102 and a second clamping piece 103, and the first clamping plate 102 and the second clamping plate 103 are symmetrical set in the box body 101;

[0041] The conductive assembly 200 includes a plug post 201, a conductive bar 202, a pusher block 203 and a contact plate 204. The plug post 201 is arranged at the end of the box body 101, and the conductive bar 202, the push block 203 and the contact plate 204 are set at the box body 101 Inside;

[0042] The conductive strip 202 is connected to the plug column 201 and the push block 203, and the contact plate 204 is arranged at the end of the push block 203;

[0043] The connection assembly 300 includes a pusher 301 and a lock 302 , the pusher 301 connects the clamping assembly 100 and the conductive assembly 200 , and the lock 302 is arranged on...

Embodiment 2

[0070] refer to Figure 1~6 The difference between this embodiment and the previous embodiment is that a side groove 101i is provided on the side of the box body 101, and the side groove 101i communicates with the accommodating groove 101e.

[0071] The locking member 302 includes a plywood 302a, a buckle 302b and a rotating shaft 302c. The buckle 302b is disposed at the end of the plywood 302a, and the plywood 302a is connected to the side groove 101i through the rotating shaft 302c.

[0072] The end of the vertical bar 301c facing the push block 203 is set as a second slope 301c-1, and the side of the vertical bar 301c is provided with a slot 302c-2.

[0073] In this embodiment, in order to maintain the clamping state of the clamping assembly 100, a locking member 302 is provided, and the locking member 302 can rotate around the rotating shaft 302c. state, the buckle 302b of the locking member 302 is located in the accommodating groove 101e, specifically on the moving path ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com