Feeding device

A feeding device and feeding technology, which is used in the field of feeding devices for filamentous, plastic and fibrous materials, can solve the problems of agglomeration, material breakage, and unsmooth feeding of materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0027] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below.

[0028] The inventor specially designed the feeding device of the present invention for the characteristics of plastics, filamentous, fibrous and other materials that are polymorphic and easily melted and bonded when heated.

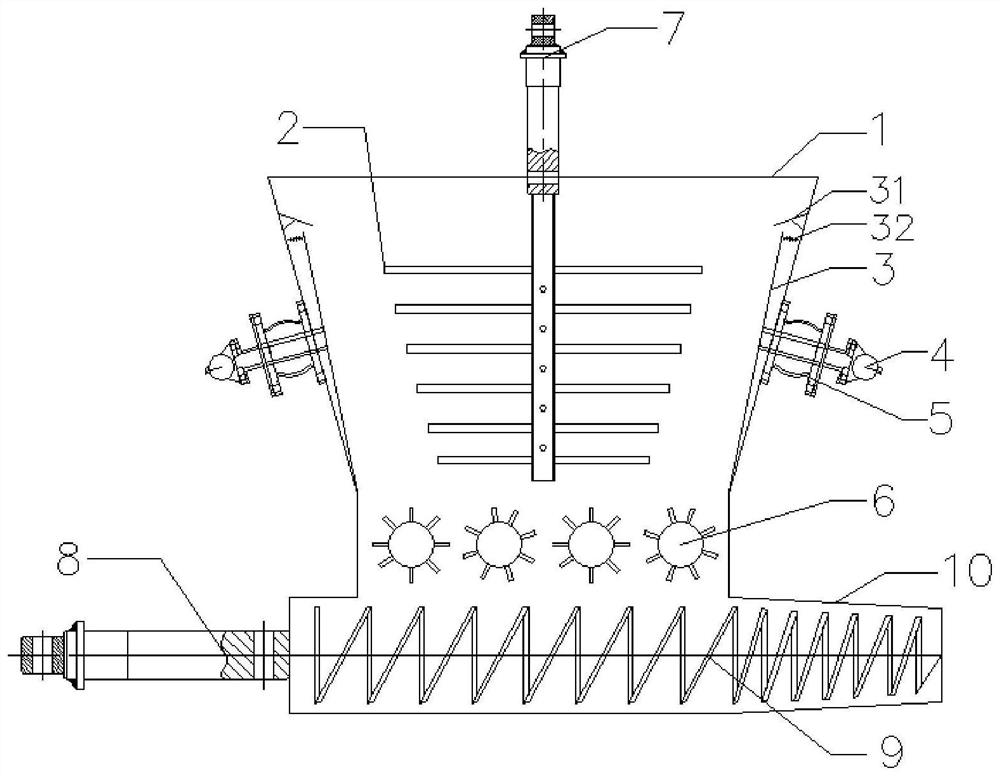

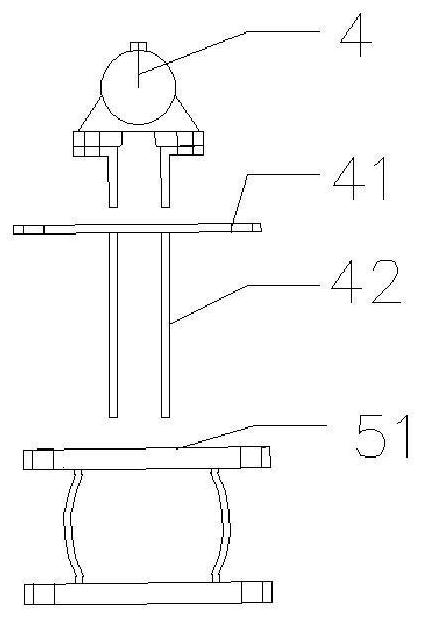

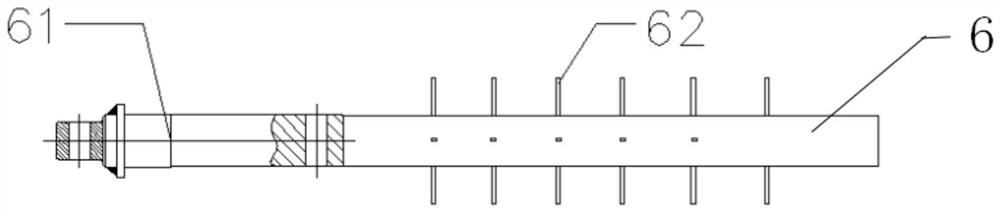

[0029] The feeding device of the present invention includes a silo body, a stirring assembly, at least one vibrating assembly, at least one roller shaft blanking assembly and a screw feeder, wherein

[0030] The stirring assembly is installed on the vertical central axis of the silo body and extends from the top of the silo body to the bottom of the silo body for stirring materials;

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com