Gantry waveform guardrail plate bending machine

A gantry type and bending machine technology, applied in the field of guardrails, can solve problems such as difficulty in bending and forming of fence panels, and achieve the effects of smooth appearance, easy movement and high bending efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

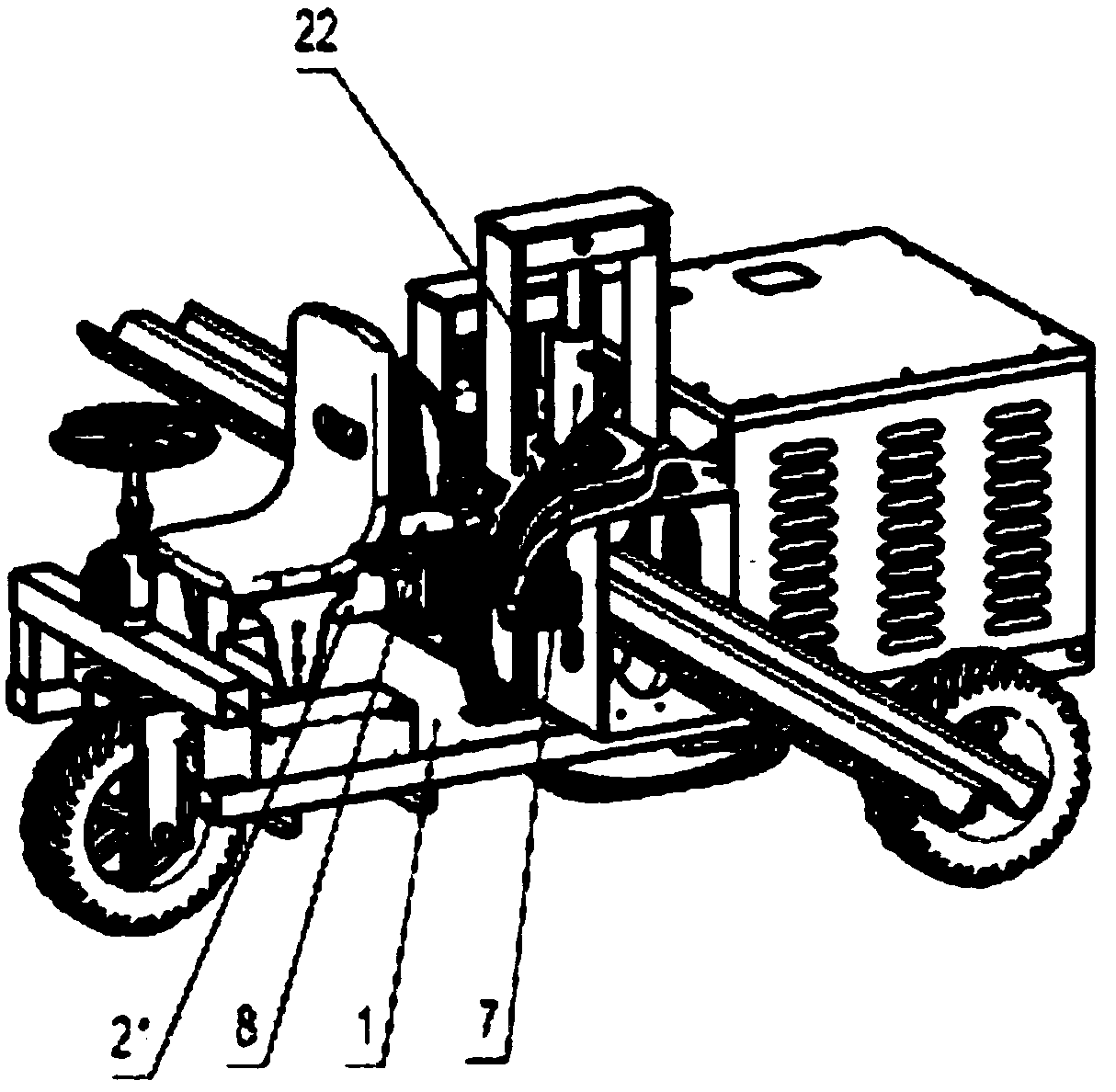

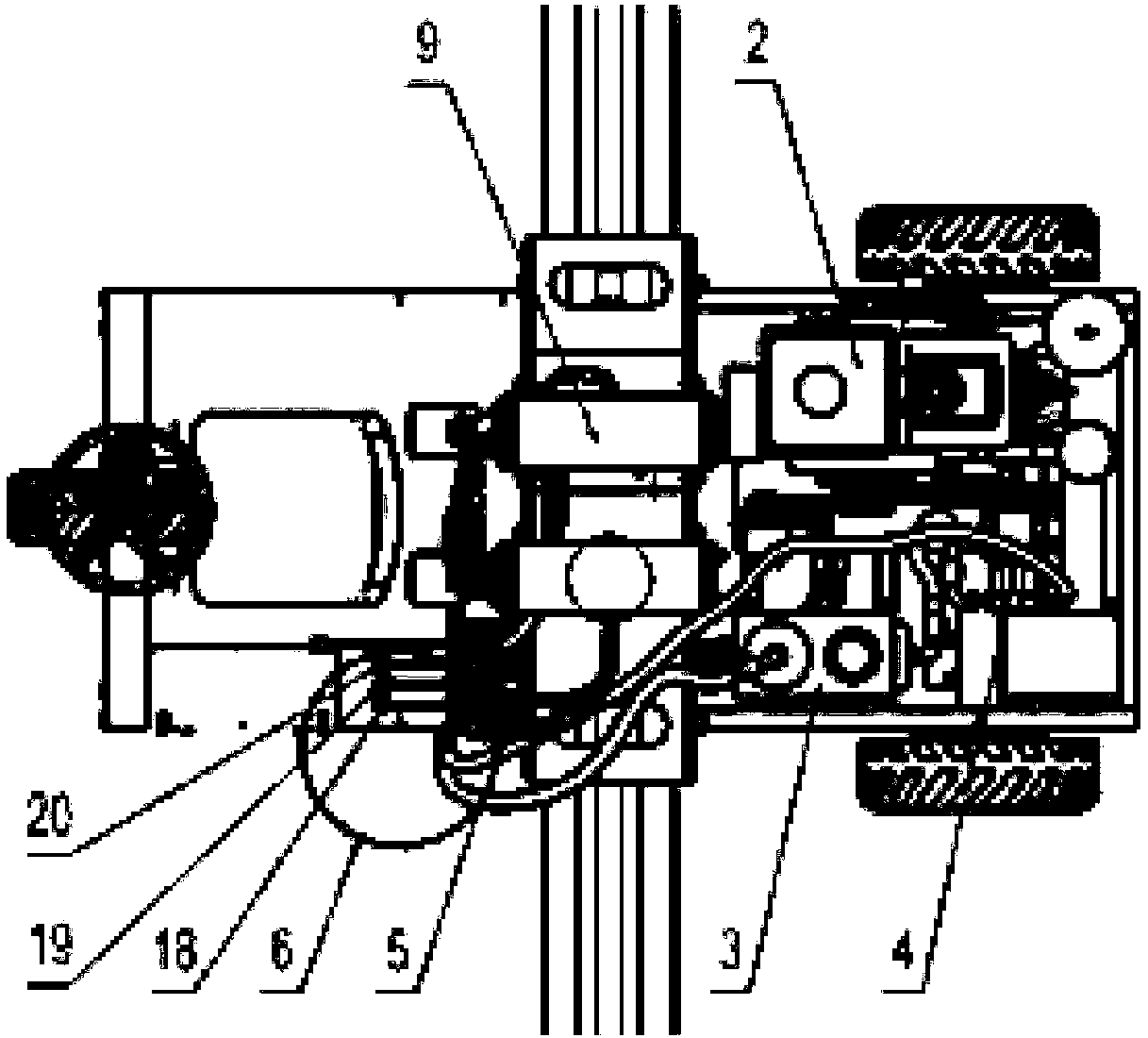

[0033] Such as Figure 1 to Figure 8 As shown, the gantry-type corrugated guardrail panel bending machine includes a wheeled mobile carrier platform 1, and the wheeled mobile carrier platform 1 is provided with a gantry-type box forming mechanism 9, a diesel engine 2, a gear-type hydraulic motor 4, a hydraulic high-pressure oil pipe 5 and Handle-type multi-way operation valve 6, the handle-type multi-way operation valve 6 is connected with hydraulic cylinder I7, hydraulic cylinder II22, hydraulic cycloid motor I8, hydraulic cycloid motor II21 and hydraulic cycloid motor III10;

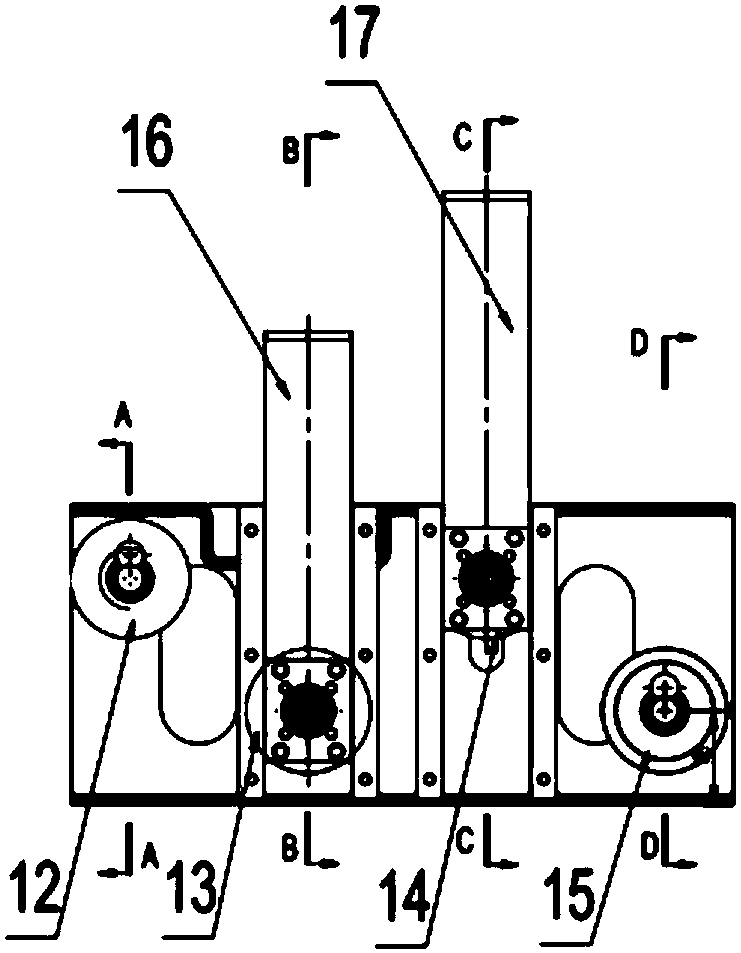

[0034] The gantry-type box forming mechanism 9 includes a box body, a wave roller I12, a wave roller II13, a wave roller III14, a wave roller IV15, a gantry I17 and a gantry II16, and the wave roller I12 and the wave roller IV15 are fixedly assembled on the box , the wave roller Ⅱ13 and the wave roller Ⅲ14 are respectively assembled on the gantry Ⅰ17 and the gantry Ⅱ16;

[0035] The gantry I17 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com