Skeleton structure of telescopic wing

A skeleton structure and wing technology, applied in the field of skeleton structure of retractable wings, can solve the problems of small variable range of wingspan, non-continuous change, cumbersome operation, etc., to achieve convenient processing and installation, convenient processing and installation, The effect of large wing folds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

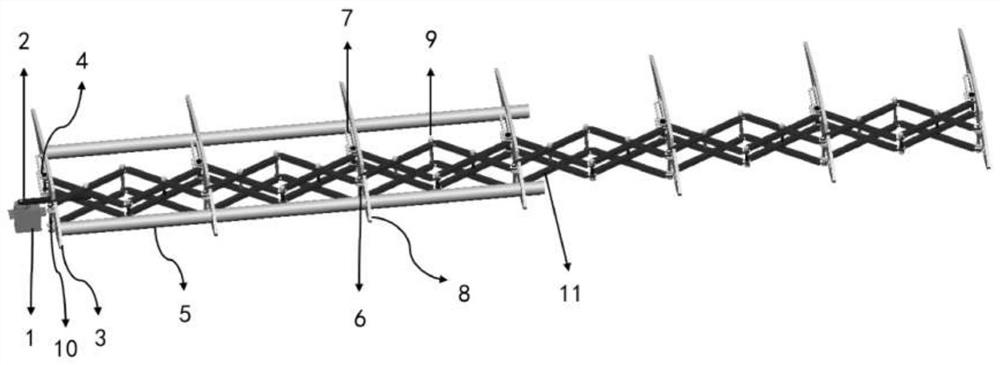

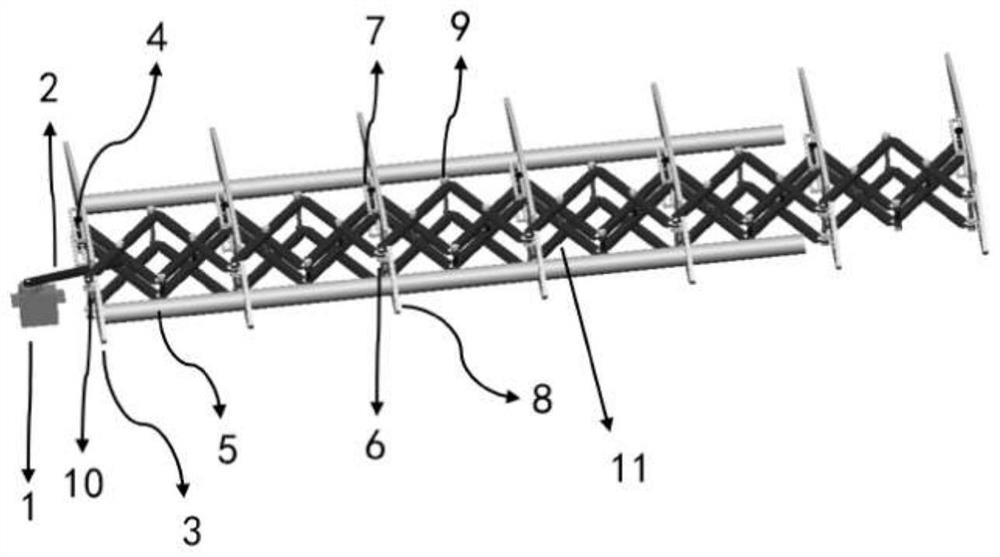

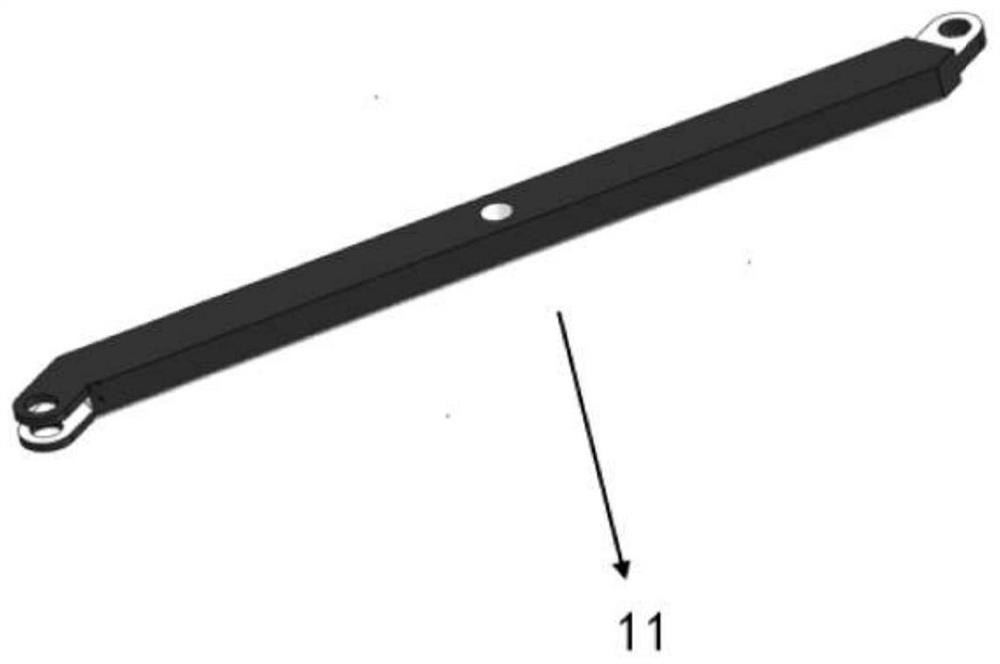

[0026] Such as figure 1 with figure 2 Shown, the skeleton structure of a kind of retractable wing of the present invention comprises steering gear driving device, wing rib, slide rail beam 5 and a plurality of motion module units; Said steering gear driving device comprises the steering gear fixed in the fuselage 1 and the steering gear connecting rod 2 connected with the steering gear 1, the steering gear driving device drives the expansion and expansion of the wings; the ribs include a fuselage rib 3 and a plurality of common ribs 8, between the ribs The common wing rib 8 can slide along the slide rail beam 5 through the connection of the movement module units; each movement module unit is composed of a plurality of transmission links 11 hinged.

[0027] Such as figure 2 As shown, when the steering gear 1 drives the steering gear connecting rod 2 to ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com