A variable camber wing

A wing and camber technology, which is applied in the field of variable camber wings, can solve the problems of destroying the continuity of the wing surface, reducing the aerodynamic characteristics of the aircraft, and being difficult to meet the flight conditions of multi-tasking, so as to broaden the adaptability and structure. Simple, reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

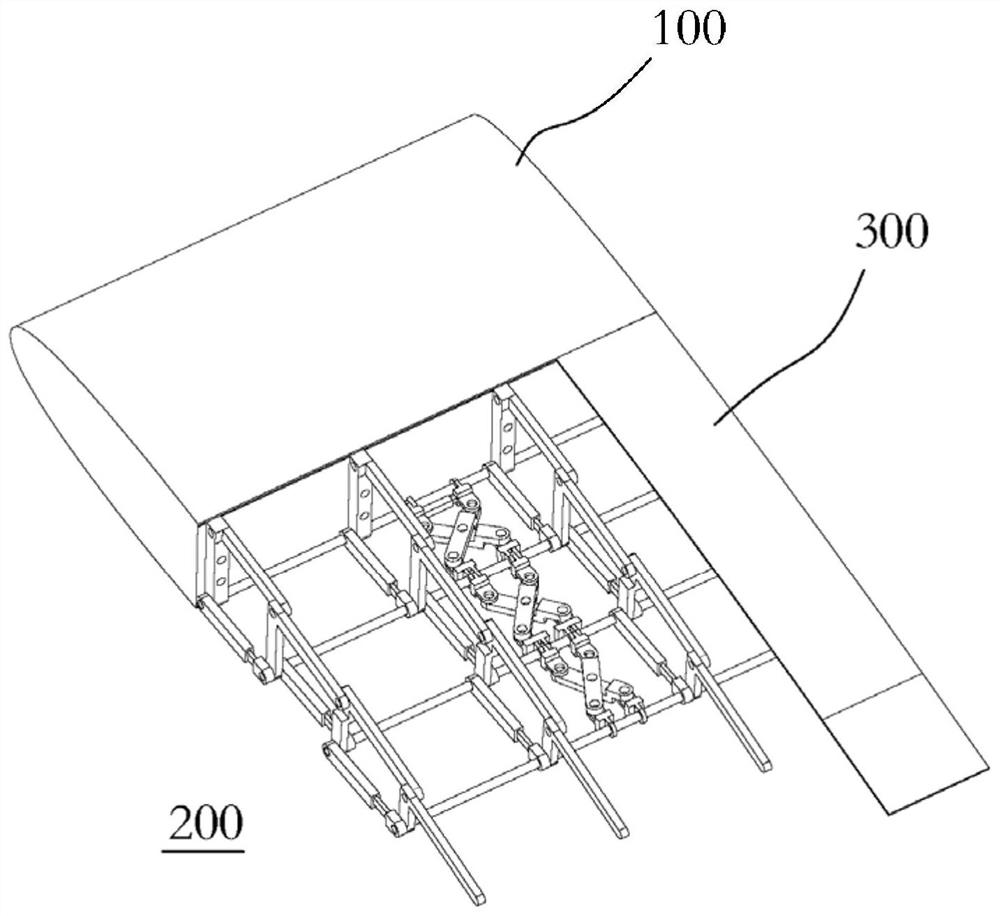

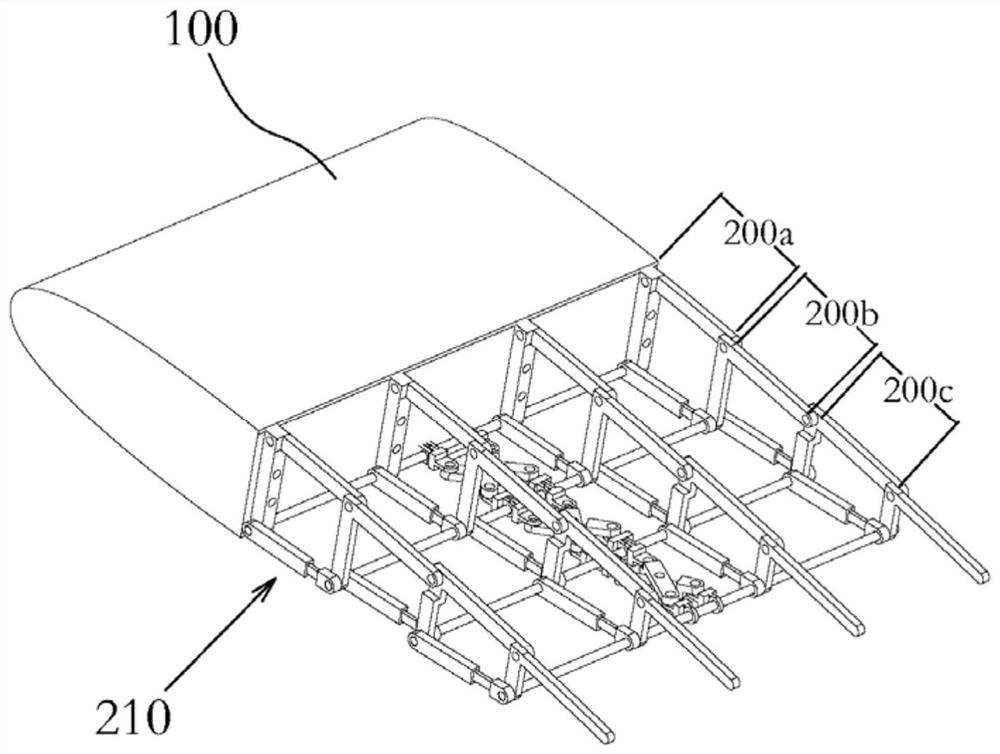

[0037] A variable camber wing, such as Figure 1-7 As shown, it includes a front wing segment 100 with constant camber, a rear wing segment 200 with variable camber, and a wing skin 300 .

[0038] The wing skin 300 in this example is connected with the front section 100 of the wing in a riveted manner. In order to better follow the change of the curvature of the trailing edge section 200 of the wing, the wing skin 300 adopts an elastic skin to follow the shape of the wing. Adaptive deformation occurs when the trailing edge section 200 becomes curved.

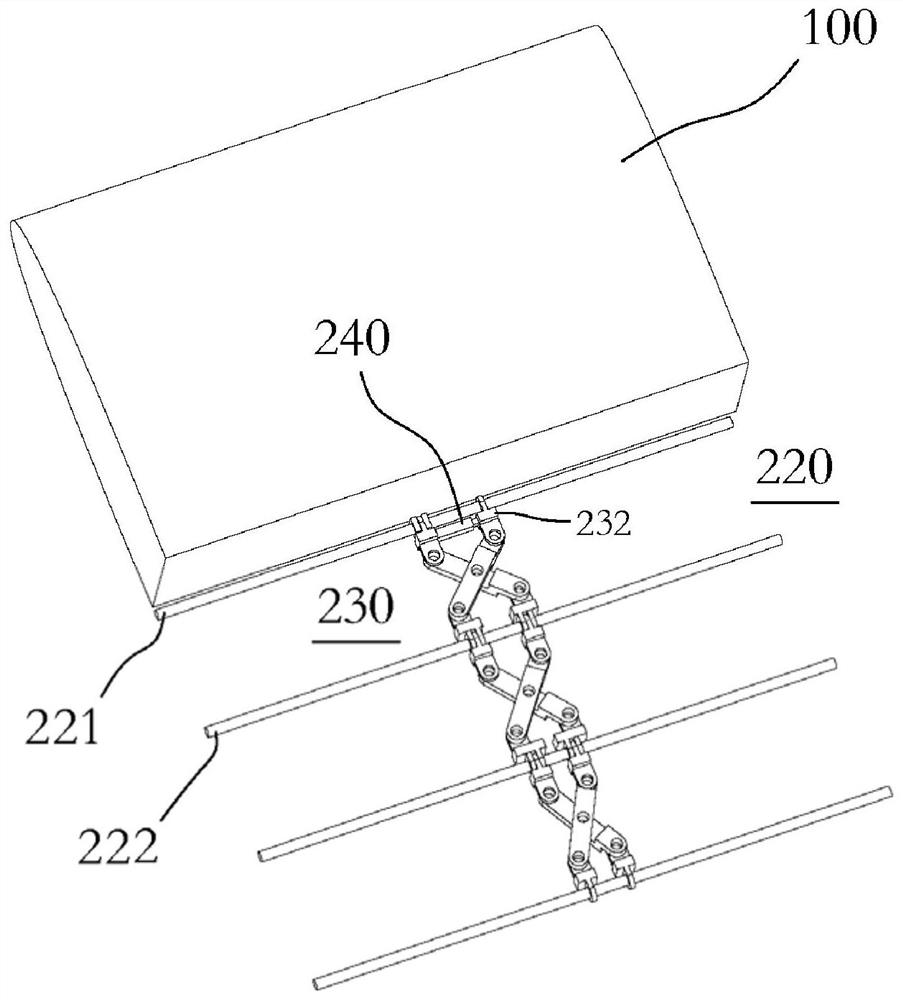

[0039] The trailing edge section 200 of the wing includes three rib joints 200a, 200b, and 200c connected in series. The structure of the rib joint 200a closest to the leading edge of the wing will be described in detail below. The rib joint 200 a includes four closed-loop rod mechanisms 210 , a parallel rod mechanism 220 , a scissor mechanism 230 and a driving mechanism 240 .

[0040] Such as Figure 5 As shown, the closed-l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com