Pneumatic control-based multi-filament spiral contact test device and method inside hoisting wire rope

A technology of pneumatic control and testing equipment, which is applied to measuring equipment, using stable tension/pressure to test material strength, testing wear resistance, etc., can solve problems such as inability to complete, improve accuracy, eliminate influencing factors, and simplify structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] The technical solutions of the present invention will be described in detail below with reference to specific embodiments and accompanying drawings.

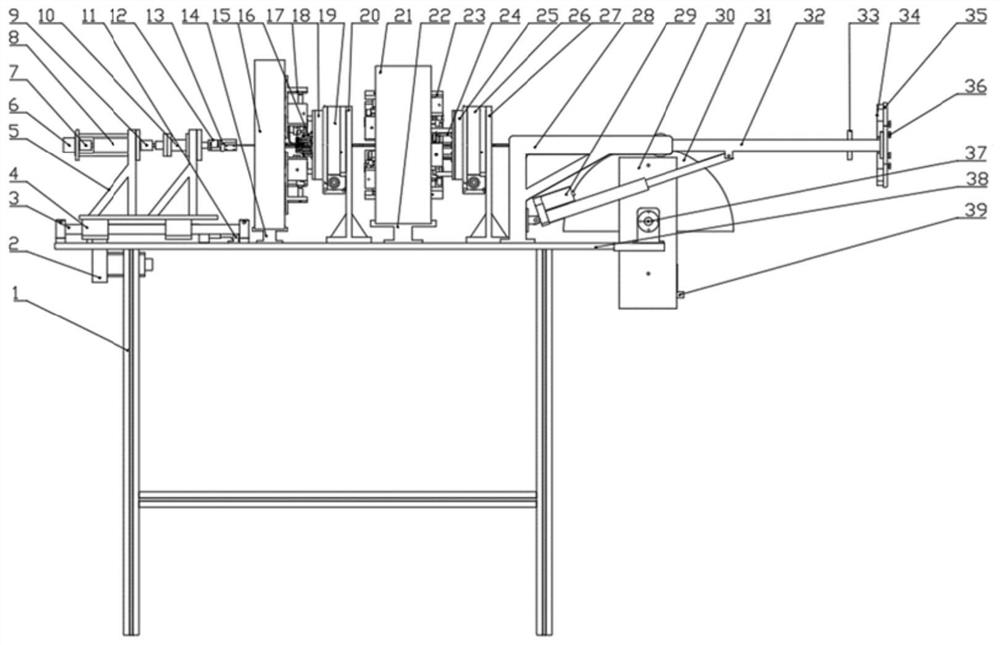

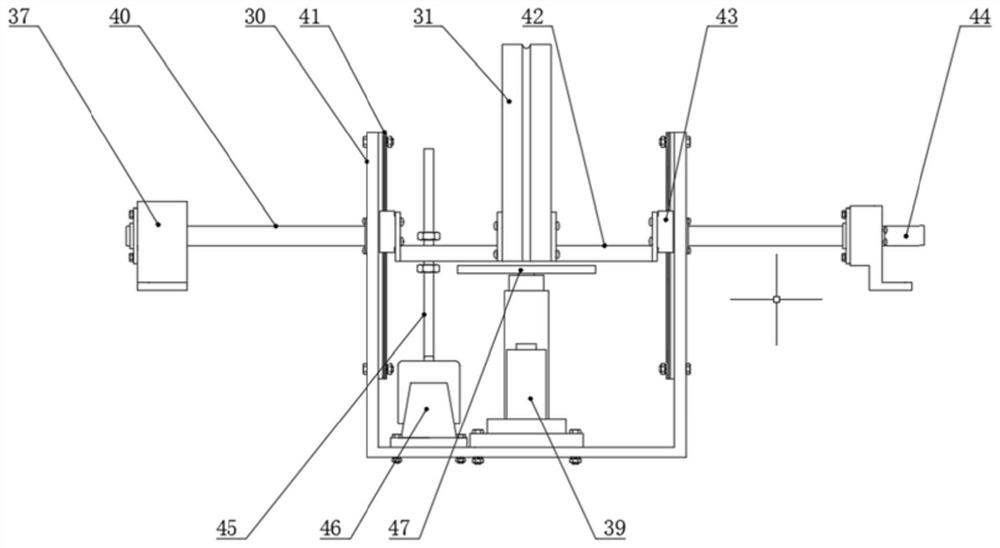

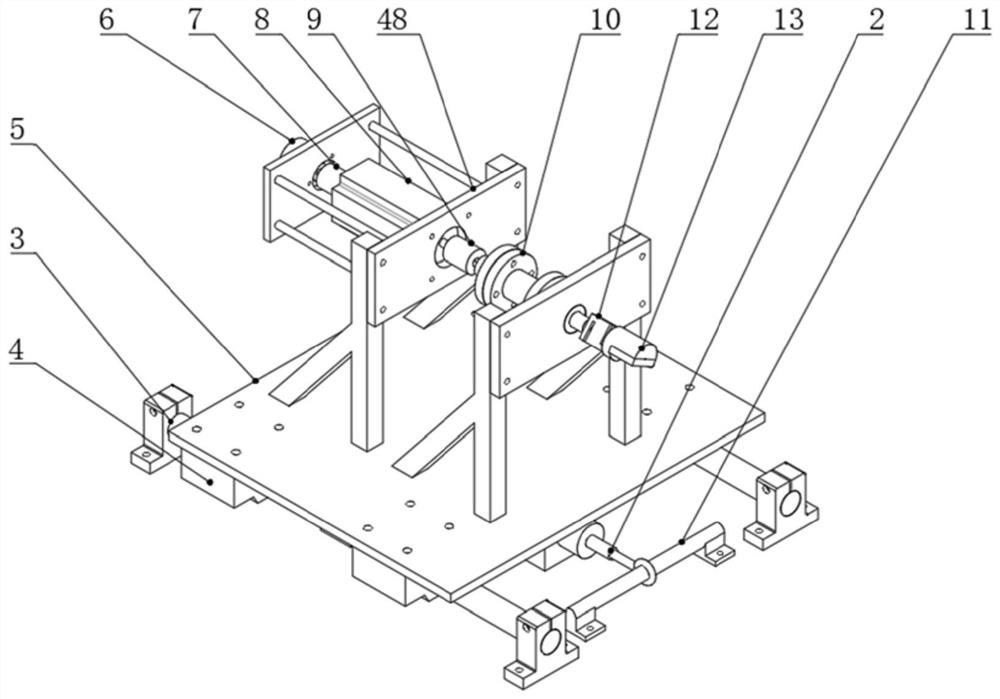

[0087] like Figure 1-8 , Based on the pneumatic control of the internal multi-filament spiral contact test device of the steel wire rope, it includes a workbench, a multi-filament spiral contact mechanism inside the steel wire rope placed on the workbench, a multi-filament spiral contact mechanism inside the steel wire rope and a drum loading mechanism;

[0088] The workbench includes a profile column 1, a workbench surface 38 supported by four columns, bolt holes on the workbench for fixing various components, and rectangular slots for arranging components.

[0089] In this embodiment, one end of the central steel wire is connected to a stretching and twisting compound mechanism, and the other end is fixed to one end of the work table 38, wherein the stretching and twisting compound mechanism includes a stretching mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com