Pneumatic control-based lifting steel wire rope internal multi-wire spiral contact testing device and method

A technology of pneumatic control and testing device, which can be used in measuring devices, using stable tension/pressure to test material strength, testing wear resistance, etc., and can solve problems such as inability to complete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] The technical solution of the present invention will be described in detail below in combination with specific embodiments and accompanying drawings.

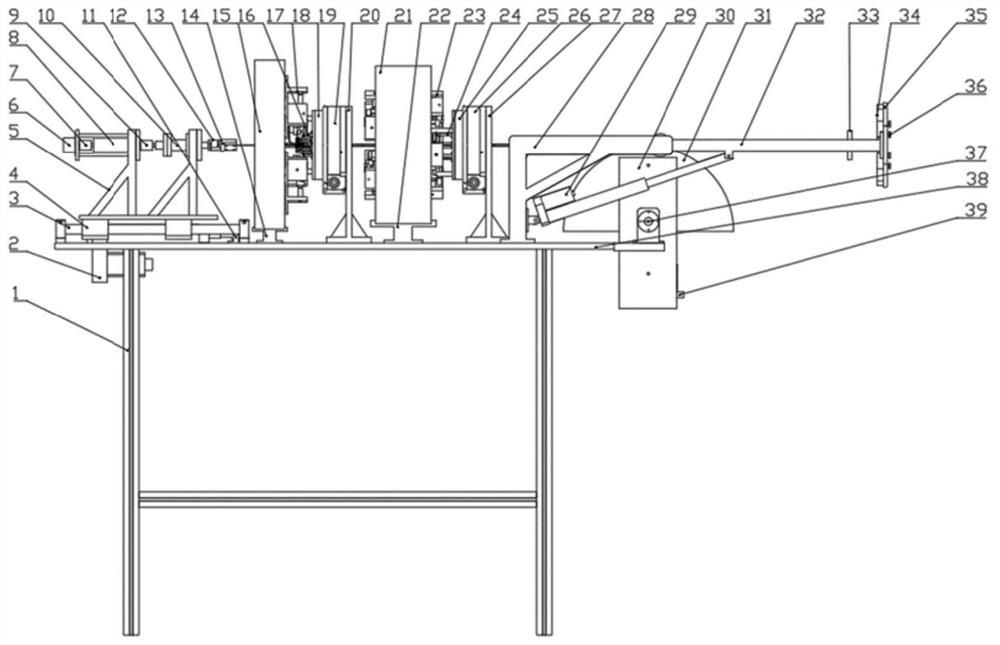

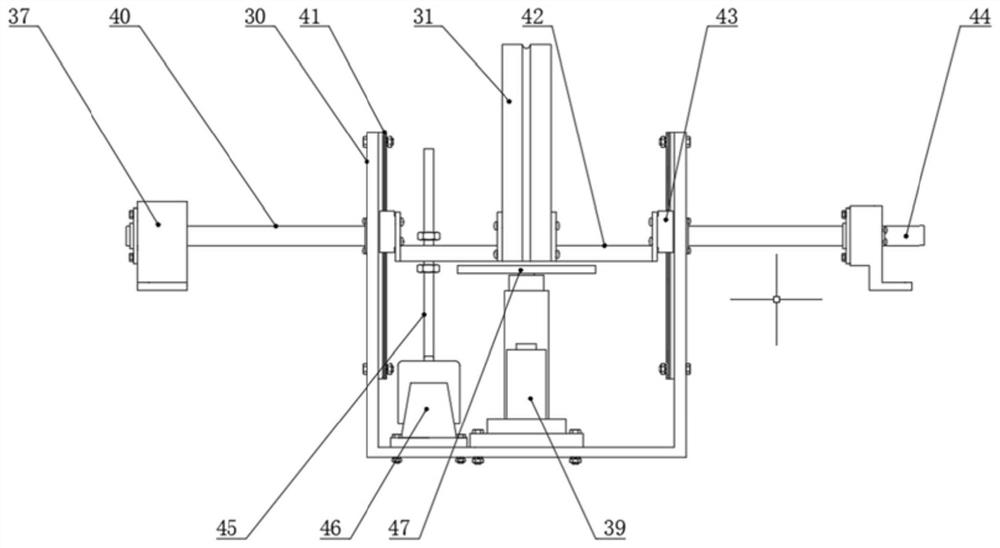

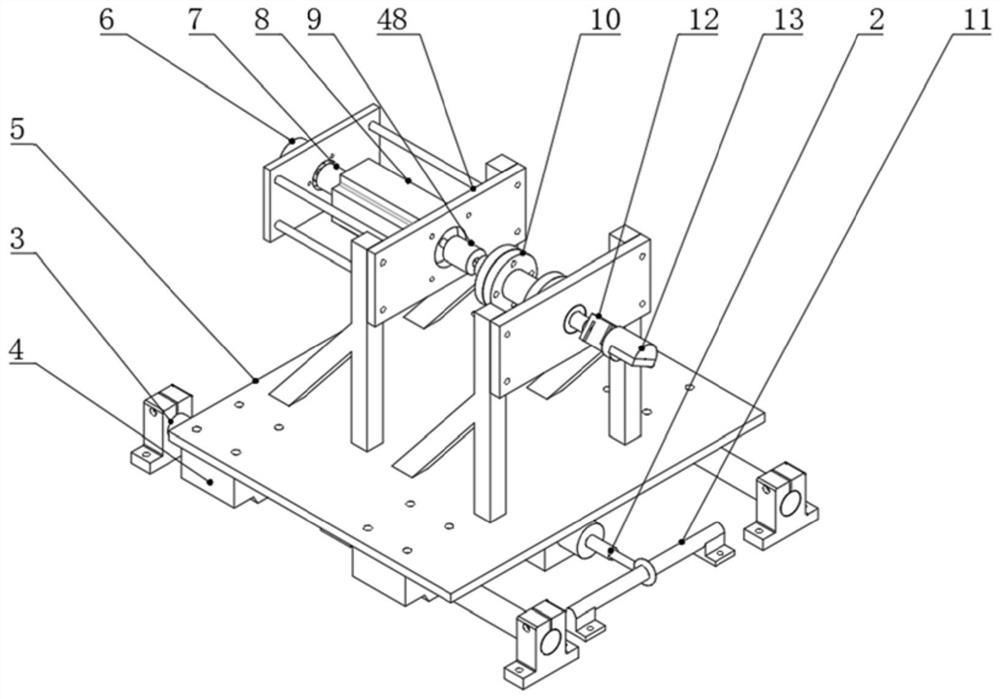

[0087] Such as Figure 1-8 , an internal multi-wire helical contact test device based on pneumatic control, including a worktable, an internal multi-wire helical contact mechanism placed on the workbench, a multi-wire loading mechanism inside a steel wire rope, and a drum loading mechanism;

[0088] Workbench comprises profile column 1, the workbench top 38 that is supported by four columns, the bolt hole that is used to fix each component on the worktable and the rectangular groove that each component is opened in order to arrange.

[0089] In this embodiment, one end of the central steel wire is connected to a stretching and torsion compound mechanism, and the other end is fixed to one end of the worktable 38, wherein the stretching and torsion compound mechanism includes a stretching mechanism and a torsion mechanism;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com