Patents

Literature

54results about How to "Eliminate influencing factors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

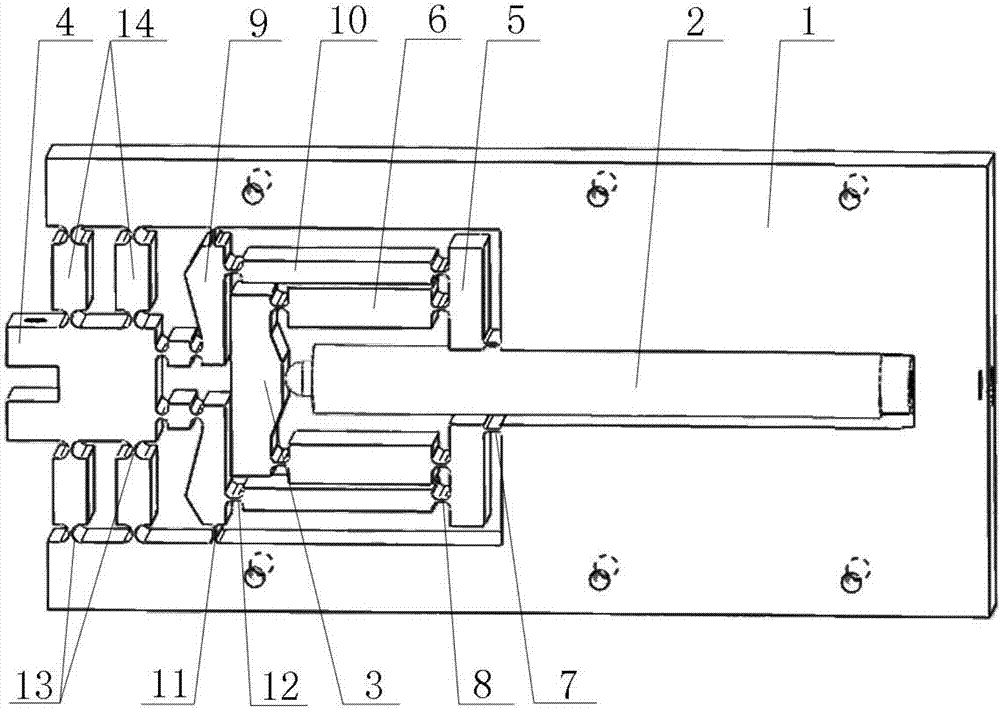

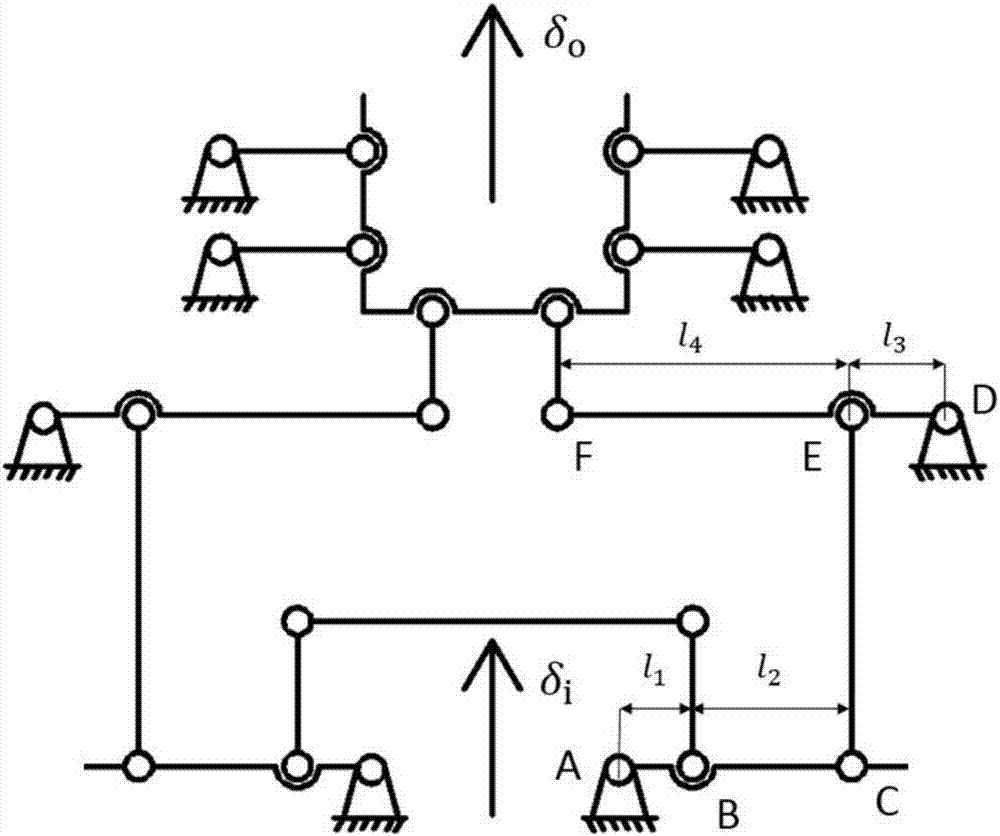

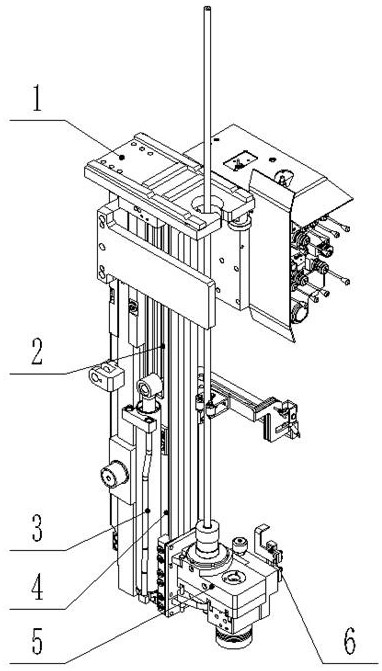

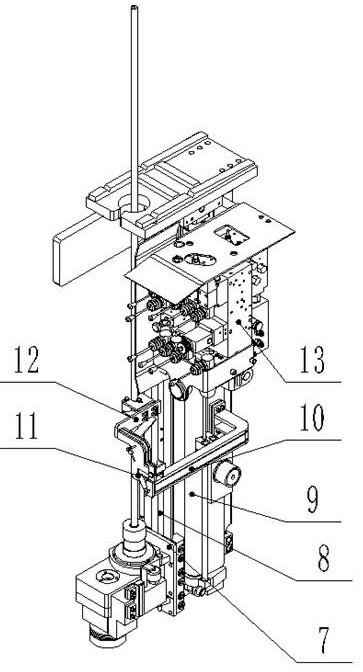

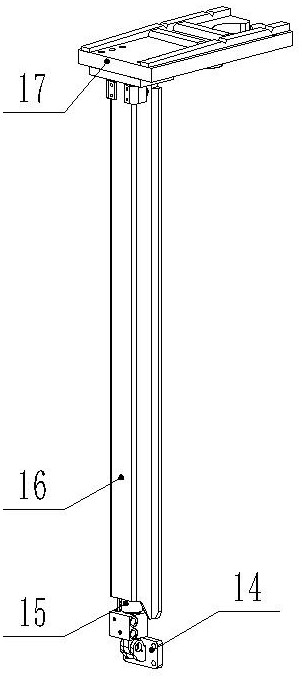

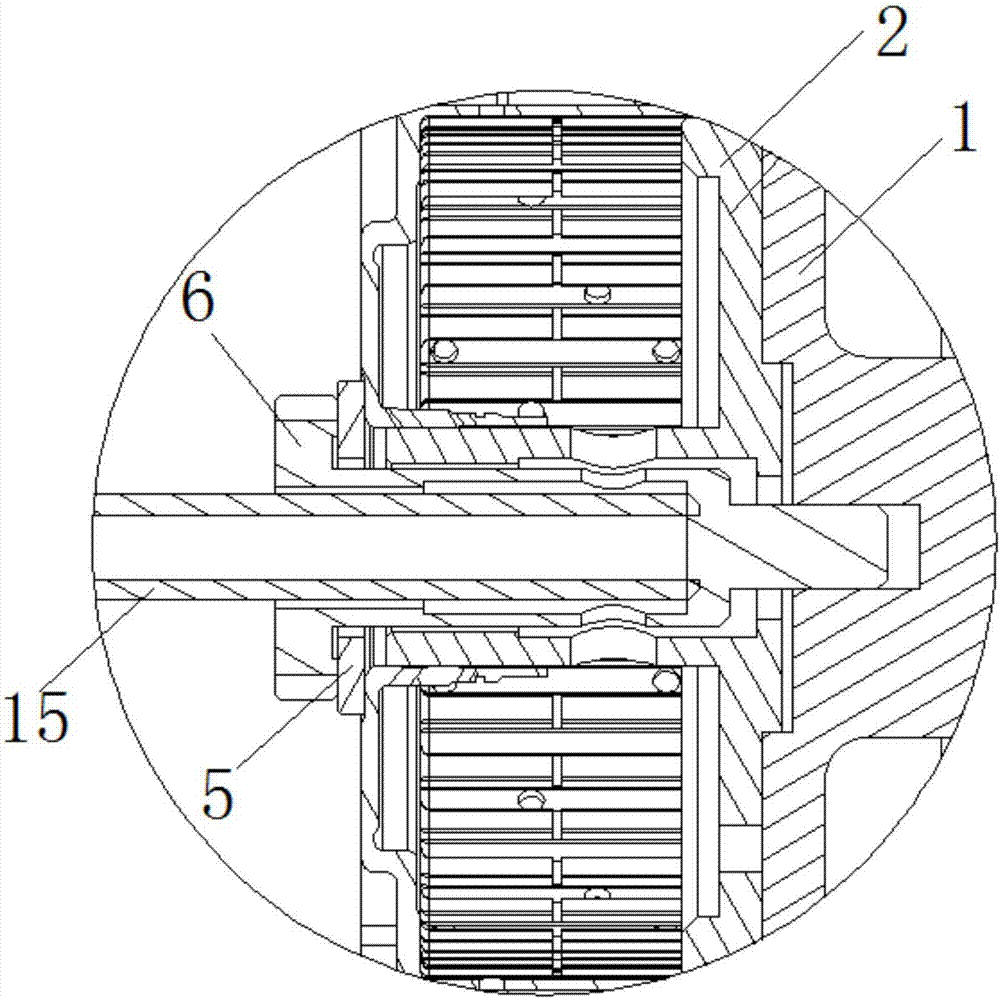

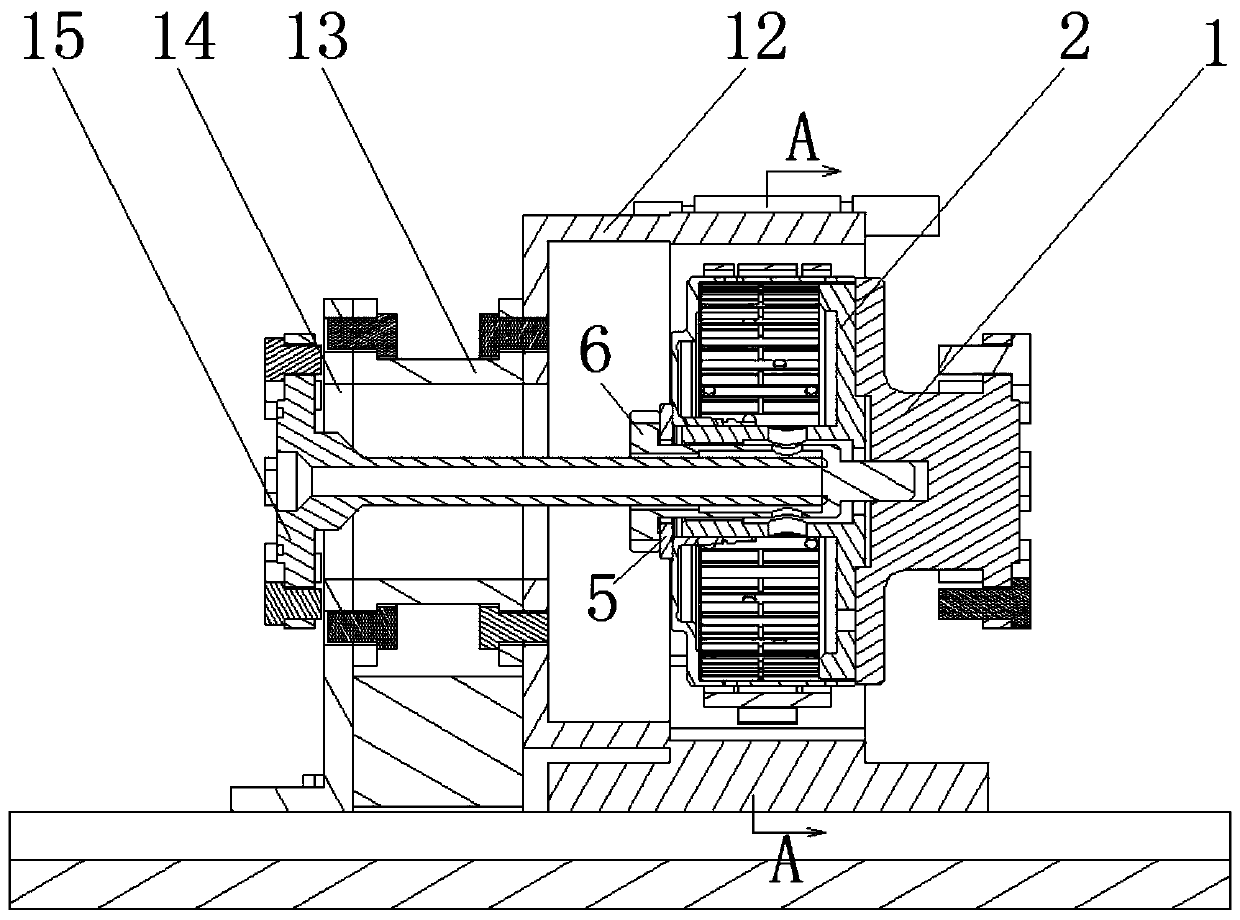

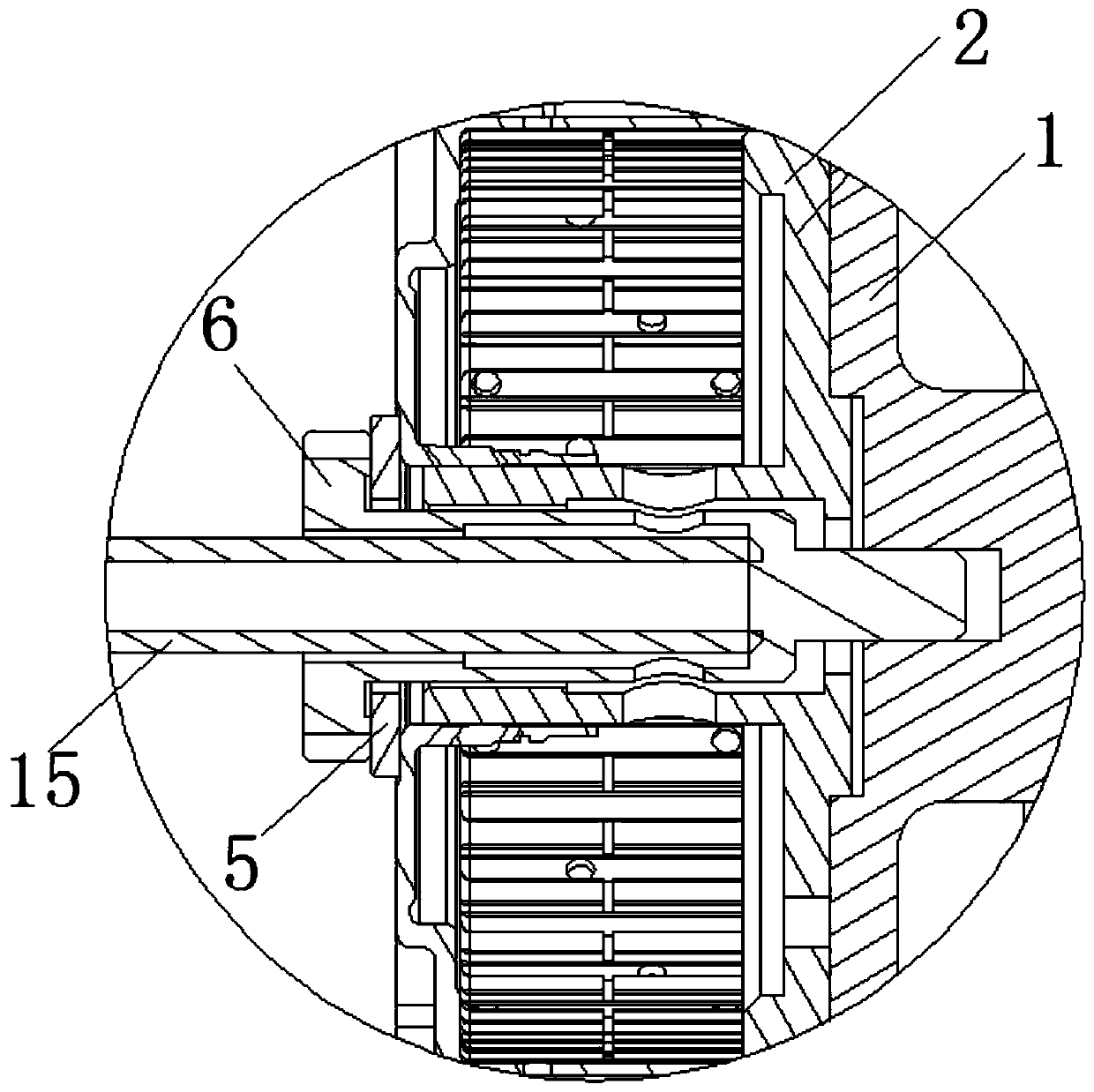

Long-stroke fast tool servo device

PendingCN106975961AIncrease the itineraryHigh positioning accuracyFeeding apparatusAxial displacementAxis of symmetry

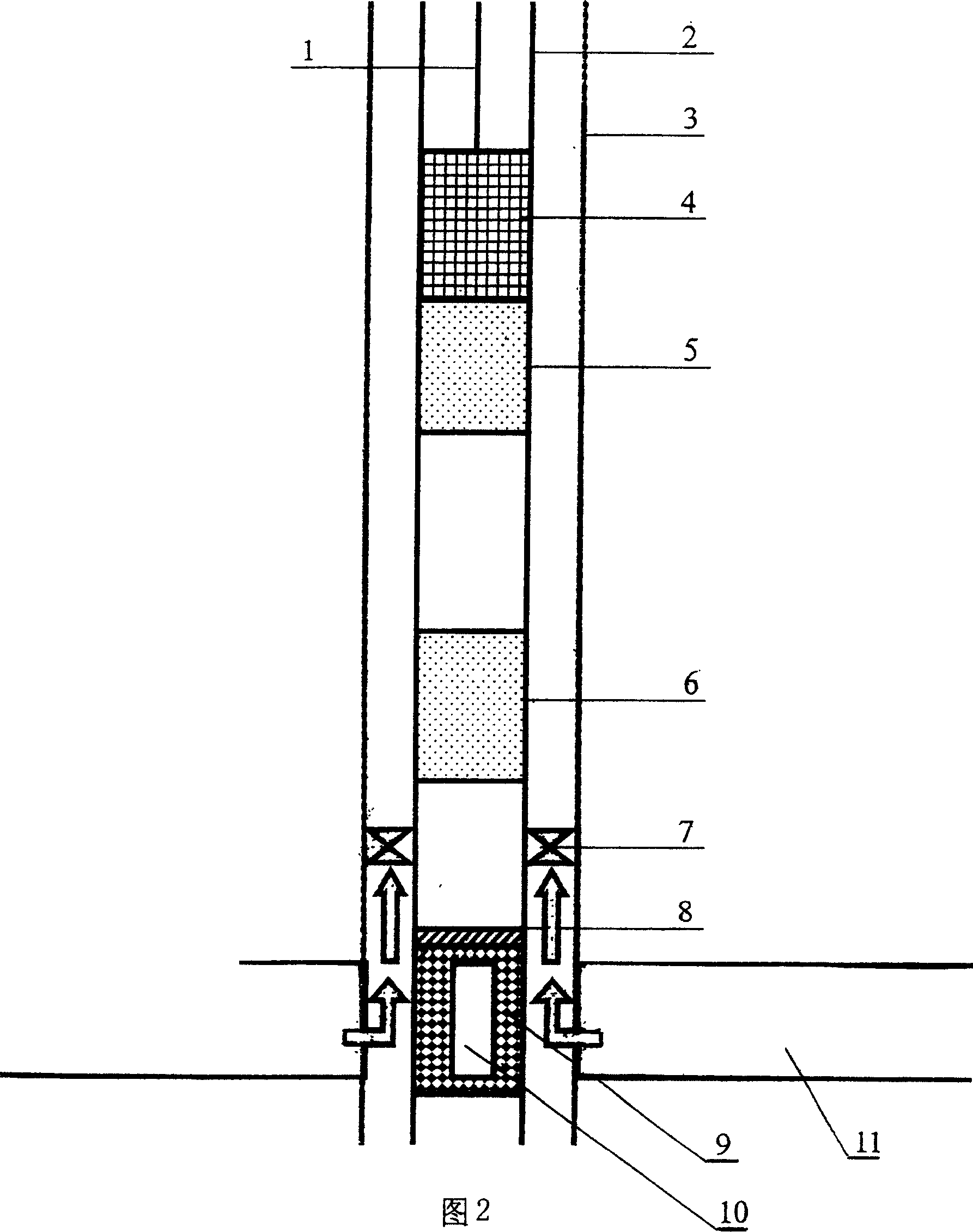

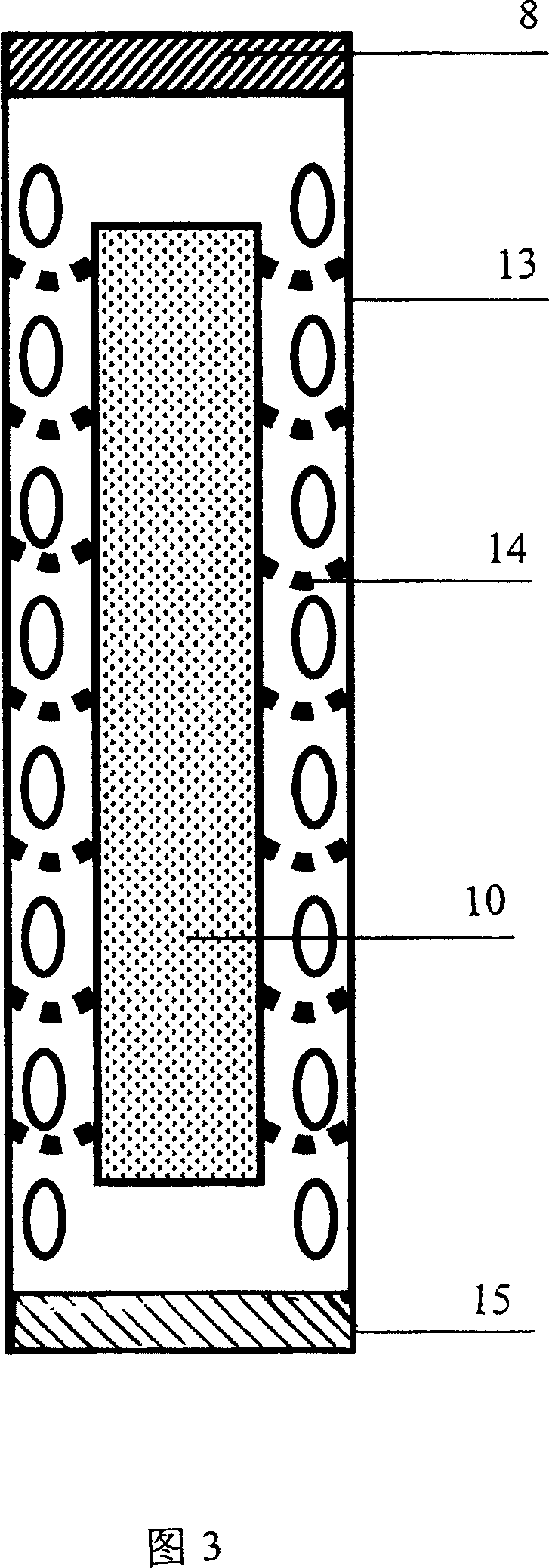

The invention discloses a long-stroke fast tool servo device. The long-stroke fast tool servo device comprises a machine frame, a piezoelectric ceramic driver which is arranged on the machine frame and can achieve axial telescoping, an input block which abuts against the tail end of the piezoelectric ceramic driver and is driven by the piezoelectric ceramic driver to make linear movement, a tool rest used for mounting a tool, and a displacement magnification mechanism which is connected between the input block and the tool rest and used for magnifying and transferring the displacement of the piezoelectric ceramic driver to the tool rest. The overall structure of the displacement magnification mechanism is symmetrical by using the piezoelectric ceramic driver as the axis of symmetry. According to the long-stroke fast tool servo device disclosed by the invention, the piezoelectric ceramic driver is used for driving the tool to make displacement, and high displacement accuracy is guaranteed; meanwhile, the displacement of the piezoelectric ceramic driver is increased through the displacement magnification mechanism, so that the tool has a large displacement stroke; and the influence factors on the axial displacement of the tool are removed through the axisymmetric structure of the displacement magnification mechanism, and the displacement accuracy of the tool under the long-stroke condition is further improved.

Owner:GUANGDONG UNIV OF TECH

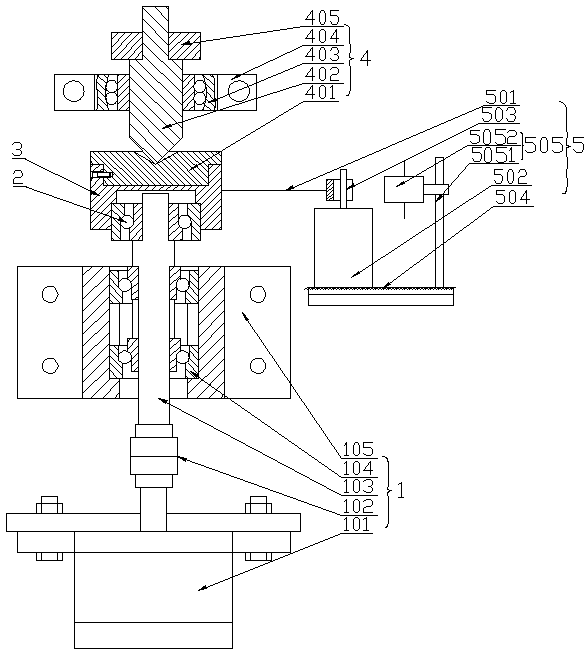

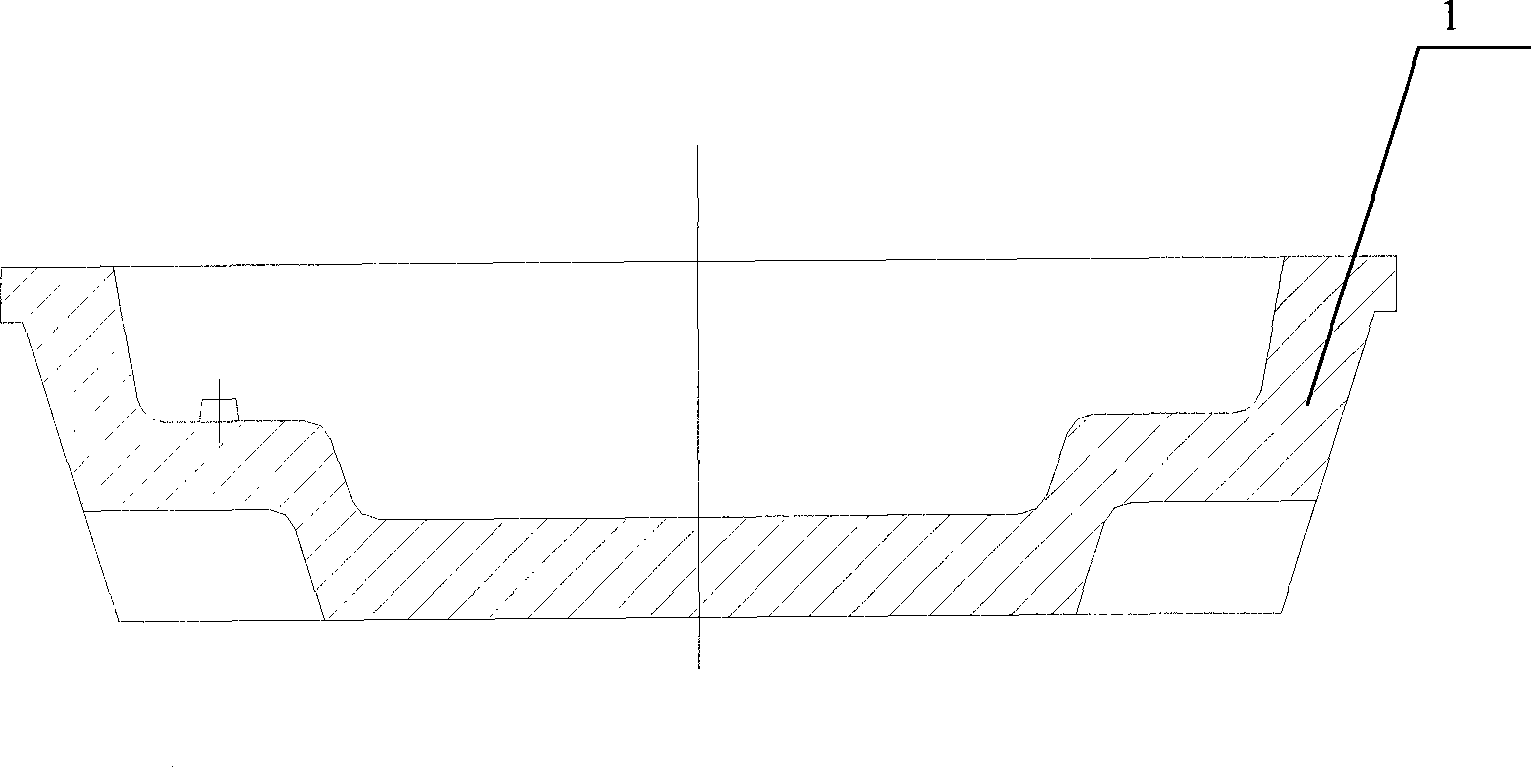

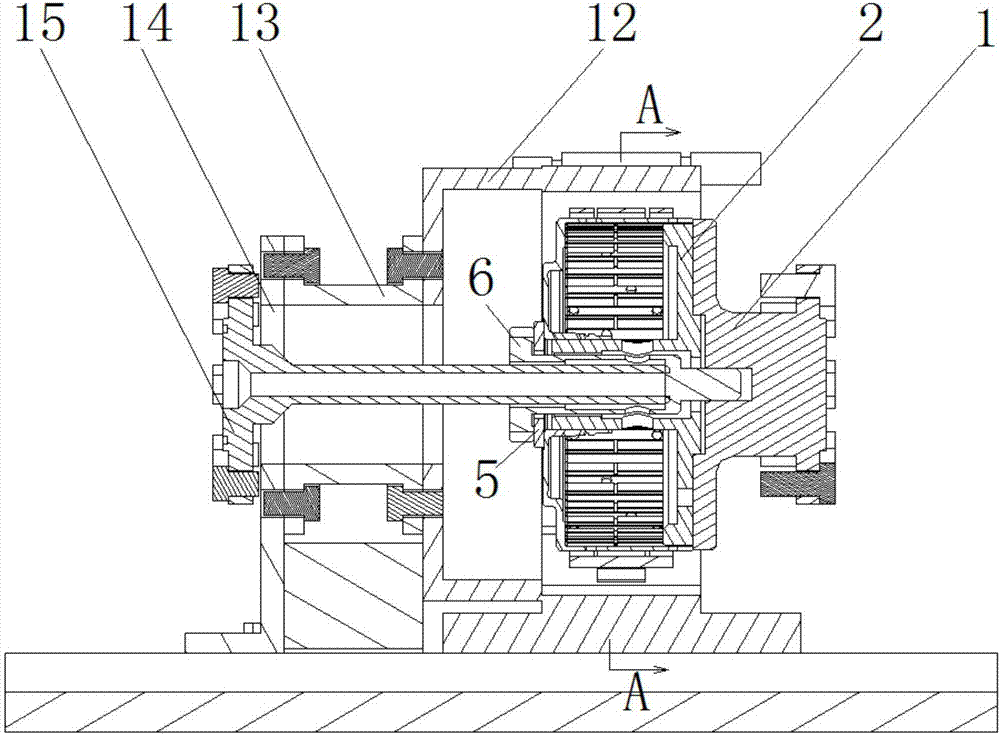

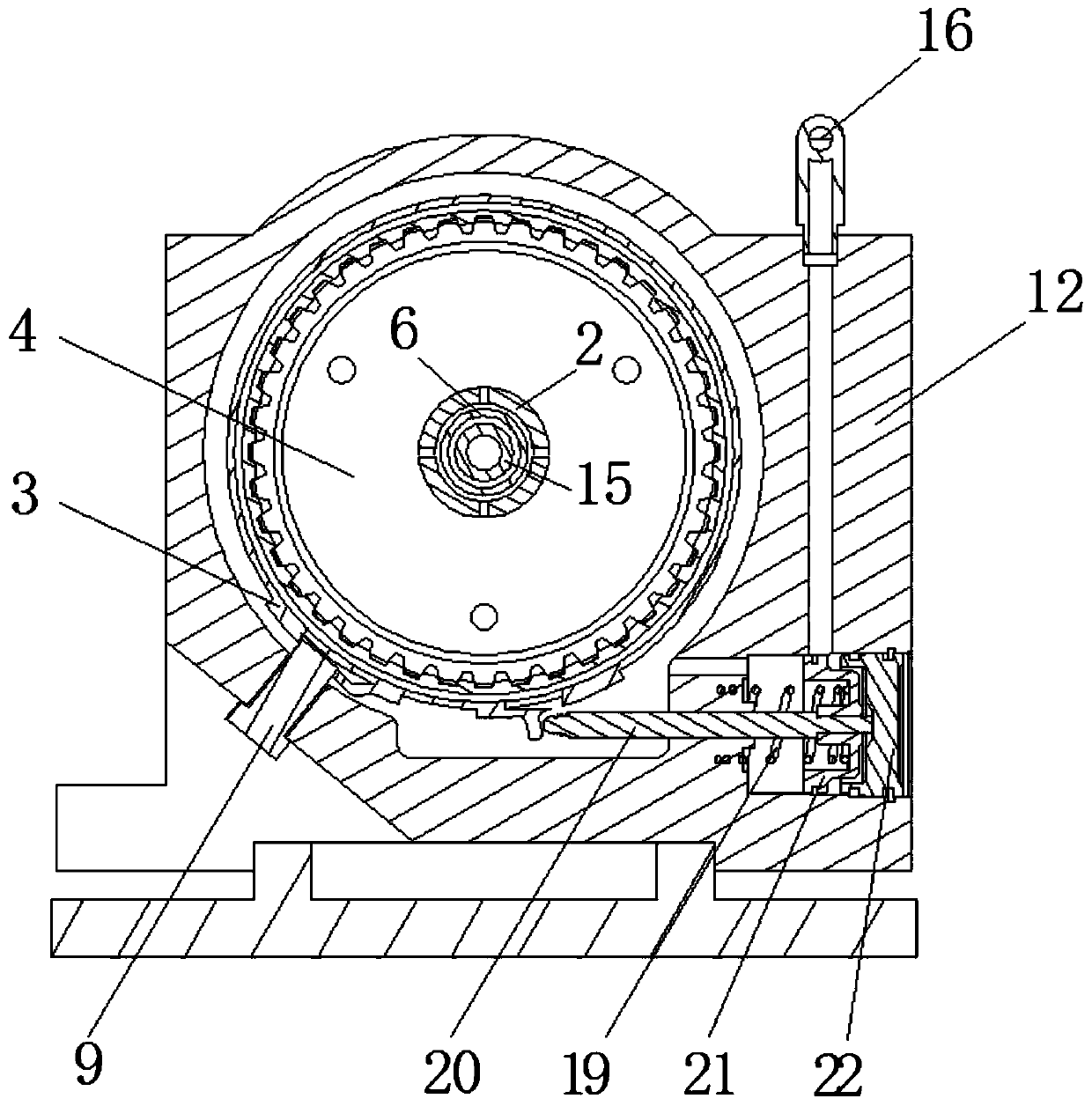

Miniature bearing friction torque measuring device

InactiveCN108918000AWith self-aligning functionNo overturning momentMachine bearings testingForce sensorsFriction torqueEngineering

The invention relates to the technical field of measuring equipment, in particular to a miniature bearing measuring device, comprising a power mechanism, wherein the output shaft of the power mechanism is connected with the inner ring of a bearing to be tested, the outer ring of the bearing to be tested is connected with a loading ring, the loading ring is provide with a loading mechanism, a forcemeasuring mechanism is arranged on the side of the loading ring, the force measuring mechanism comprises a force applying rod connected to the side of the loading ring at the left end, and the rightend of the force applying rod is connected with a sensor. In the invention, the loading part has a self-aligning function to well ensure pure axial loading without generating an overturning moment with respect to the axis; the position of the sensor increases a homing device of the electromagnet, so that the force sensor can automatically zero, and the problem that it is impossible for self-zeroing or it is too difficult for manual zeroing caused by too sensitive sensor and small range of the sensor; the installation and replacement are convenient and fast, and the loading block can be disassembled and replaced without affecting the test of the test bearing.

Owner:HENAN UNIV OF SCI & TECH

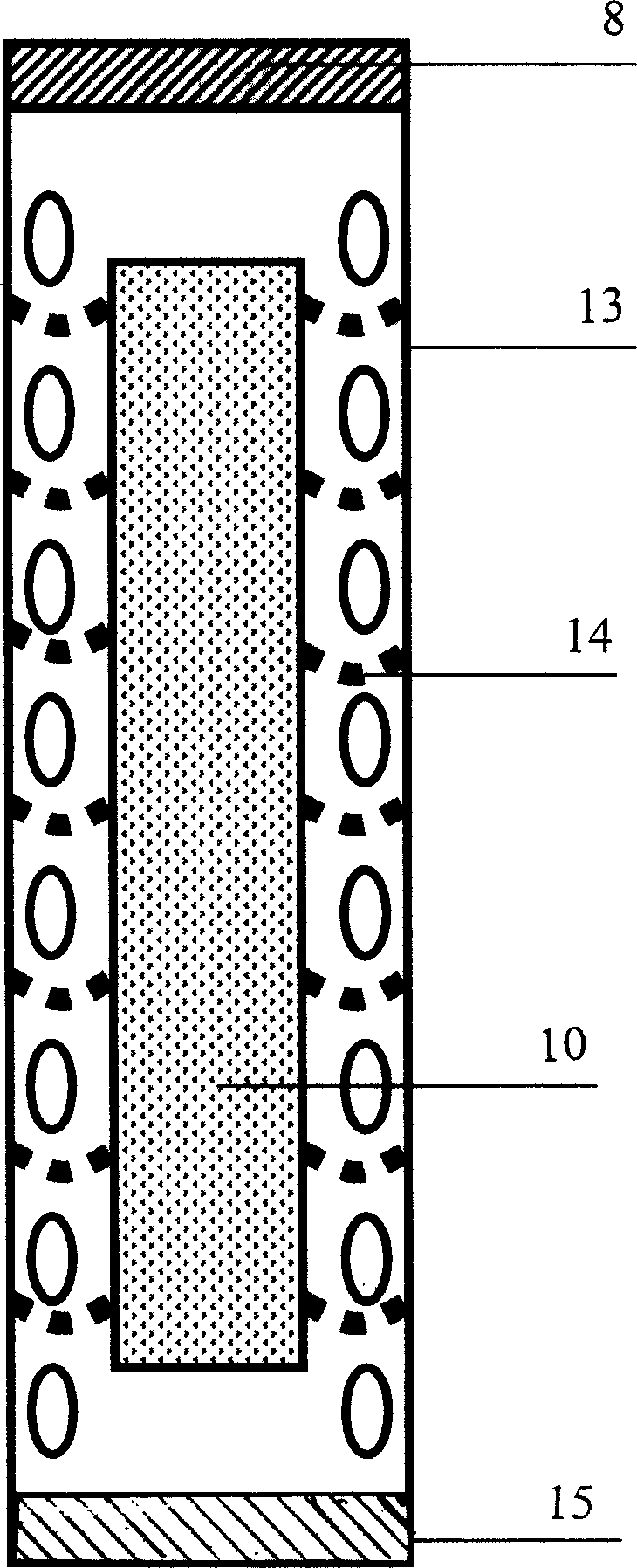

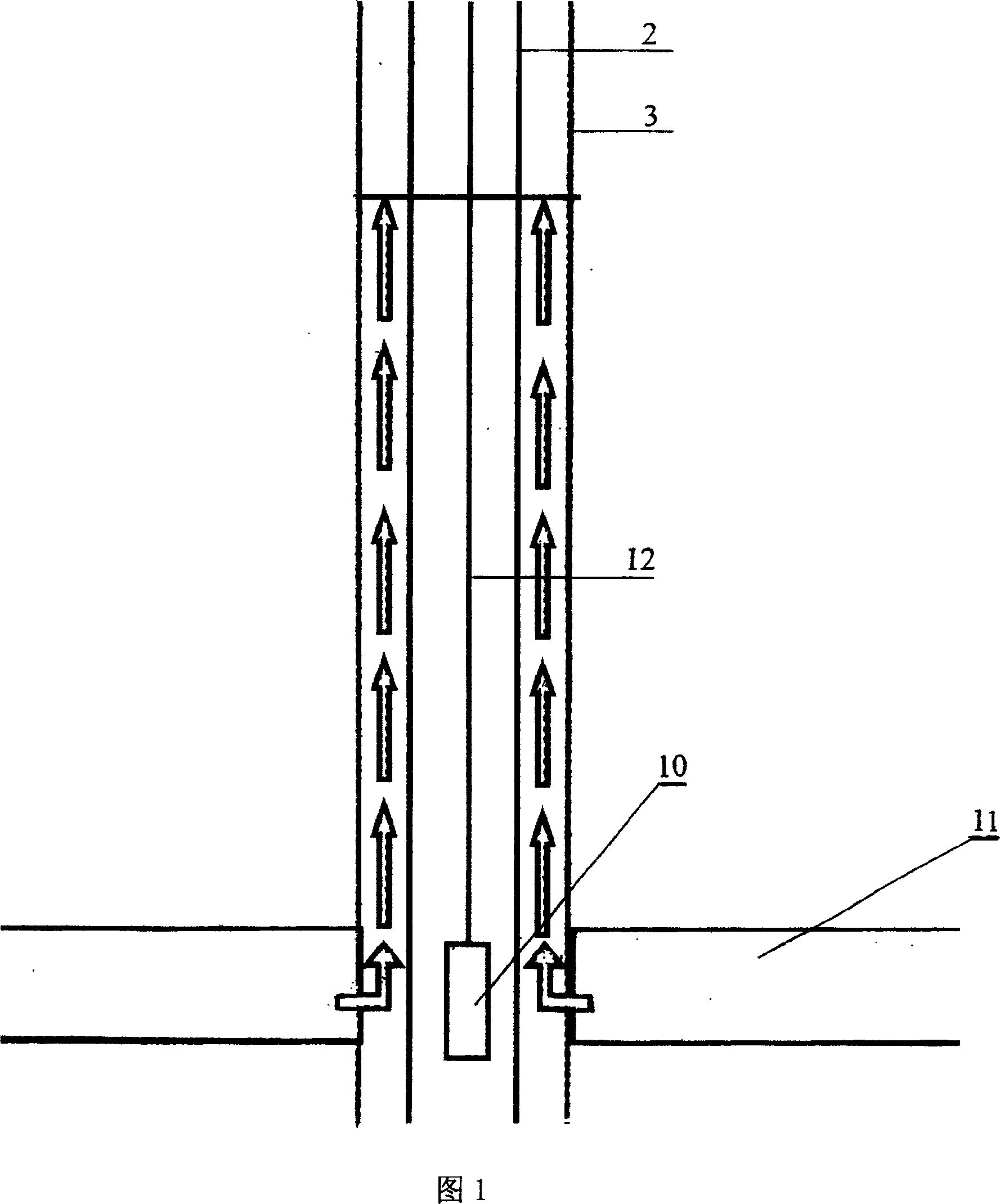

Casting method and device for ingot metal

ActiveCN101428334ADelay surface curing timeAvoid the problem of shrinkage cavityIngotZinc based alloy

The invention relates to a casting method and a device for ingot metal such as aluminum, silver, zinc and zinc-based alloy ingot. The invention adopts the method that the molten metal is cast into an ingot mold at first, then at least one surface of the ingot is heated and insulated during the solidification process, to ensure that the cooling speed thereof is greatly reduced and less than that of the other surfaces of the ingot, and the heating is not stopped until the volume of the molten metal in the center of the ingot during the cold shrinkage process is fully compensated by the molten metal on the surface. The device comprises a casting mechanism and a die, the die adopts a vessel with an opening, an insulating cover for covering the opening is also arranged on the die, and a heating device is arranged in the insulating cover. The invention can be used for ingot metal such as aluminum, silver, zinc ingot, zinc-based alloy ingot and the like cast by the die with the opening. The invention ensures that the volume of the surface can be compensated till the volume everywhere in the ingot metal is completely filled and shrunk through delaying the hardening time of one surface of the ingot metal; therefore, the influencing factors of formation of the internal shrinkage hole are radically eliminated, and the effect of eliminating the internal shrinkage hole is realized.

Owner:ZHUZHOU SMELTER GRP

Fault range finding method of power distribution network based on voltage distribution principle

ActiveCN109283430AEliminate the effects ofEliminate influencing factorsFault location by conductor typesInformation technology support systemFault coverageDistribution grid

The invention discloses a fault range finding method of a power distribution network based on a voltage distribution principle. According to the method, a PMU is used to obtain line state informationin real time, a fault line is determined by calculating and comparing the head-end line voltages in the same branch point after a fault, and a fault is located in the fault line accurately via the voltage distribution principle. Branch influencing factors in the traditional power distribution network fault locating method can be eliminated, and the fault can be located rapidly and accurately; fault range finding is realized by measurement in the two ends, influence of a transitional resistor is eliminated principally, and compared with a single-end measurement method, the range finding precision is higher, measurement is not influenced by the fault type, it is not required to mount the PMU in the two ends, cost of equipment is reduced, and the application prospect is better; and the methodcan be used to realize fault range finding rapidly and effectively, and the operational reliability, safety and flexibility of the system can be improved greatly.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +2

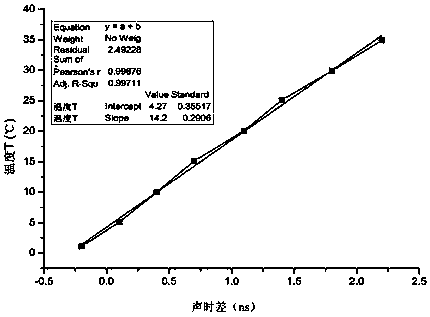

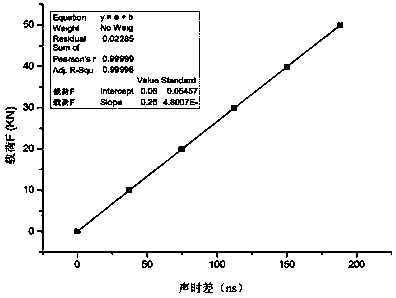

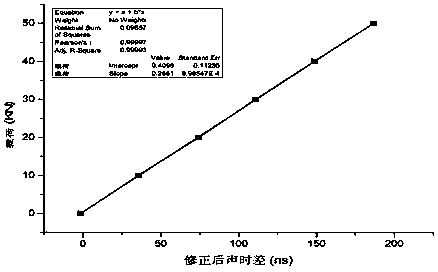

Method for calibrating pre-tightening force of external thread fastener with sensor

ActiveCN110530571ASimplify the calibration processFew parametersForce/torque/work measurement apparatus calibration/testingEngineeringFlight time

The invention provides a method for calibrating a pre-tightening force of an external thread fastener with a sensor. The method comprises the following steps: carrying out temperature correction on each ultrasonic flight time delta tnact' by using a reference temperature; establishing a function fitting relation between an acoustic time difference delta tnkorr'-delta t0korr after temperature correction and different loads Fn and acquiring a fitting equation of a pre-tightening force F relative to the acoustic time difference after temperature correction. Therefore, a measurement result with high reliability can be obtained during measurement.

Owner:AEROSPACE PRECISION PROD INC LTD

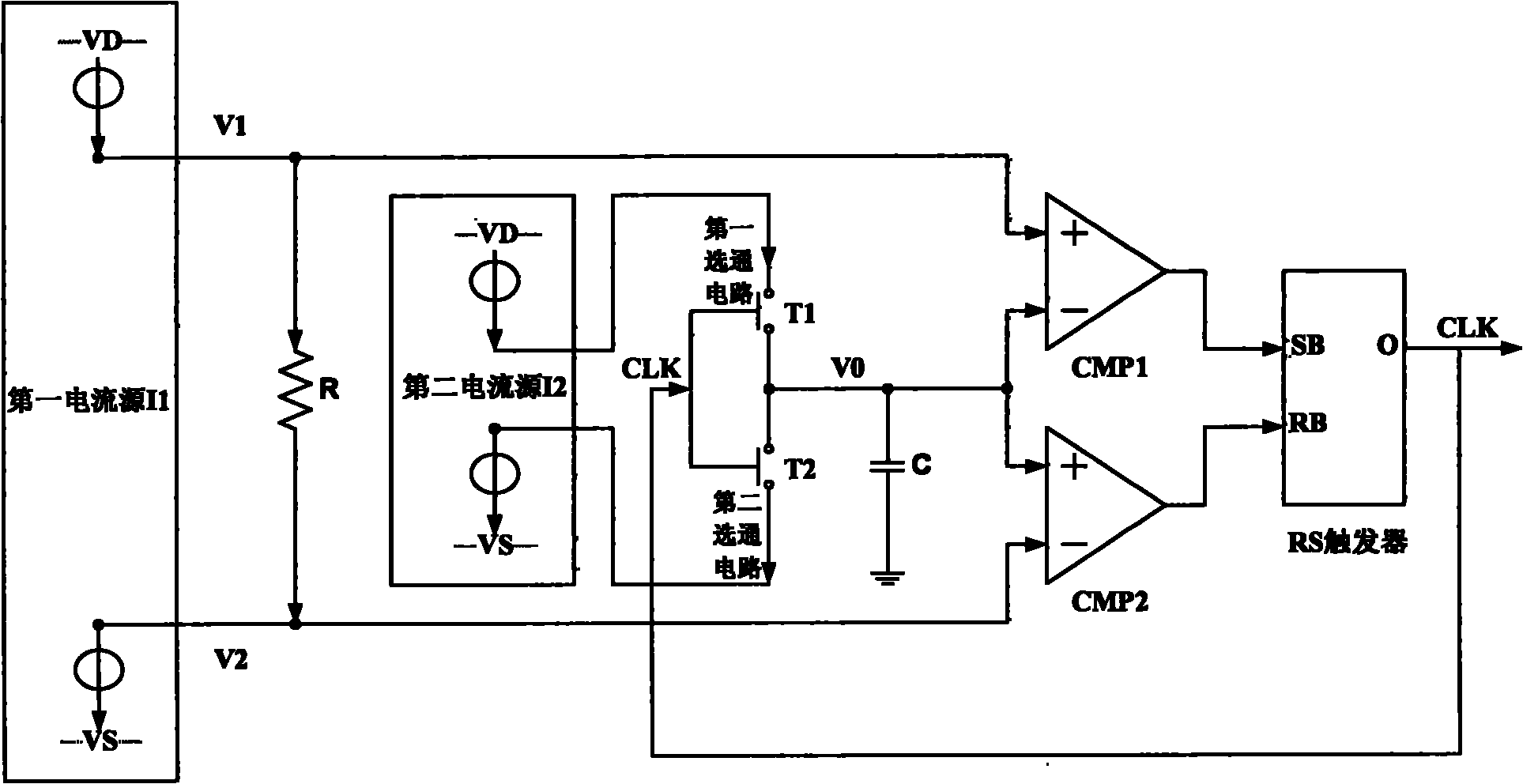

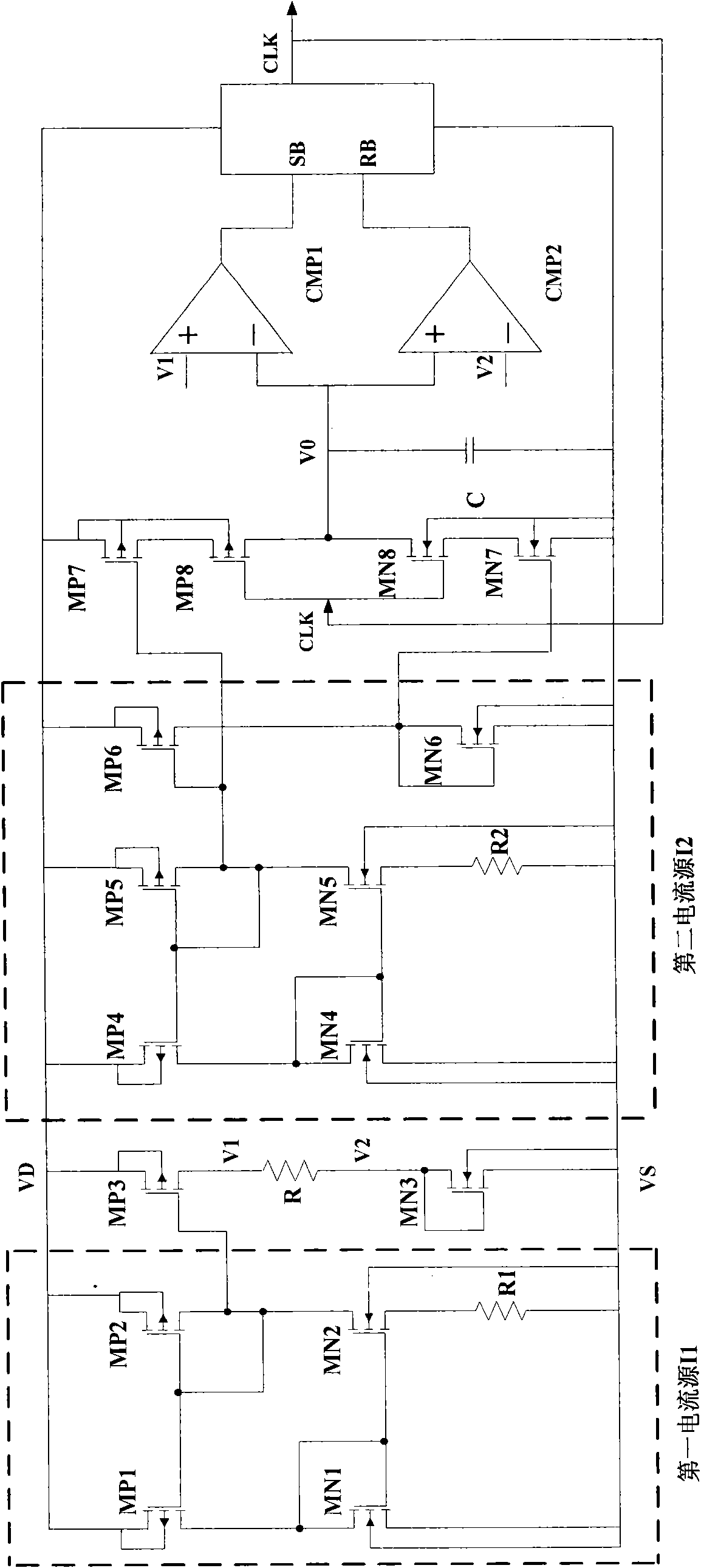

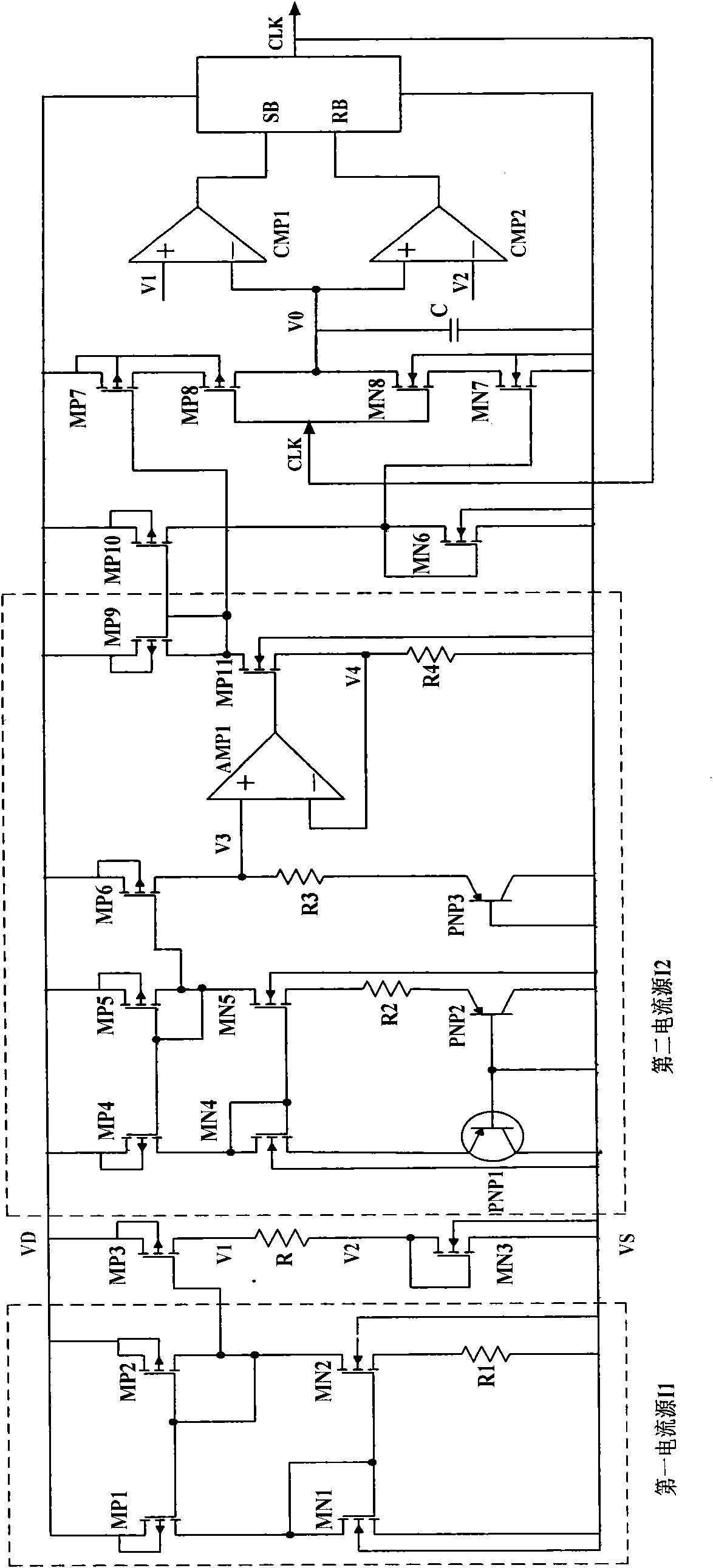

Clock generating circuit

InactiveCN101997521ASimple structureSmall process deviationElectric pulse generator circuitsCapacitancePower flow

The invention discloses a clock generating circuit. The clock generating circuit comprises a first current source, a resistor connected with the first current source, a second current source, a first gating circuit connected with the second current source, a second gating circuit connected with the second current source, a capacitor connected with the first gating circuit and the second gating circuit, a first comparator connected with the first current source and the capacitor, a second comparator connected with the first current source and the capacitor, and a remote sensing (RS) trigger connected with the first comparator and the second comparator, wherein the RS trigger outputs a clock signal to an input control terminal of the first gating circuit and an input control terminal of thesecond gating circuit; when the first gating circuit is gated, the second current source charges the capacitor; and when the second gating circuit is gated, the second current source discharges the capacitor. The clock generating circuit has a simple structure, low process variation and relatively low cost and improves the clock precision to the maximum degree.

Owner:CHENGDU MINGXINGXINGTONG TECH CO LTD

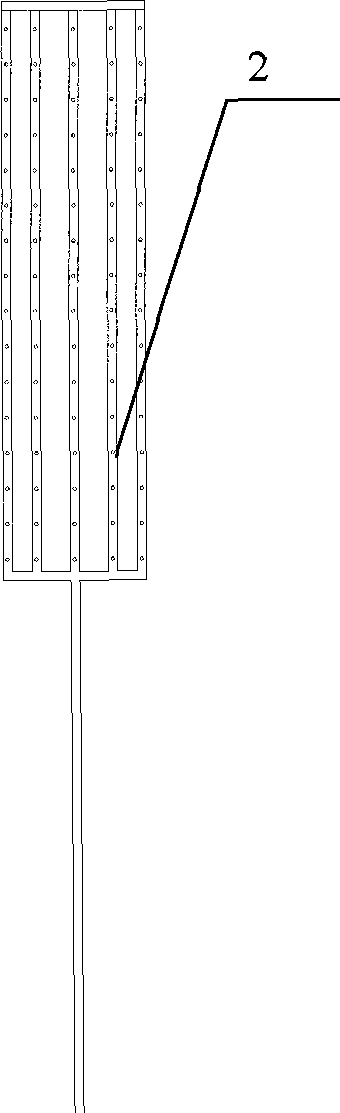

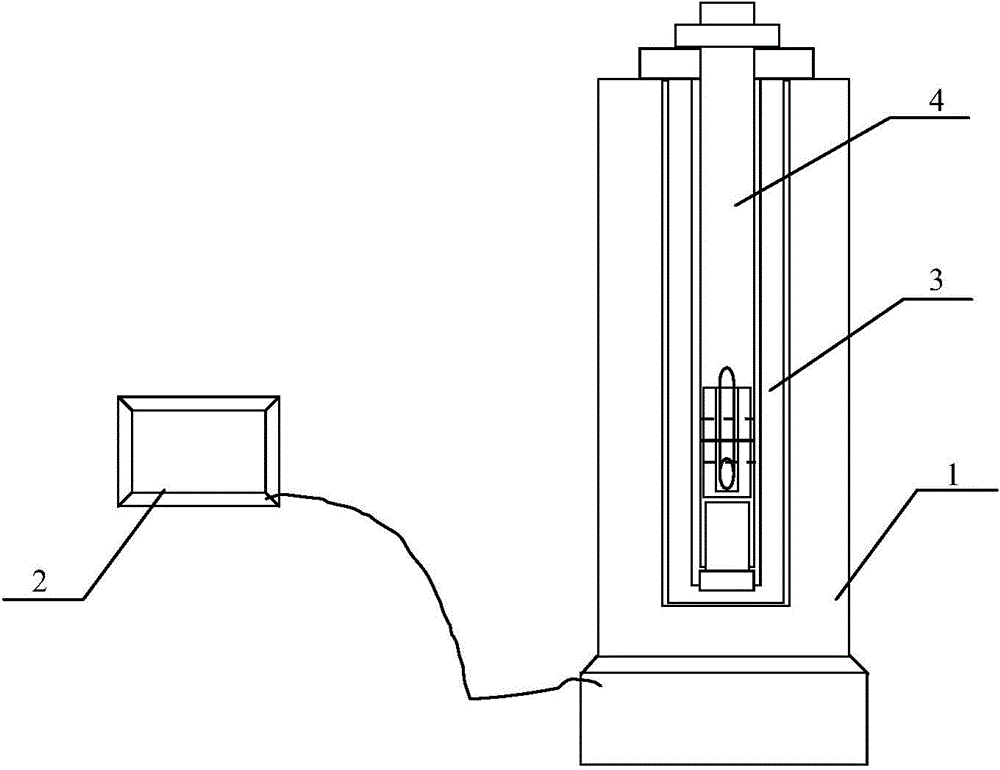

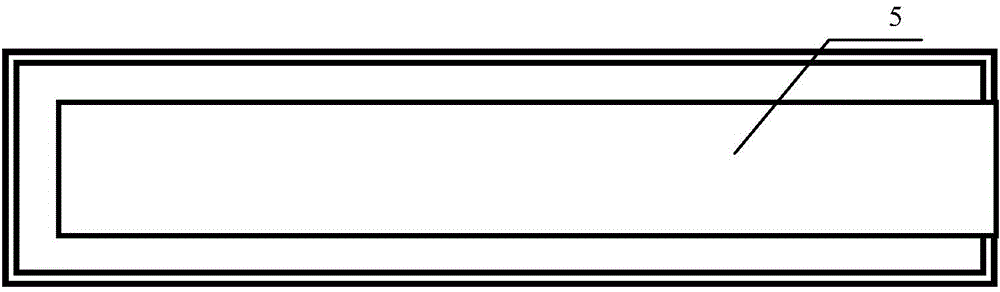

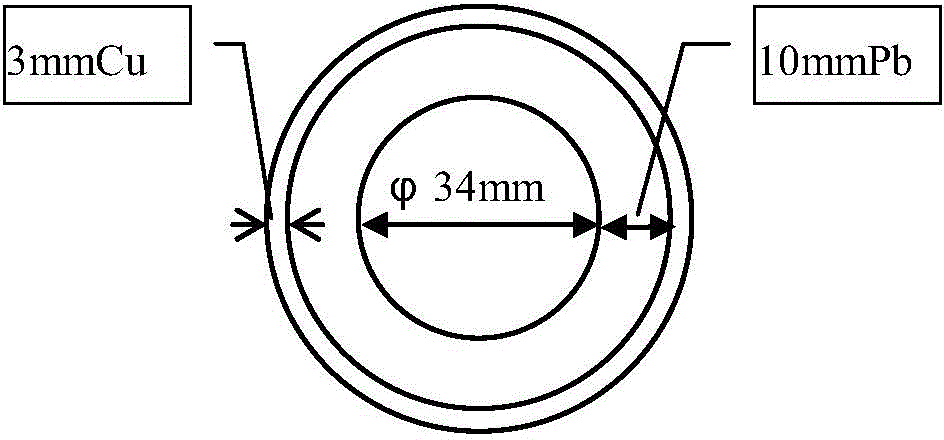

Solid radium source field calibrating device and method

InactiveCN104808238AEliminate factors affecting field environmental conditionsEliminate the effects ofX/gamma/cosmic radiation measurmentIonization chamberSource field

The invention belongs to the technical field of nuclear and radiation environment monitor and measurement and particularly relates to a solid radium source field calibrating device and method. The device comprises a well-type ionization chamber (1), an electrometer (2), a low-energy gamma ray shielding device (3) and a source measurement rack (4). The method comprises the steps of determining of the optimal working area of the well-type ionization chamber, monitored measurement of a monitored source, field testing preparation, radium content calculation and the like. The application of the solid radium source field calibrating device to radioactive source calibration of uranium exploration changes the tracing manner of inspection of traditional radioactive sources and eliminates potential risks of movement and transportation of radioactive source tracing. The solid radium source field calibrating method achieves field calibration of solid radium sources.

Owner:核工业航测遥感中心

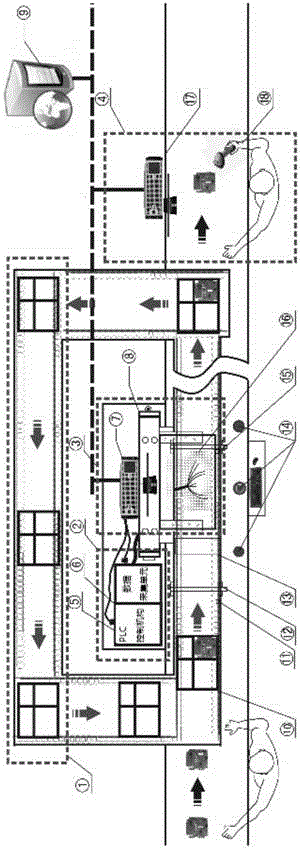

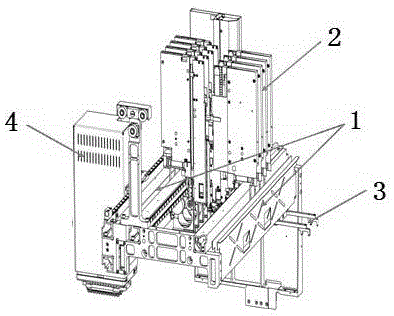

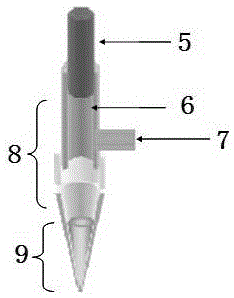

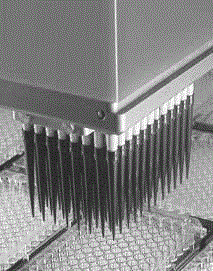

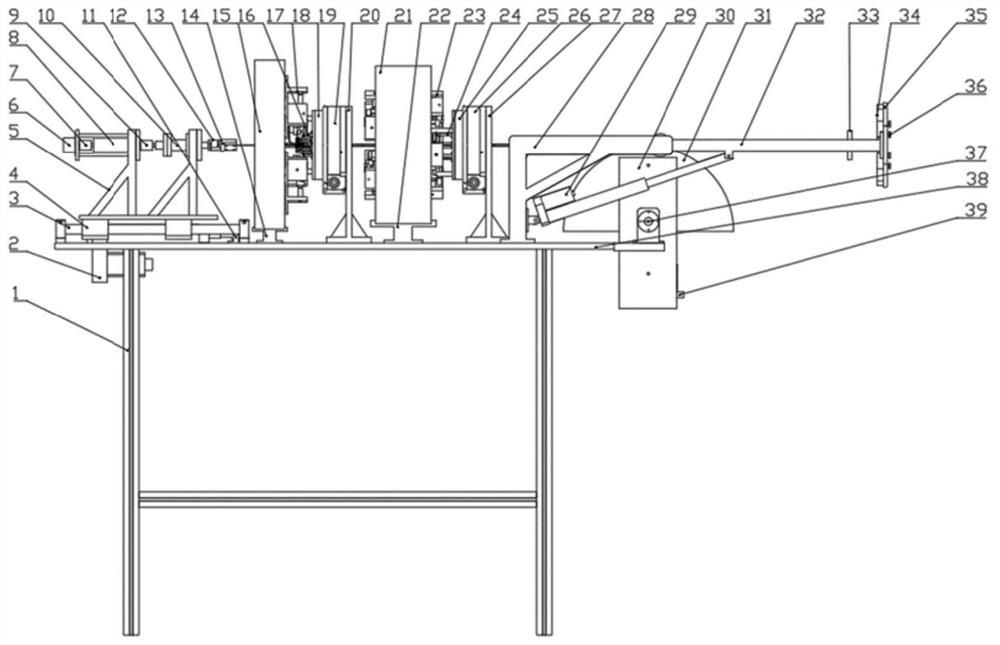

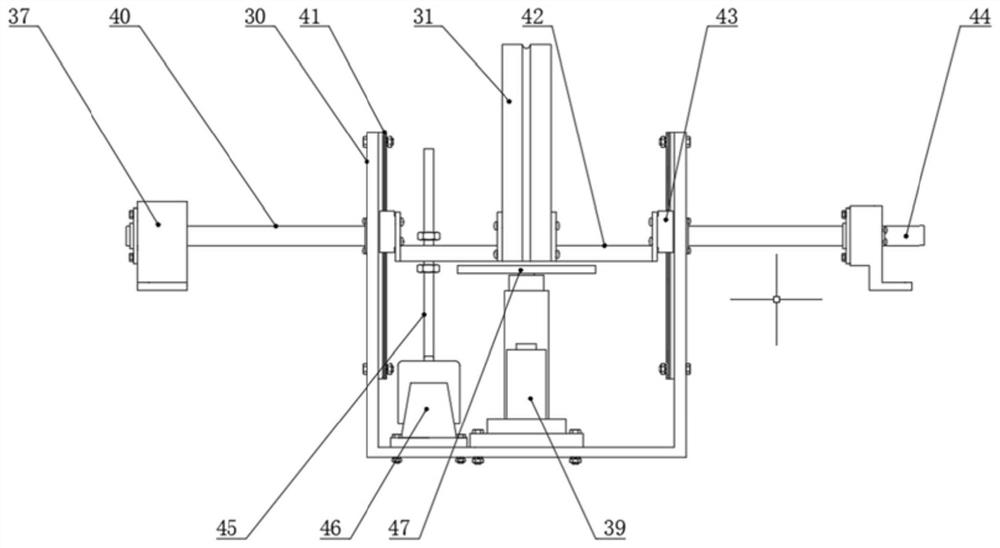

PCBA testing system

The invention relates to a PCBA testing system. The PCBA testing system comprises a chain rail part, a pneumatic control part and a testing part, wherein the chain rail part is used for transferring a PCBA to be tested so that the PCBA to be tested can be conveyed to a testing station; the pneumatic control part is used for controlling a testing probe board to be close to or away from the PCBA to be tested on the testing station so that testing probes installed on the testing probe board can be used for detecting the PCBA to be tested; and the testing part is connected with the testing probe board and used for testing the PCBA to be tested. By the adoption of the PCBA testing system, PCBA testing efficiency can be improved and testing cost can be reduced.

Owner:SHENZHEN GOLDEN SQUARE TECH

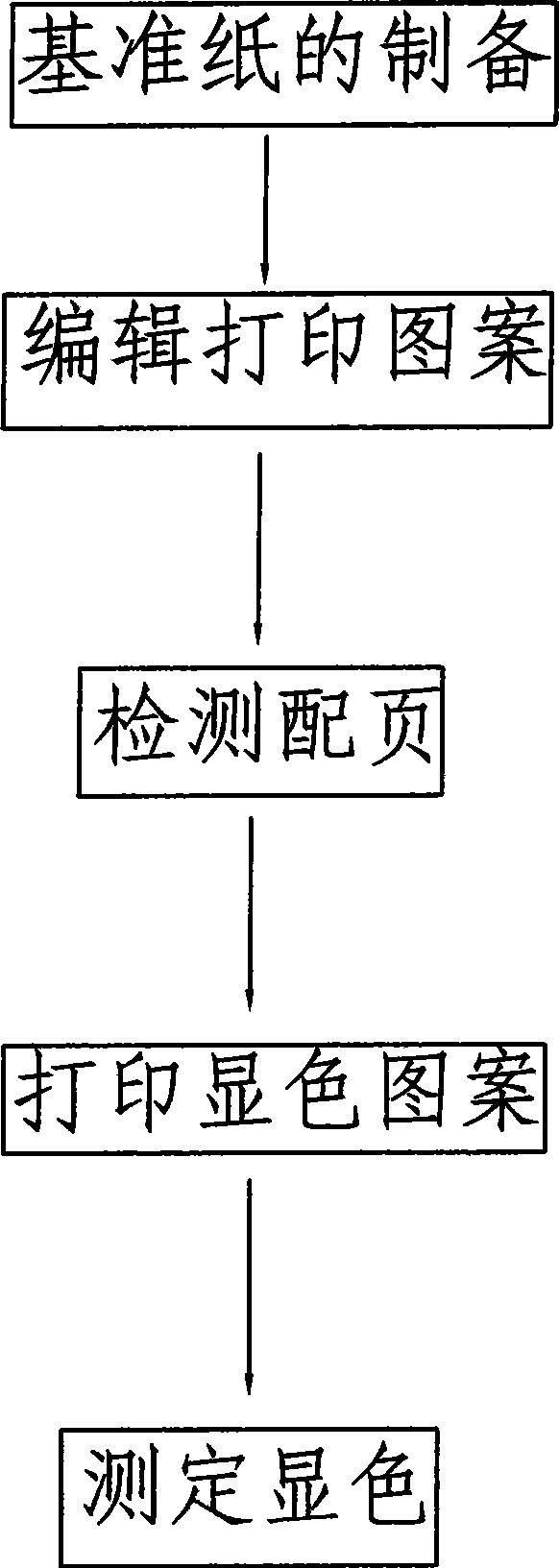

Method for detecting non-carbon carbon paper CB surface and CF surface colour development by reference paper

ActiveCN101373183AEnsure the true level of color renderingSimple processDuplicating using pressureMaterial analysisInstabilityComputer science

The invention relates to the technical field of NCR (no carbon required)-paper, and in particular to a method of using reference paper for testing chromogenesis on the CB surface and the CF surface of the NCR-paper. The method comprises the following steps: reference CB paper and reference CF paper are prepared; a pattern is edited and printed; collating is tested; and chromogenesis is tested and determined. The method is characterized by simple procedure and easy operation. Moreover, the method adopts the fixed reference CB paper and the fixed reference CF paper instead of CB paper and CF paper in production. Compared with the prior approach of taking random samples in the production field for combined inspection, the method eliminates the instability of test paper, and ensures that the real chromogenic capacity of the test paper can be determined and the test result is reliable. According to the result of the chromogenesis test, the fine quality fluctuation can be identified in time, the applied quantity is precisely controlled to avoid insufficiency or surplus, and other factors that affect the test are eliminated, thereby ensuring product quality, reducing manufacturing cost and effectively guiding production.

Owner:GUANGDONG QIAOSHENG ANTI COUNTERFEITING MATERIALS CO LTD

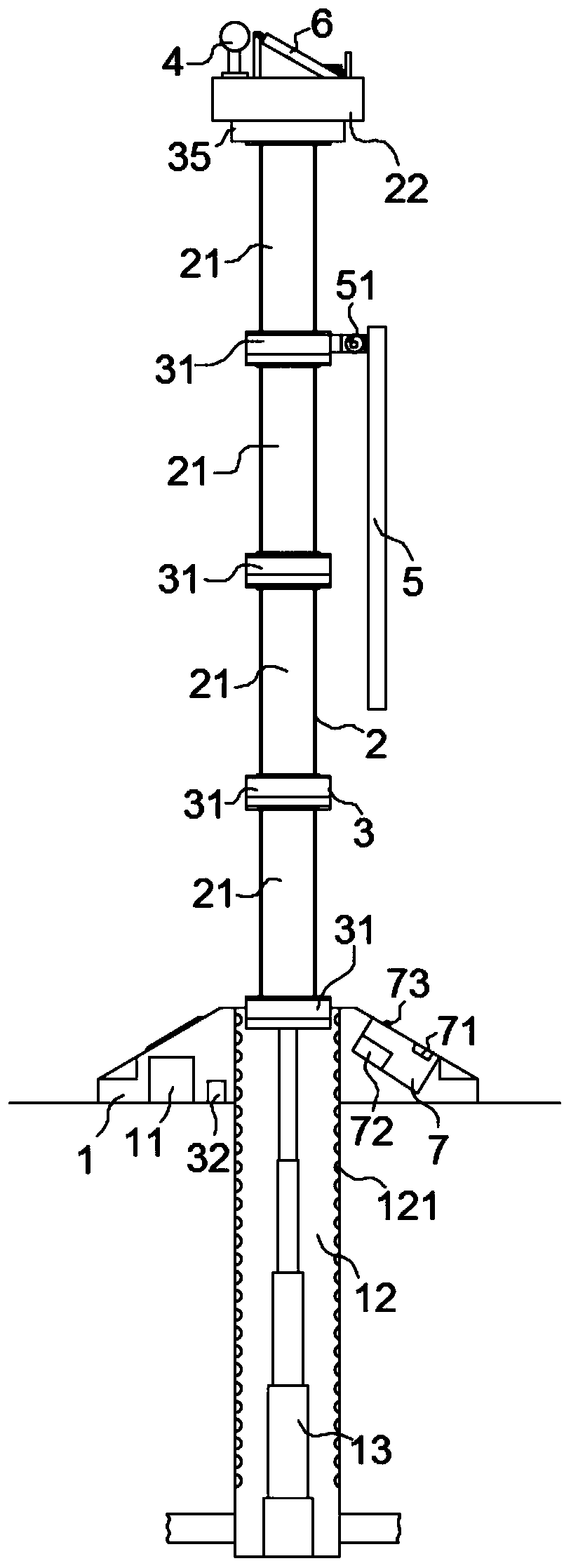

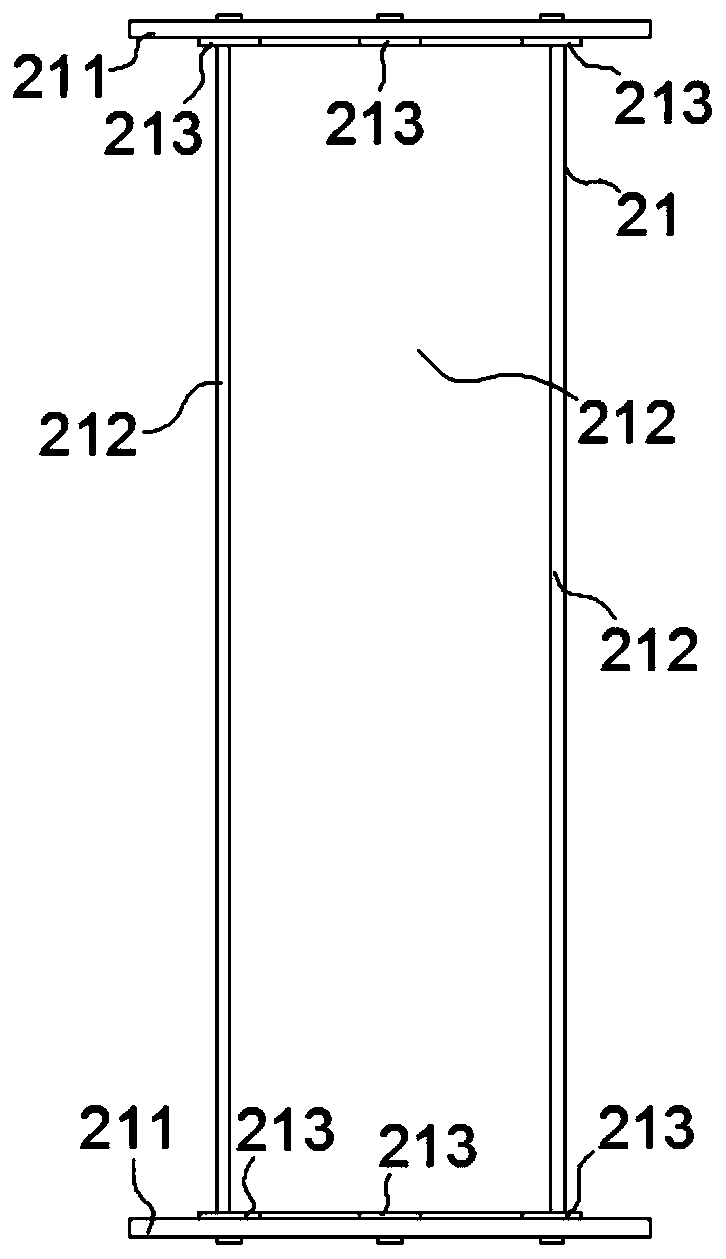

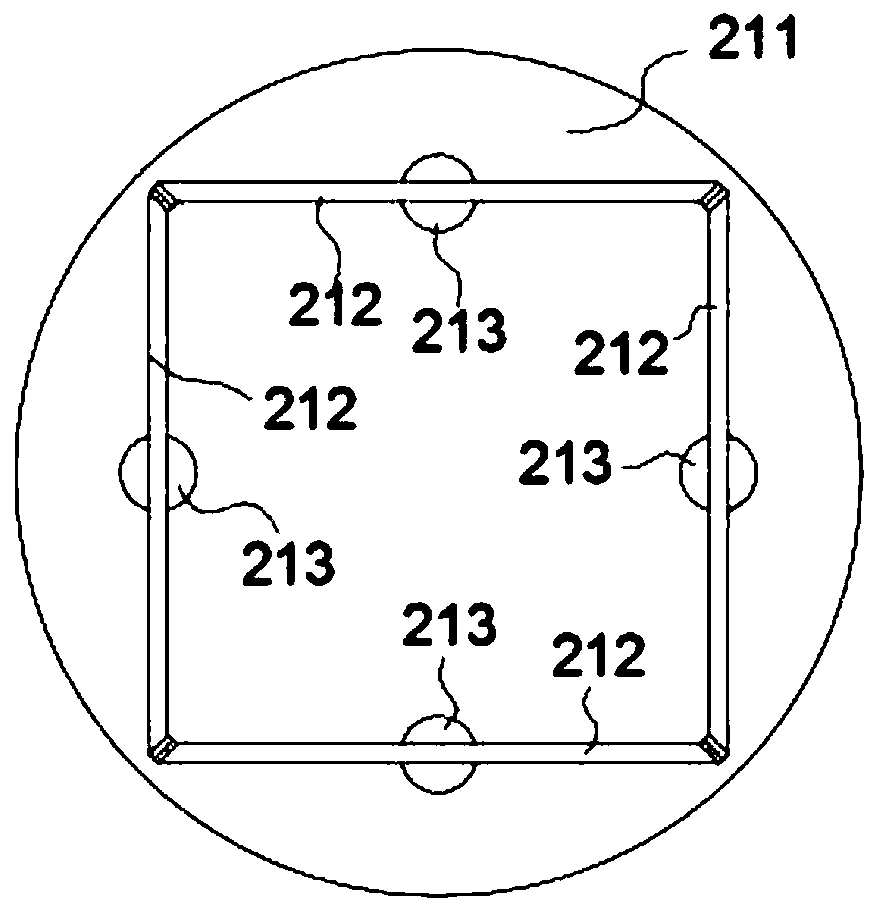

Anchor drilling jig provided with rod-protection mechanical hand and used for coal mine

ActiveCN111997667AExtend your lifePrevent stick throwDrilling rodsDrilling casingsRobot handStructural engineering

The invention belongs to anchor rod support equipment, and particularly relates to an anchor drilling jig provided with a rod-protection mechanical hand and used for a coal mine. A sliding frame assembly is mounted on a frame assembly. A long feeding oil cylinder is mounted at the bottom of the frame assembly. A cylinder barrel lug base of the long feeding oil cylinder is connected with a long feeding oil cylinder fixing lug base of the frame assembly. A cylinder rod lug base of the long feeding oil cylinder is connected with a top plate of the sliding frame assembly. A guide connecting platewhich can slide relatively is mounted on the sliding frame assembly and is fixedly connected with a drilling box. A top rod back-hooking device which can turn a mechanical paw is fixed to one side ofthe drilling box. A mechanical hand protection arm and the mechanical paw are connected to the frame assembly. One end of a chain transmission device is connected with the guide connecting plate, andthe other end of the chain transmission device is connected with the sliding frame assembly. The chain transmission device is wound on a short feeding oil cylinder through a sliding wheel assembly, and the guide connecting plate is improved by multiple times through a sliding wheel device composed of a short feeding oil cylinder stretching chain drive device and the guide connecting plate.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

Linkage wind-resistant multifunctional intelligent rod

InactiveCN110850783AReduce windLower the altitudeProgramme controlBatteries circuit arrangementsWind runElectric machine

The invention discloses a linkage wind-resistant multifunctional intelligent rod, which mainly comprises a base, an intelligent rod body, an intelligent linkage device, a weather detector and an information publishing board, wherein the intelligent rod body comprises a plurality of groups of wind-sheltering adjusting rods and a top cover; a storage battery is arranged in the base, and a deep groove is formed in the center of the base; the wind-sheltering adjusting rods are connected with the bottom part of the deep groove by means of a lifting motor; each wind-sheltering adjusting rod is composed of an upper loading piece, a lower loading piece and a plurality of sets of rotating plates circumferentially arranged between them; the intelligent linkage device comprises a linkage adjusting disc and a single-chip microcomputer; the information publishing plate is arranged on one side surface of the middle linkage adjusting disc; the weather detector is arranged on the top cover of the intelligent rod body and is connected with the single-chip microcomputer; and the single-chip microcomputer is arranged inside the base. According to the linkage wind-resistant multifunctional intelligentrod, meteorological information such as wind pressure, wind speed and wind direction is obtained by means of the weather detector, and the intelligent rod body and externally-hung equipment thereof can adapt to wind change aerodynamic shapes under the condition of strong wind through meteorological monitoring and linkage control of deformation of the externally-hung equipment, thereby achieving the purpose of stable wind resistance.

Owner:深圳市深汕特别合作区智慧城市研究院有限公司

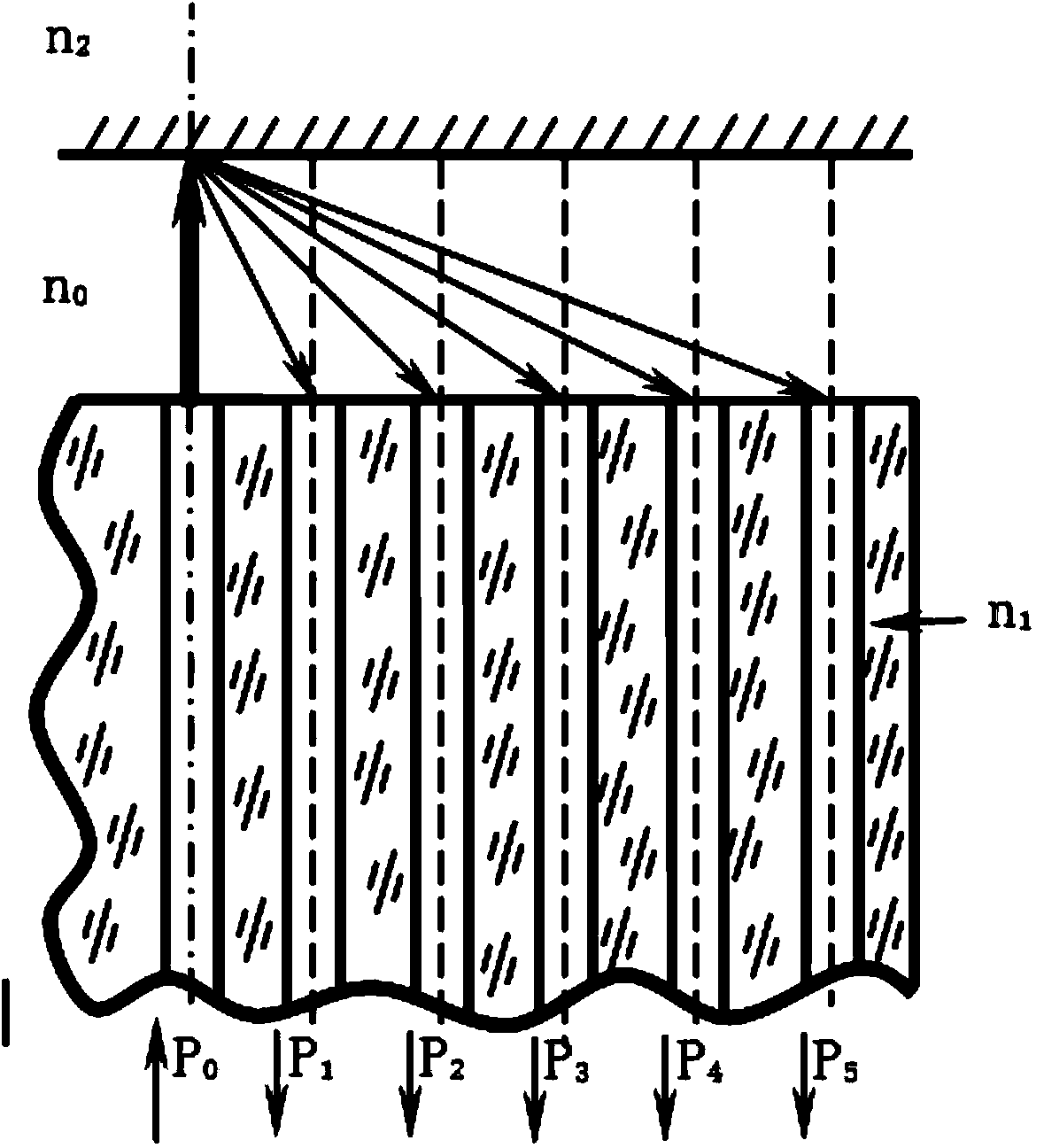

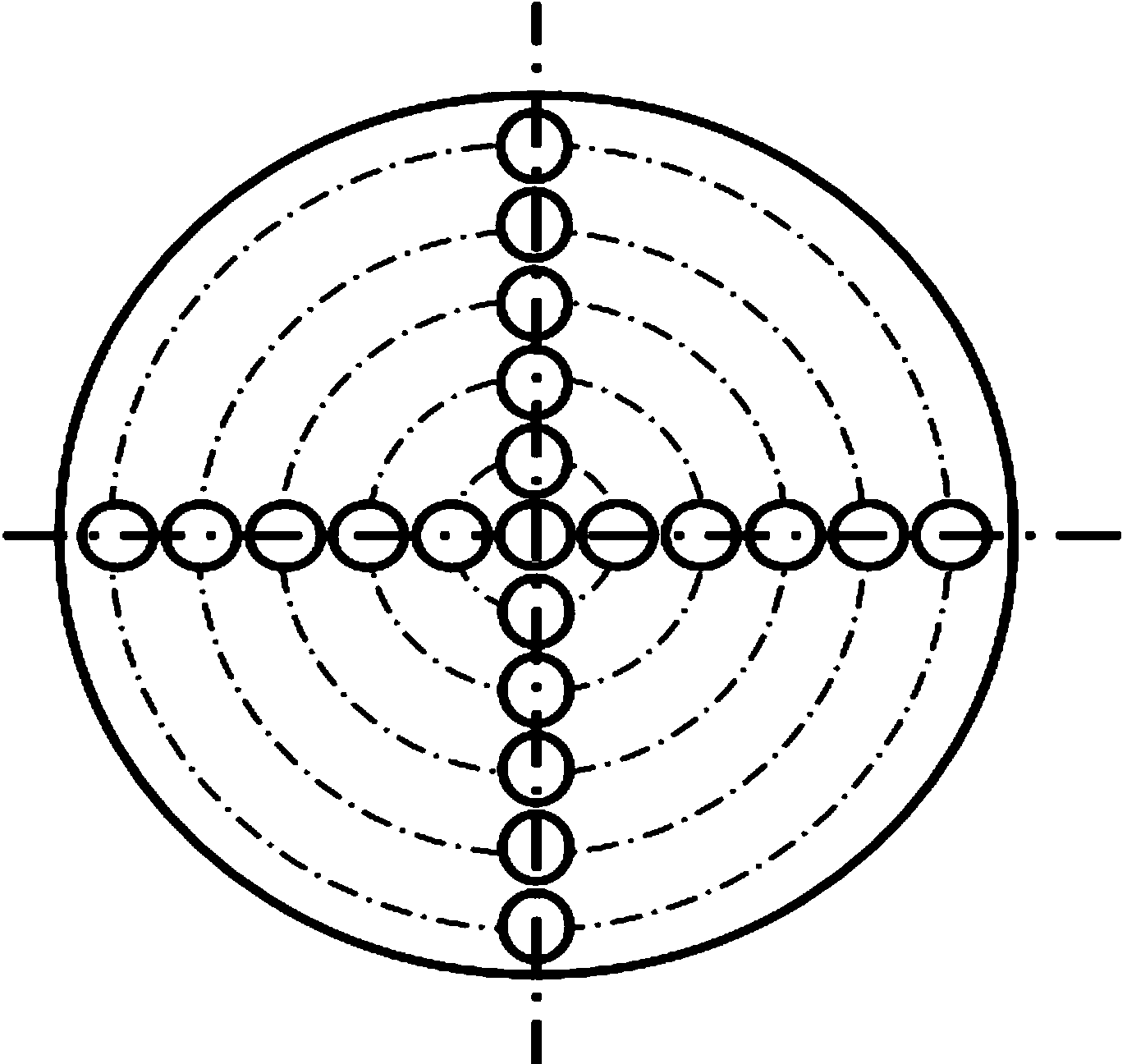

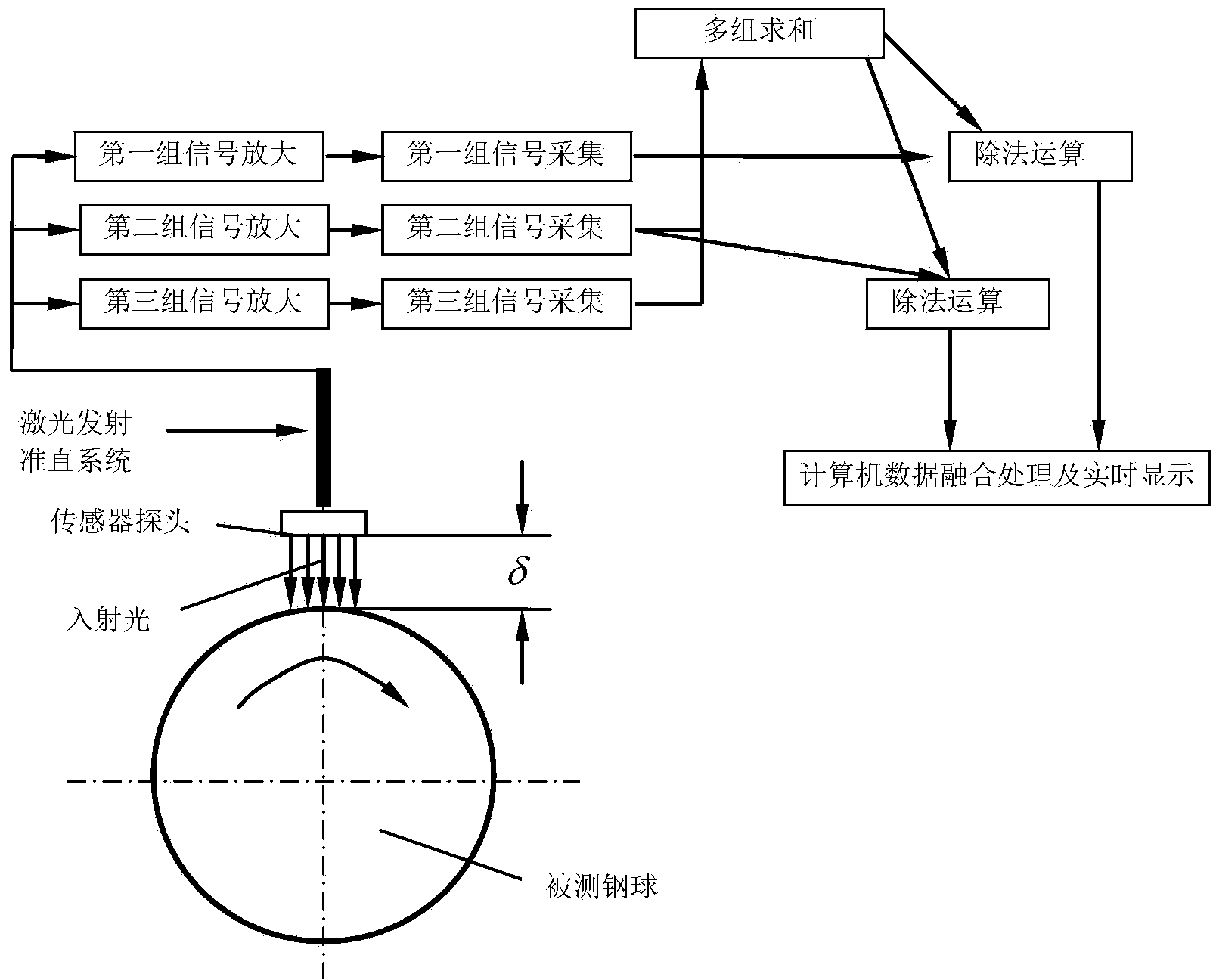

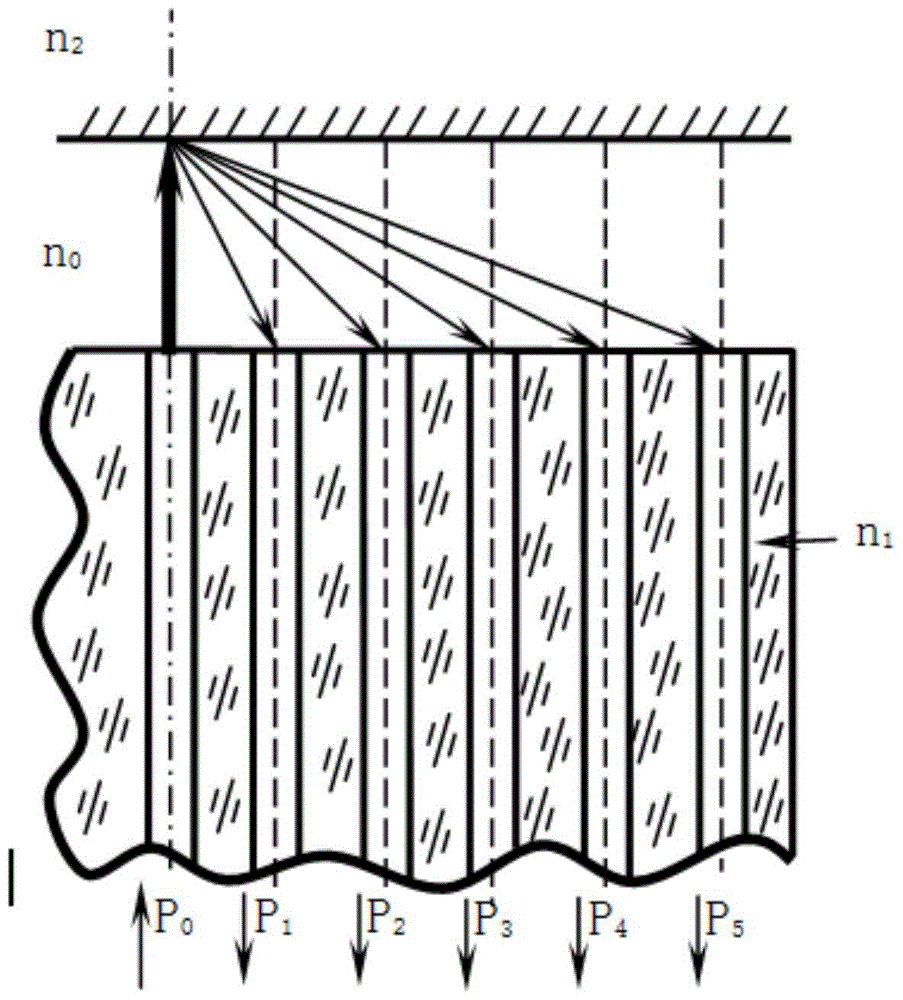

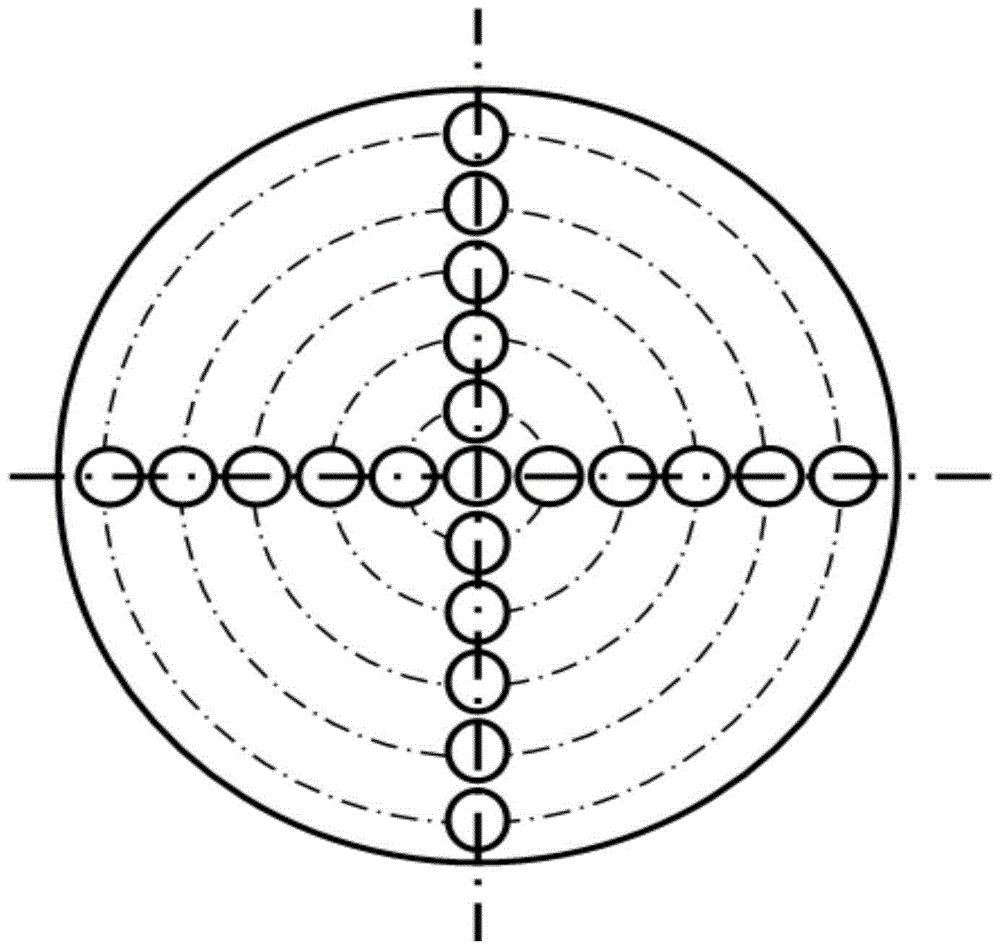

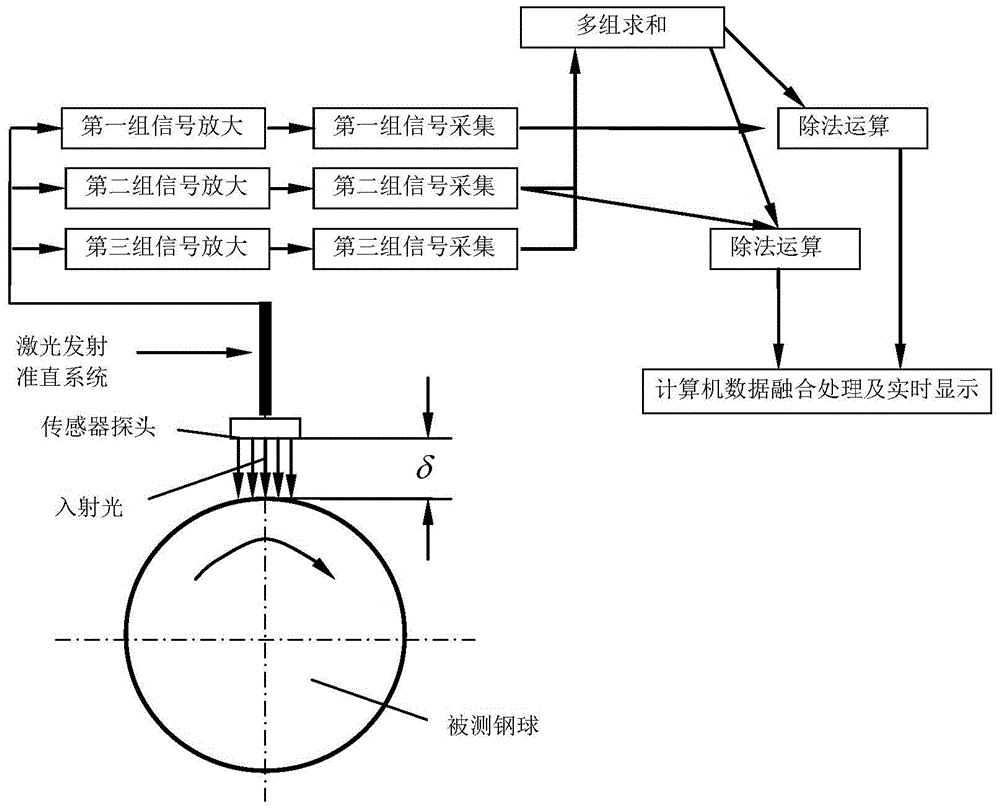

Compensation method of steel ball surface detect measuring system based on optical fiber sensing

InactiveCN103776843AEliminate influencing factorsQuick judgmentMaterial analysis by optical meansOptical power meterSteel ball

The invention particularly discloses a compensation method of a steel ball surface detect measuring system based on optical fiber sensing. The compensation method of the steel ball surface detect measuring system based on optical fiber sensing comprises the following steps: step 1, for a sensor structure that a single optical fiber transmits scattered light and a plurality of groups of optical fibers receive scattered light, measuring by an optical power meter so as to obtain detection incidence power P0 and corresponding light power P1, P2,..., and Pn received by multiple groups of optical fibers; step 2, collecting data of the light power P1, P2,..., and Pn which are obtained in the step 1 by a multi-path high-speed synchronous data collecting plate, thereby obtaining digital signals with N light intensity; summing the N groups of light intensity so as to obtain P=P1+P2+P3+...+Pn; step 3, carrying out division operation on the P, P1, P2, ..., and PN which are obtained from the step 2, that is, dividing multiple groups of received light intensity by each group of received light intensity so as to obtain specific values P / P1, P / P2, ..., and P / P(n-1), thereby obtaining the light intensity specific values when the sensor and a measured surface are oblique at different angles; step 4, establishing a function of a clearance varying along with the specific value; step 5, determining the coefficients a0, a1, a2, ..., and a(n-1); and step 6, substituting the coefficient values from the step 5 into the formula (1), thereby obtaining the accurate gap value.

Owner:UNIV OF JINAN

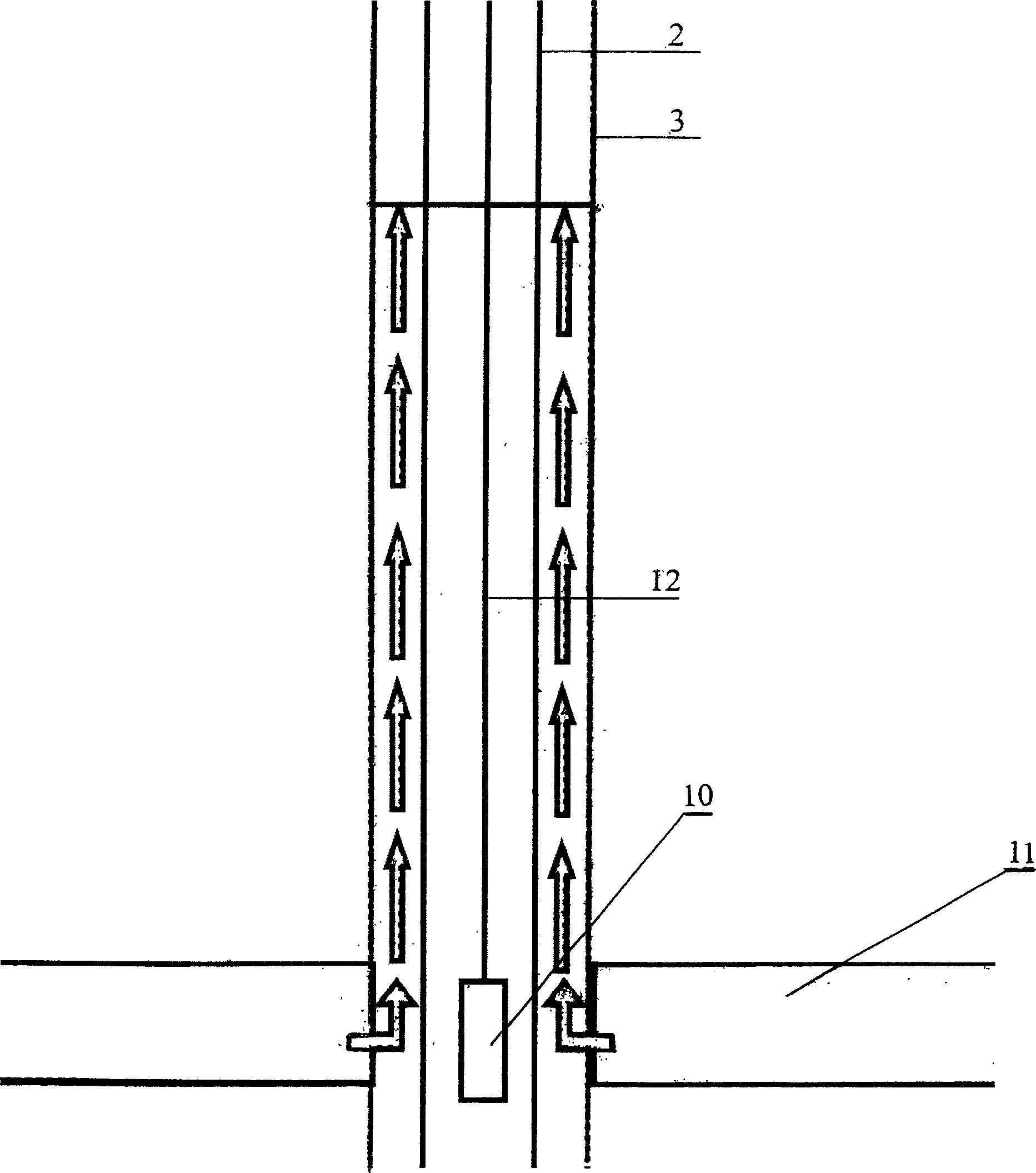

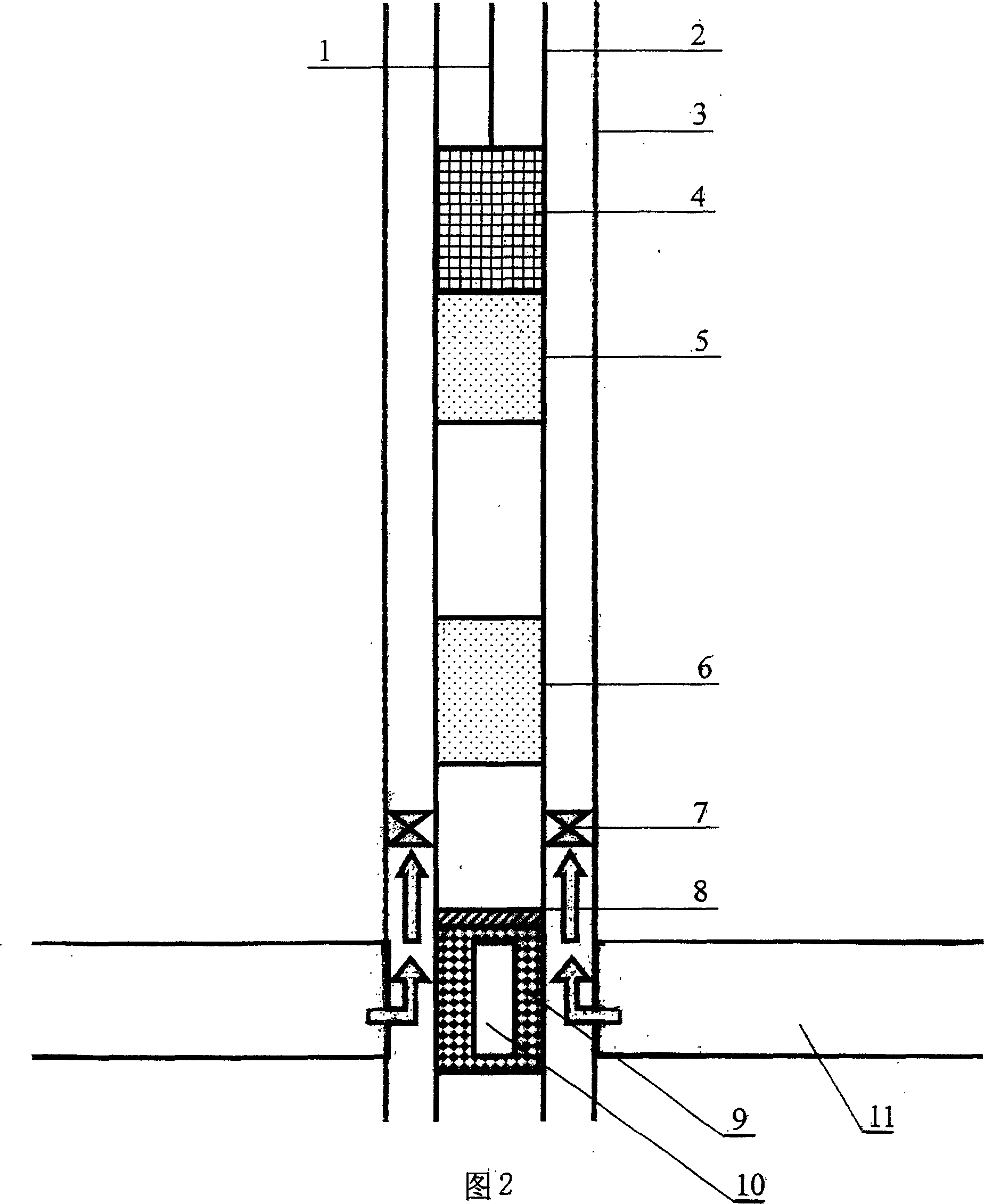

Well closing pressure measuring method for low pressure low permeation oil field oil water well

ActiveCN1752408AExpand the detection rangeWellbore storage space shrinksSurveyOil productionEngineering

The invented method includes the following steps: firstly, taking out production pipe string; then down-placing piezometric pipe string with anti-vibration barrel and pressure meter; third, under the condition of that the packer is not set starting pump and making oil production; fourth, stopping pump and setting packer; fifth, well shut-in, pressure meter can be used for automatically measuring and recording pressure build-up data; finally, taking out pressure meter and inputting the above-mentioned data into computer, then processing and analyzing said pressure data.

Owner:PETROCHINA CO LTD

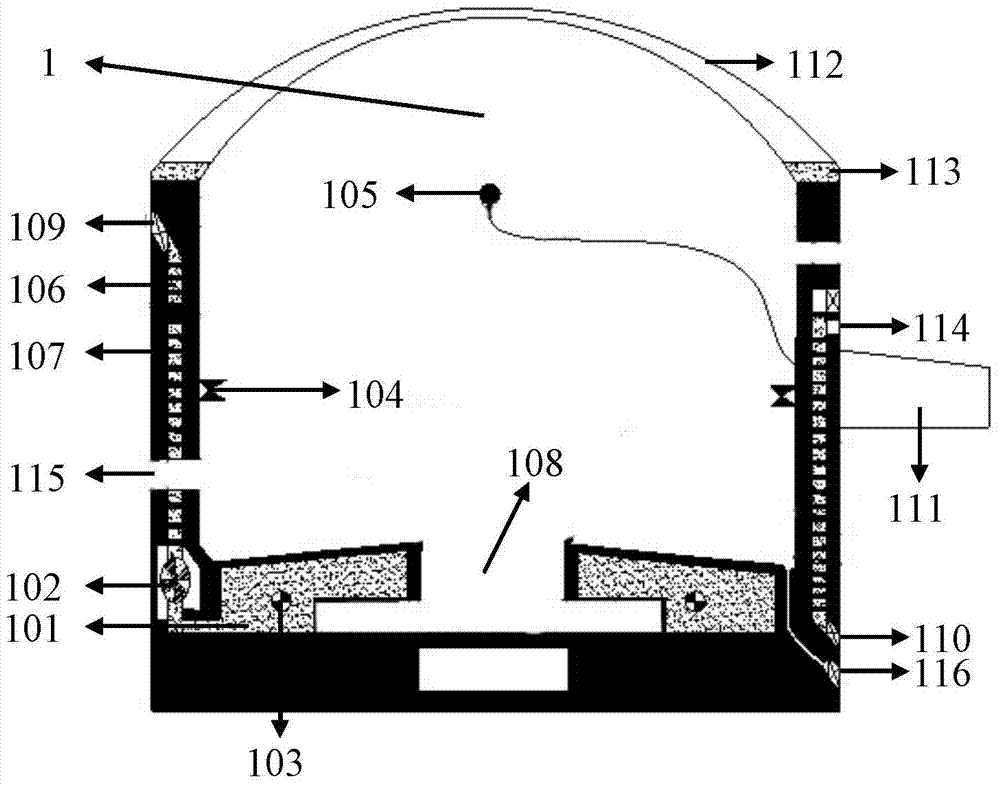

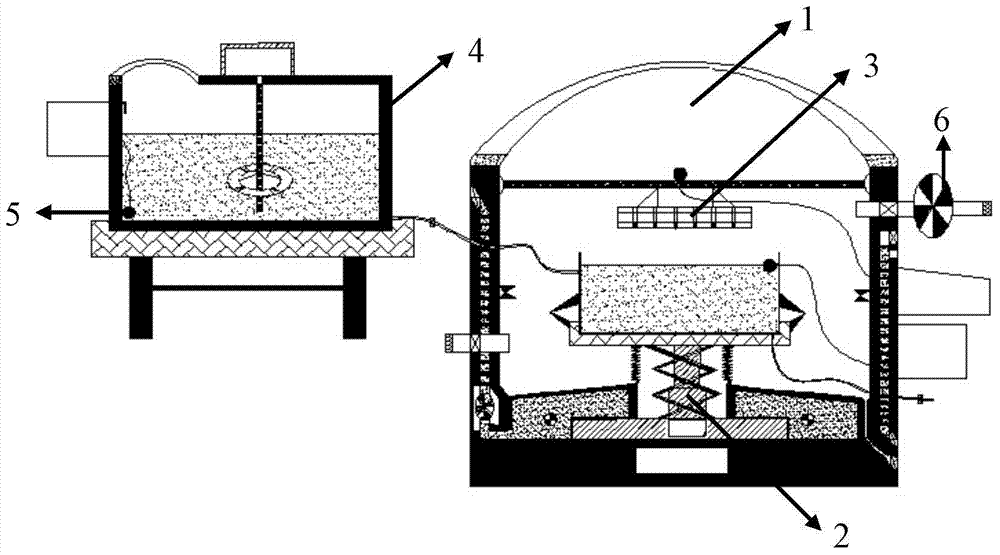

Constant temperature and constant humidity system and application thereof in alternate immersion test machine

ActiveCN104713821ASmall fluctuationSuitable temperature and humidityWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceWater channelEngineering

The invention provides a constant temperature and constant humidity system and an alternate immersion test machine comprising the constant temperature and constant humidity system. The constant temperature and constant humidity system comprises a reservoir, a water pump, heater(s), humidifier(s), a temperature and humidity sensor and a circulating water channel, wherein the circulating water channel is arranged on / in the side wall of the system; the water in the reservoir is driven to enter the circulating water channel for circulating by the water pump; the one or more heater(s) is / are available, and is / are arranged in the reservoir and / or the circulating water channel; the one or more humidifier(s) is / are available, and is / are arranged in a space formed in the constant temperature and constant humidity system. After the constant temperature and constant humidity system is adopted, the temperature and the humidity in a target operating space can be accurately controlled, so that the constant temperature and constant humidity system is especially suitable for the alternate immersion test machine for a stress corrosion resistance test.

Owner:AEROSPACE PRECISION PROD INC LTD

Automatic detection method of abundance of methane-oxidizing bacteria

ActiveCN105018609AFully automatedReduce mistakesMicrobiological testing/measurementMicrobial oilWorkstation

The invention discloses an automatic detection method of abundance of methane-oxidizing bacteria. The automatic detection method comprises the following steps: building an automation workstation of an original state microbial oil gas and hydrate exploration technology, treating samples, finishing pipetting by the adoption of an automatic liquid treatment device at the workstation, extracting and purifying DNA by automatic nucleic acid extraction equipment, carrying out agarose electrophoresis detection, carrying out real-time fluorogenic quantitative PCR detection on abundance of methane-oxidizing bacteria, obtaining the abundance result and the like. Based on an automatic analysis method, nucleic acid extraction and purification of methane-oxidizing bacteria are automated; preparation of a specific gene PCR reaction system is automated, errors caused by human factors introduced by manual operation are minimized, operation steps are carried out in a clean environment, the whole detection process is controlled through computer software, detection procedures can be traced, and system errors can be corrected uniformly.

Owner:GUANGZHOU ENENTA CHEM SCI & TECH

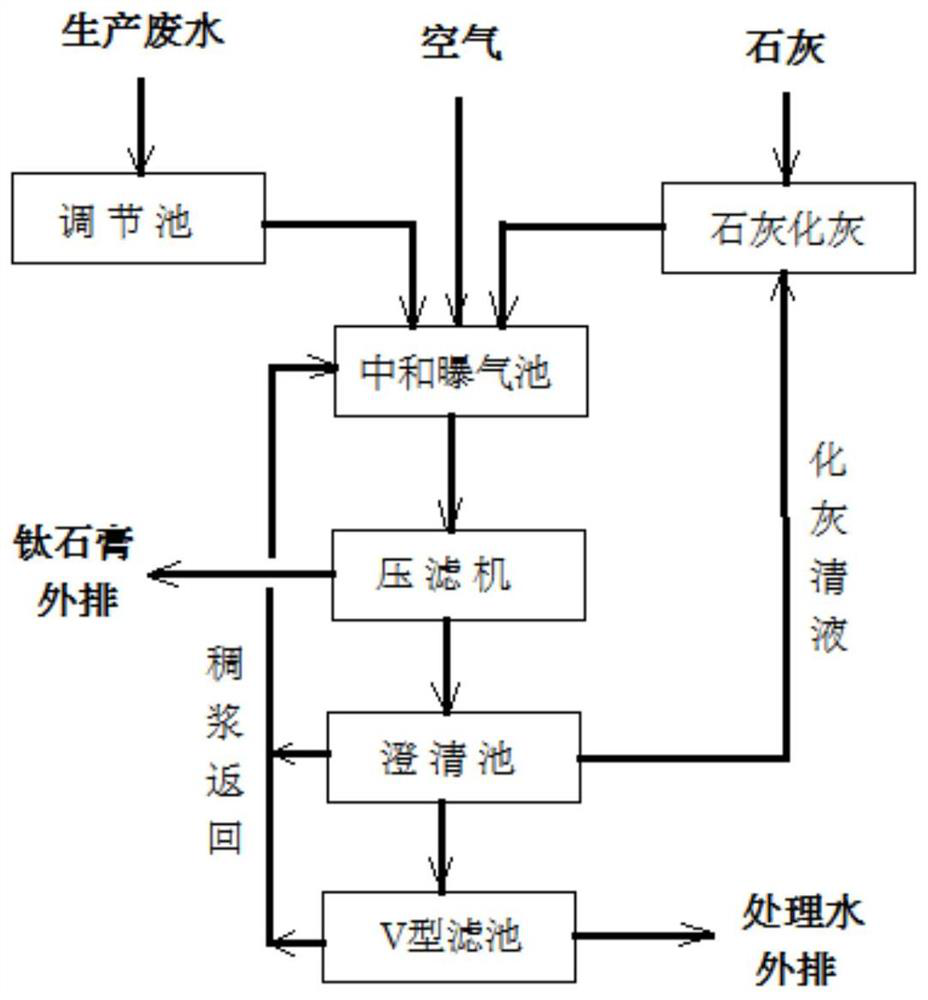

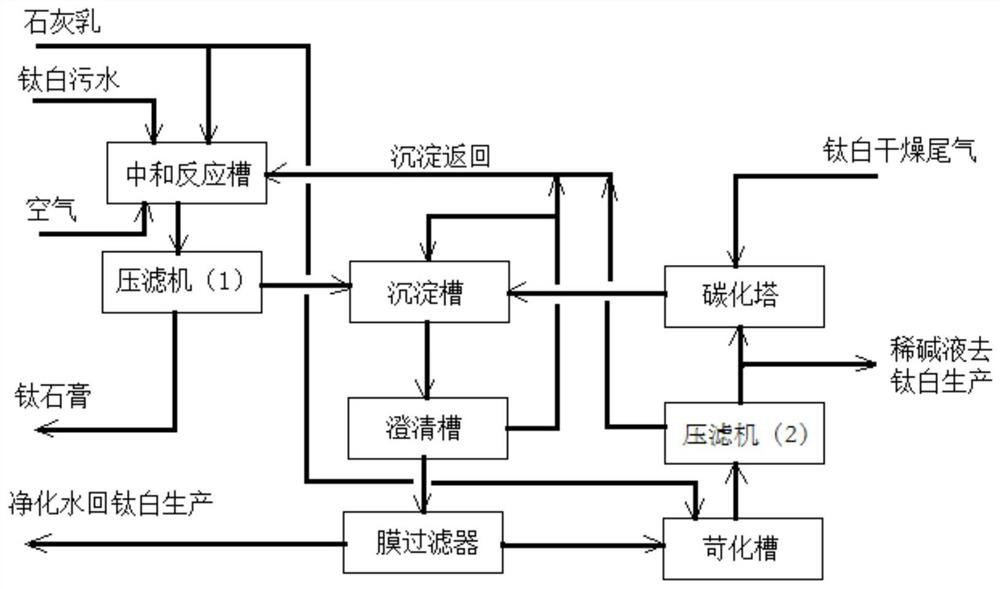

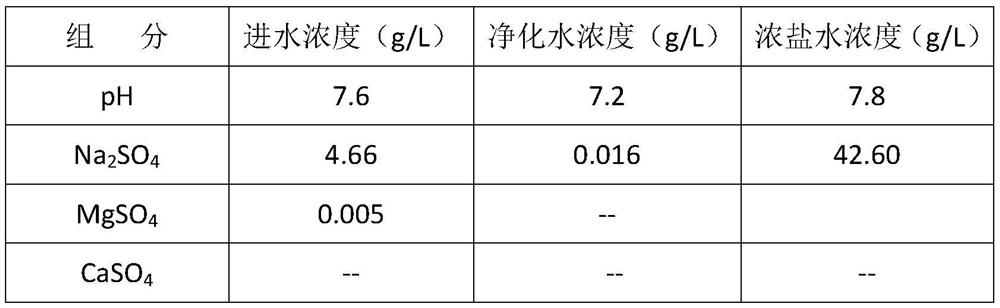

Production method for full-resource cyclic utilization of sulfuric-acid-method titanium dioxide production wastewater

PendingCN112499813ASave a lot of needReusing a large amount of emission reductionTreatment involving filtrationMultistage water/sewage treatmentChemistryRaw water

The invention discloses a production method for full-resource cyclic utilization of sulfuric-acid-method titanium dioxide production wastewater, which comprises the following steps of: neutralizing wastewater produced by sulfuric acid method titanium dioxide production by lime, separating gypsum by a filter press to obtain treated wastewater, and adding a recycled sodium carbonate solution to precipitate saturated calcium sulfate in the treated wastewater; clarifying the slurry to separate calcium carbonate precipitate and a sodium sulfate solution, and carrying out membrane separation on theseparated dilute sodium sulfate solution through a membrane filter; adding lime into a concentrated-phase sodium sulfate solution obtained after membrane separation for causticization reaction, takinga filtrate as a sodium hydroxide solution, employing carbon dioxide-containing tail gas generated in the titanium dioxide production process for carbonization, obtaining a sodium carbonate solution,and then returning the treated wastewater to precipitate saturated calcium sulfate. The method economically solves the technical problem that the lime neutralization treatment wastewater cannot be economically recycled in the sulfuric acid method titanium dioxide production process, eliminates the influence factors of outward discharge of the existing neutralization treatment wastewater on the environmental water body, and saves a large amount of raw water resources for production.

Owner:CHENGDU QIANLIJIN TECHCAL INNOVATION CO LTD

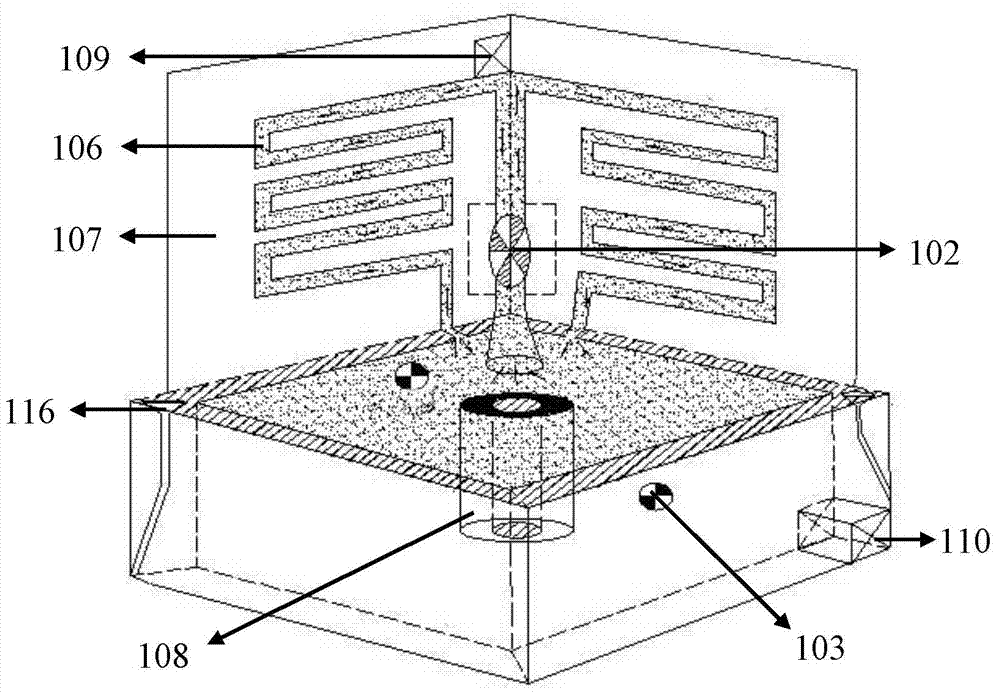

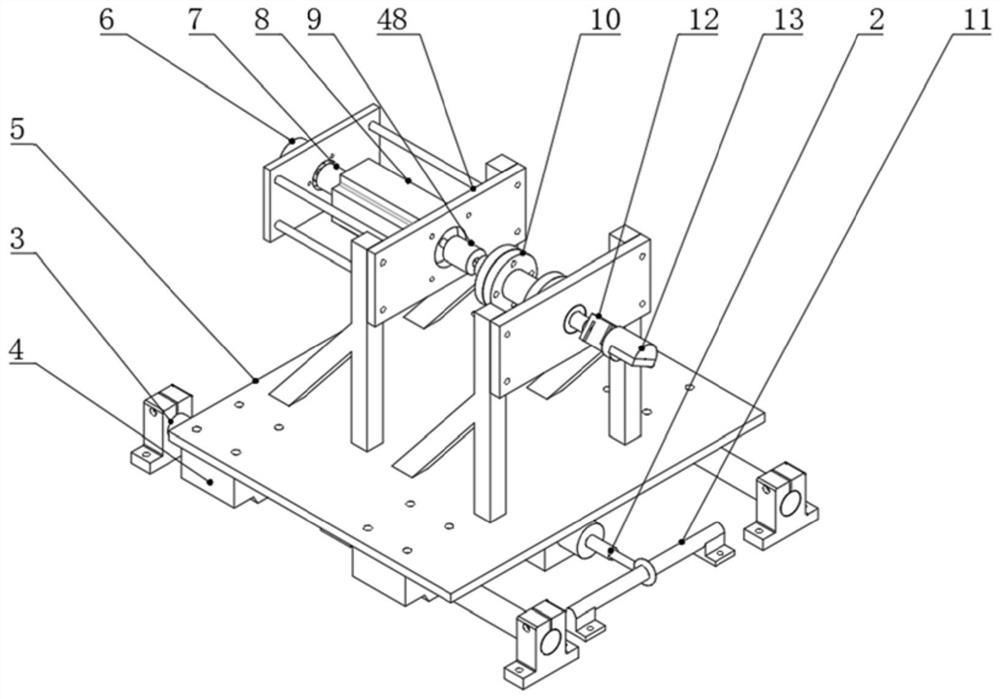

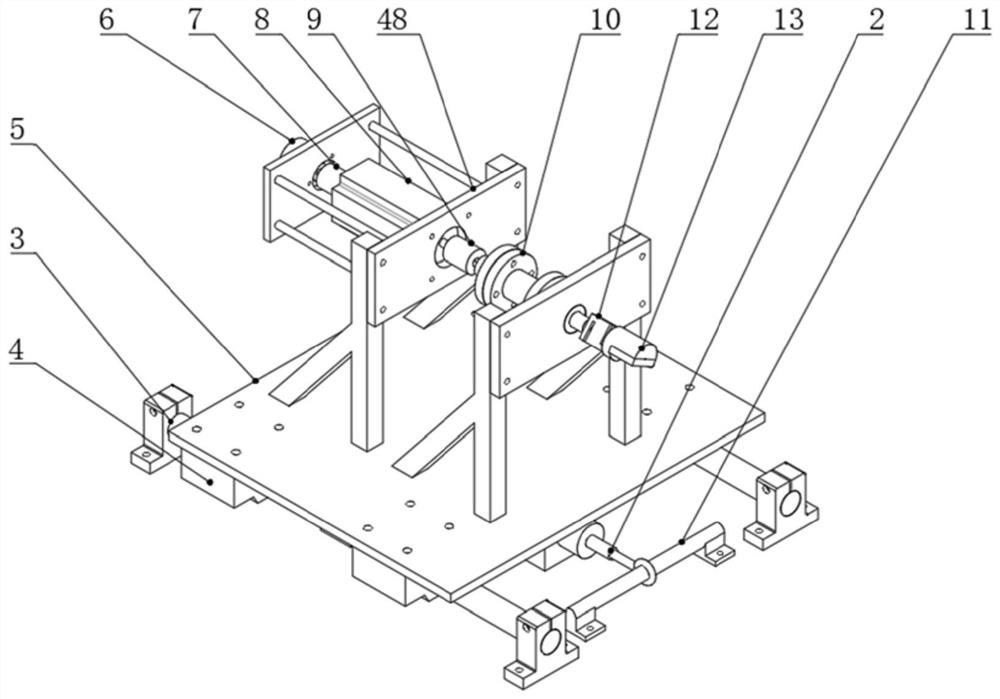

Pneumatic control-based lifting steel wire rope internal multi-wire spiral contact testing device and method

ActiveCN111678778AStudy friction behaviorHigh precisionMaterial strength using tensile/compressive forcesInvestigating abrasion/wear resistanceManufacturing engineeringWire rope

The invention discloses a pneumatic control-based lifting steel wire rope internal multi-wire spiral contact testing device and a testing method thereof. The device comprises a workbench, a steel wirerope strand internal multi-wire spiral contact mechanism based on pneumatic control, a steel wire rope strand internal multi-wire loading mechanism based on pneumatic control and a roller loading mechanism. According to the pneumatic control-based lifting steel wire rope internal multi-wire spiral contact testing device, the working condition of multi-wire spiral contact in the steel wire rope strand can be realized on one experimental device, and two motion behaviors of frictional wear between steel wires in the steel wire rope strand and frictional wear between steel layers can be truly simulated. The experiment device is pneumatically controlled, so that the loading force of each part is adjustable and controllable, the control process is simpler and more convenient, and the experimentdata is more accurate.

Owner:CHINA UNIV OF MINING & TECH +1

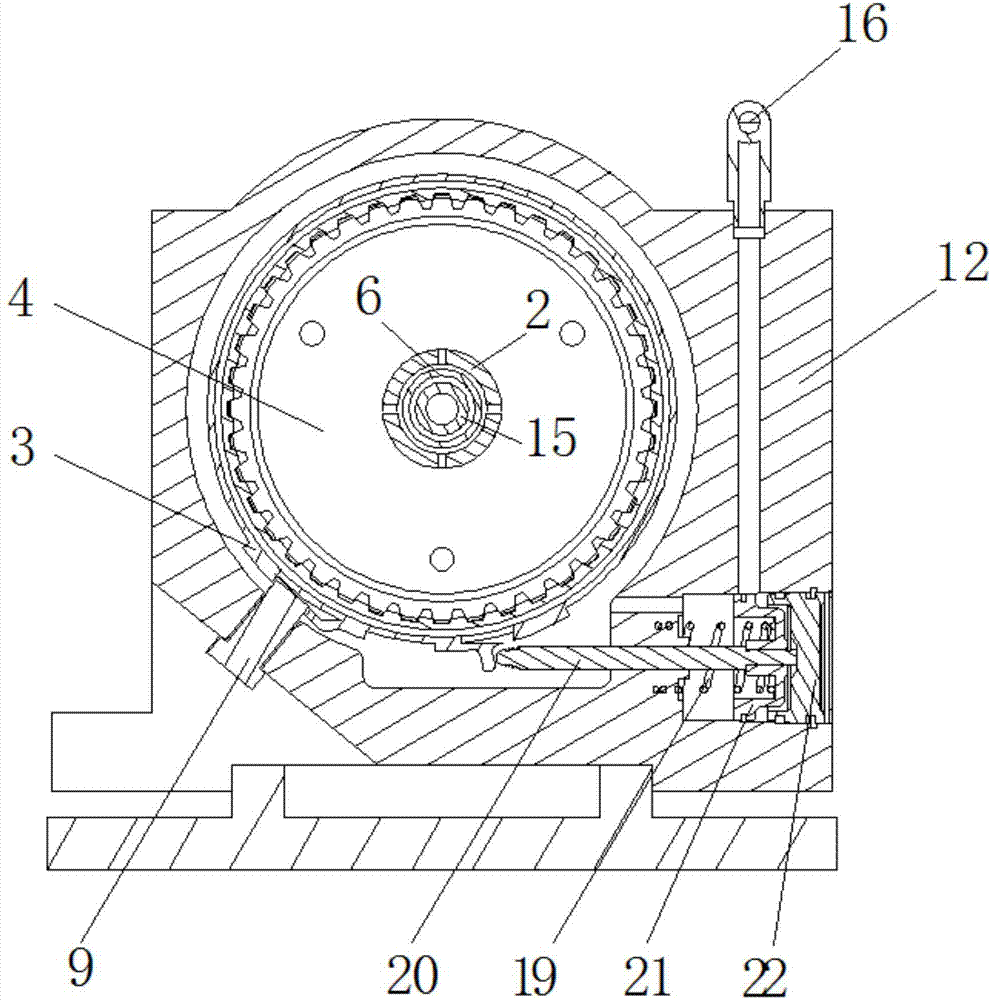

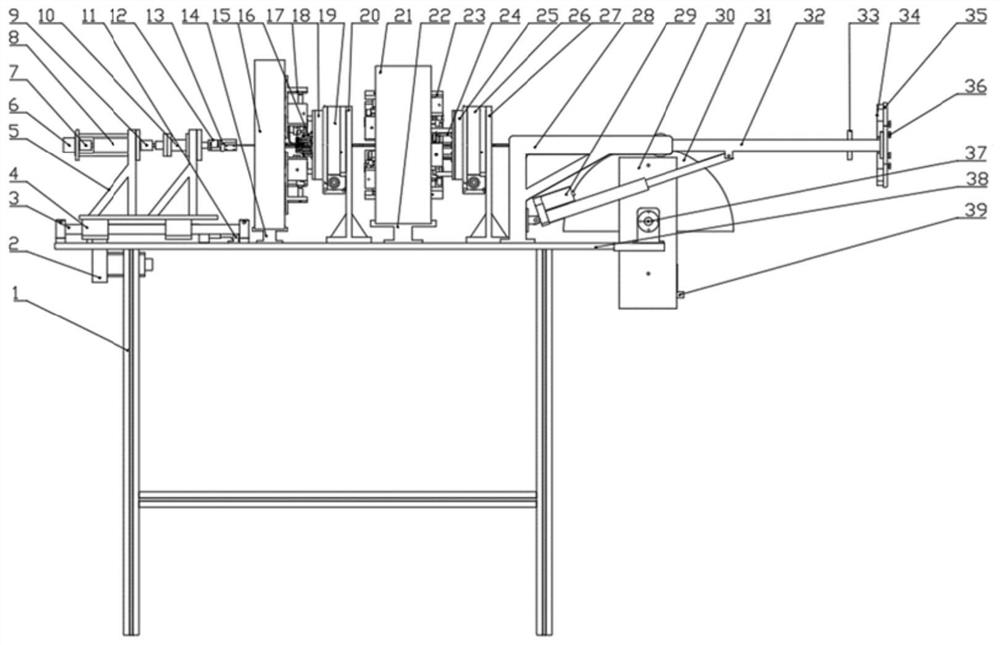

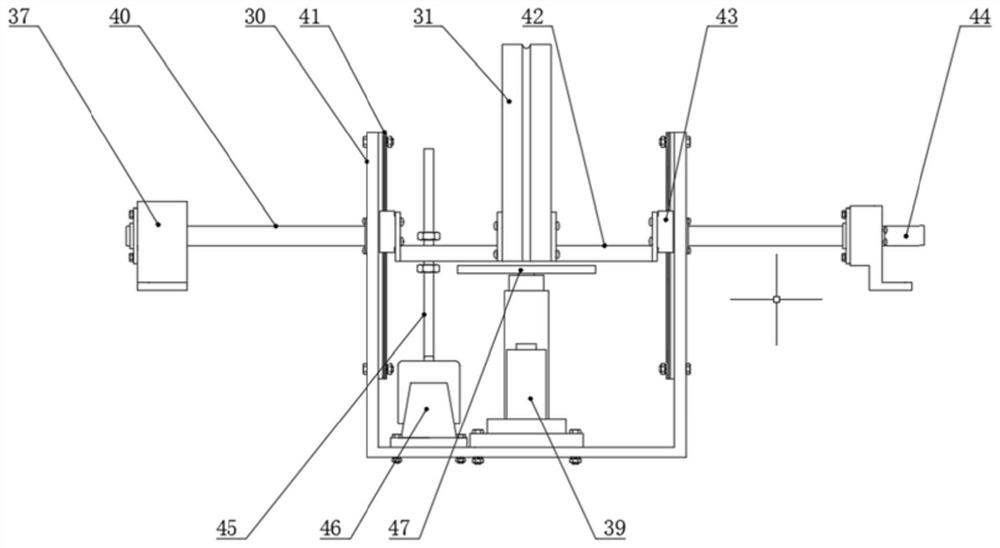

Automatic gearbox brake belt experiment device

ActiveCN107884184AEliminate influencing factorsSolve the problem of the impact of performance experiment dataMachine gearing/transmission testingAutomatic transmissionInterference factor

The invention relates to the brake belt technology field and particularly relates to an automatic gearbox brake belt experiment device. A brake belt is sleeved on the outer side of a clutch, a right end of the clutch is connected with a rotation disc, the rotation disc is connected with a positioning disc, a right end of the positioning disc is connected with a rotating shaft of the stand, a fixedsleeve is arranged in a cylindrical shaft of the rotation disc, a left end of a base is provided with a torque sensor, an adapter disc is connected with an oil supply pipeline on the stand, a pistontop rod is in contact with a stopper at one end of the brake belt, an end portion of the piston top rod is provided with a piston body, a return spring is arranged between the piston body and an innerwall of the base, and a brake pressure supply oil path is connected between a piston cover inside a piston cavity and the piston body through a tee pipe. Clutch hub, clutch, brake pressure supply oiland lubricating oil work conditions can be simulated, interference factors caused by parts in an integral machine experiment are eliminated, and an influence problem caused by the interference factors of other parts during brake belt experiments can be solved.

Owner:HARBIN DONGAN AUTOMOTIVE ENGINE MFG CO LTD

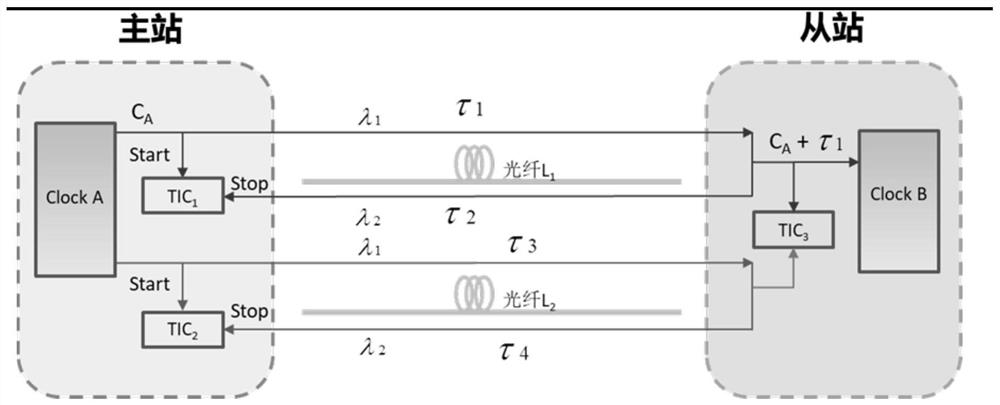

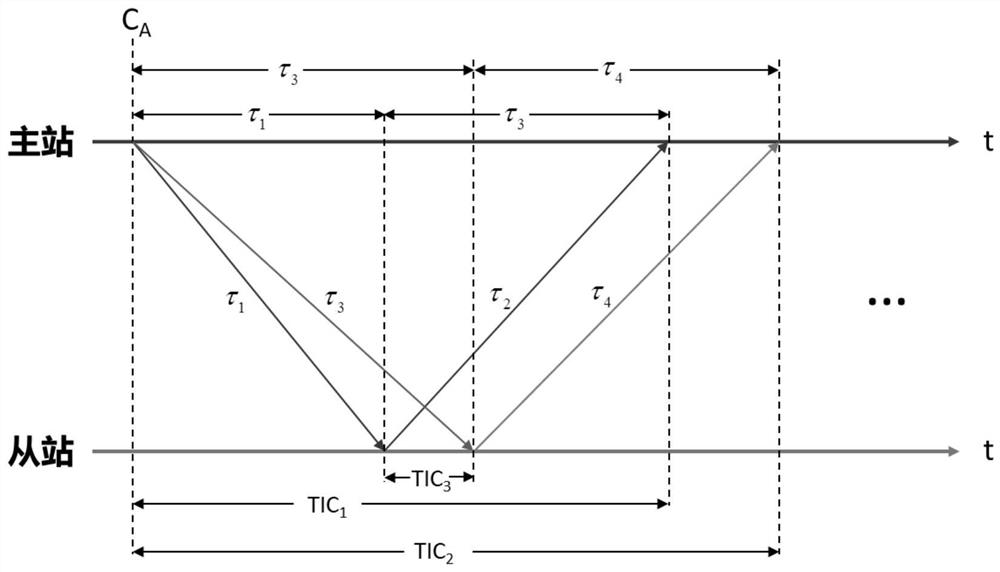

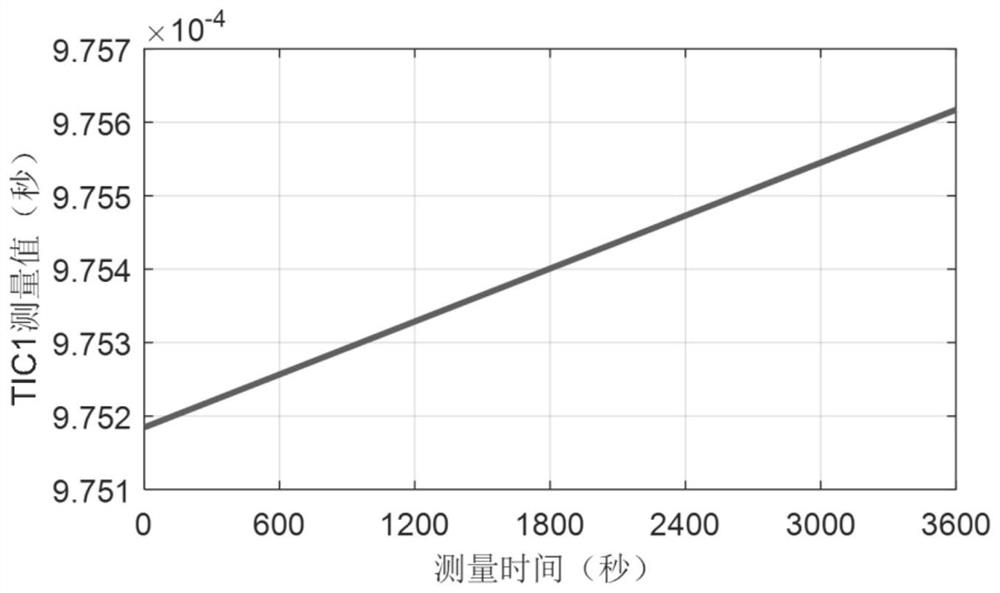

Double-fiber double-loop-back time delay deviation estimation compensation method in optical fiber time transmission

ActiveCN112202524AEliminate influencing factorsIncrease engineering costTime-division multiplexTime delaysMaster station

The invention discloses a double-fiber double-loop-back time delay deviation estimation compensation method in optical fiber time transmission. The method comprises the following steps: acquiring measured values TIC1, TIC2 and TIC3 through three time measurement modules; calculating a one-way time delay value tau 1 from the master station to the slave station according to the obtained time delay value and time delay ratio relation; the obtained time delay value tau 1 compensates a slave station clock in a slave station time delay compensation module to realize master-slave station time synchronization; and repeating the above steps to obtain the real-time value of tau 1, thereby realizing real-time time synchronization of the master station and the slave station. According to the method, the influence of environment temperature change on the optical fiber time synchronization precision can be eliminated, the influence that the optical fiber length of an existing network cannot be measured and the optical fiber length is affected by temperature change can be eliminated, the time delay deviation of a time signal during transmission in an optical fiber link can be accurately measured,real-time automatic compensation can be realized, and the optical fiber time transmission precision can be improved.

Owner:NAVAL UNIV OF ENG PLA

Construction method of bridge prestress continuous box girder

InactiveCN111041966AQuality assuranceSimple construction processBridge erection/assemblyBridge materialsPre stressArchitectural engineering

The invention provides a construction method of a bridge prestress continuous box girder. The construction method comprises the steps that a foundation is treated; erecting and pre-pressing of a bracket is carried out; a template is manufactured and installed; reinforcing steel bars, corrugated pipes and steel strands are installed; concrete construction is carried out, and box girder tensioning is carried out. The construction process provided by the invention is effectively simplified, original numerous influence factors are eliminated, the advantages of few reinforcing bars and light structure are achieved, the overall quality of subsequent bridges is guaranteed, a good market prospect is achieved, and the construction method is suitable for popularization and application.

Owner:江苏永联精筑建设集团有限公司

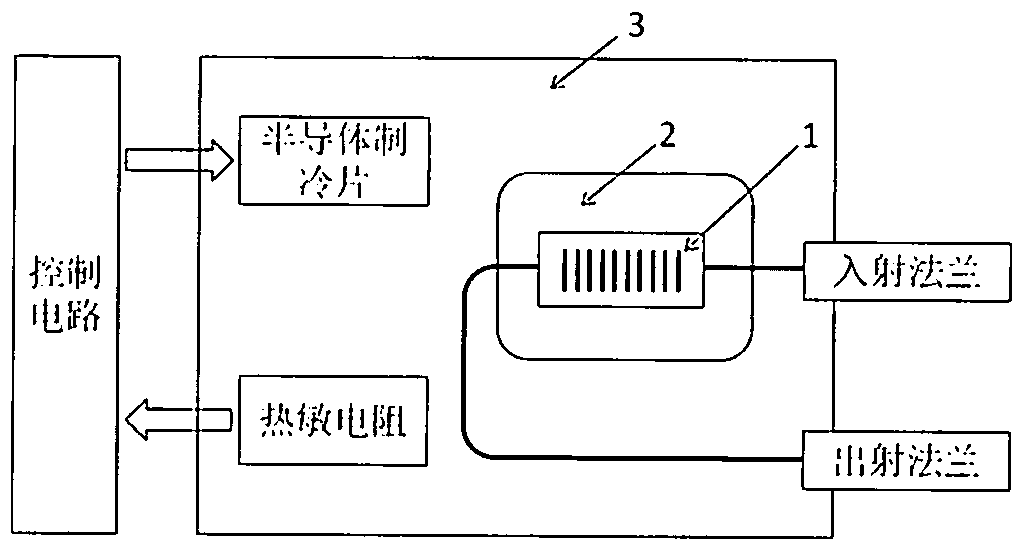

Constant-temperature constant-strain type fiber bragg grating standard device

PendingCN110940370AEliminate wavelength driftEliminate influencing factorsInstrumentsWavelengthMaterials science

The invention discloses a constant-temperature constant-strain type fiber bragg grating standard device, and belongs to the technical field of optical fiber sensing. The fiber bragg grating is placedin a constant-temperature constant-strain environment, influence factors of wavelength drift are eliminated, and the fiber bragg grating with the stable center wavelength is obtained. The fiber bragggrating sensing demodulator directly measures the central wavelength of the fiber bragg grating, and the precision of the demodulator can be detected and the demodulator can be calibrated by comparingthe measurement reading with the actual wavelength. The device is suitable for calibrating the demodulator adopting various demodulation methods, and has good compatibility.

Owner:NANKAI UNIV

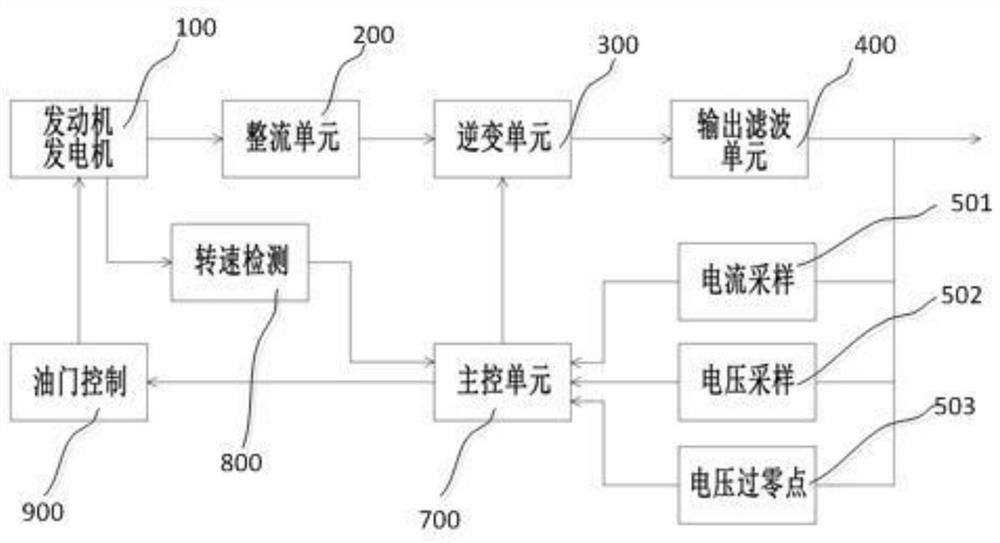

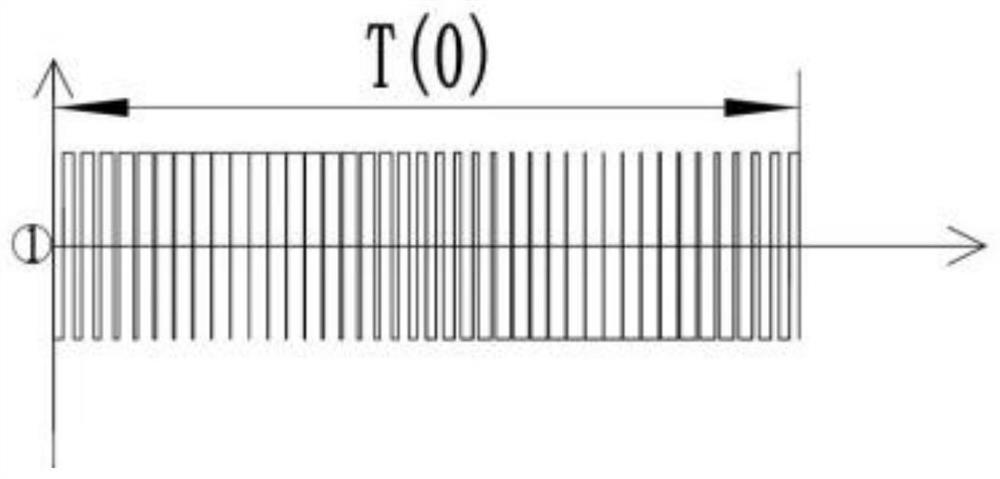

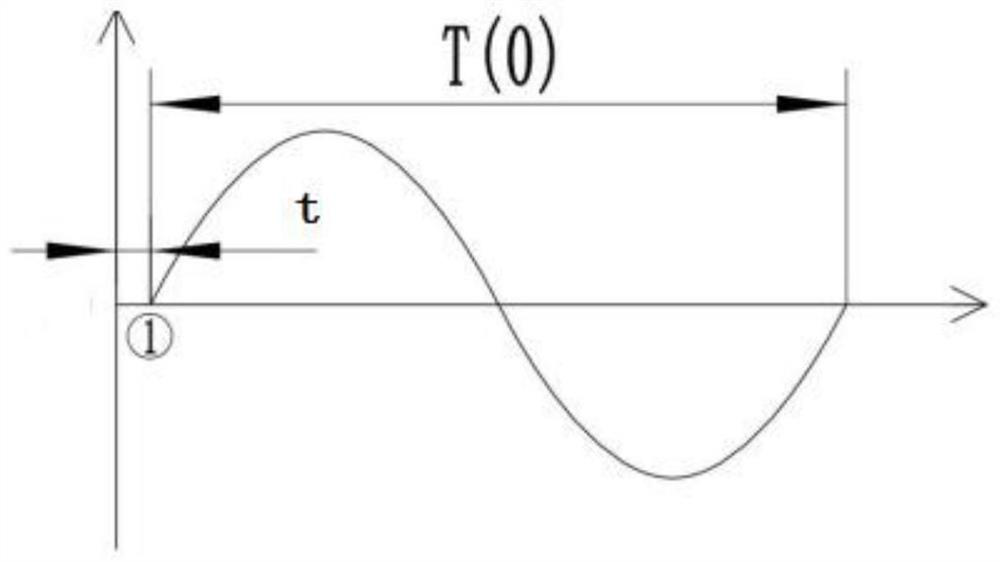

A Phase Synchronization Method for Parallel Operation of Multiple Generating Sets

ActiveCN110190634BPhase coincidenceSolve the problem of low reliability of parallel operationSingle network parallel feeding arrangementsThrottle controlVoltage amplitude

In order to solve the problem of low reliability of parallel operation of generator sets in the prior art, the present invention provides a phase synchronization method for parallel operation of multiple generator sets. The generator set includes an engine generator, a rectifier unit, an inverter unit and an output filter. It also includes a main control unit and a throttle control unit; it also includes a current sampling unit, a voltage sampling unit and a voltage zero-crossing unit, and the output ends of the output filtering unit are respectively connected with the current sampling unit, the voltage sampling unit and the voltage zero-crossing unit. In this application, the actual output current of the generator set, the value of the output voltage, and the time difference between the actual zero-crossing point of the output voltage and the software zero-crossing point are collected, and compared with the preset value in the main control unit of the generator set, the period of the output voltage is adjusted. The value and voltage amplitude, the phase of synchronous output voltage, the power distribution of different units in parallel, improve the reliability of parallel operation of generator sets, and improve the efficiency and economy of unit operation.

Owner:CHONGQING SENCI ELECTRIC MACHINERY +1

Compensation method of steel ball surface defect measurement system based on optical fiber sensing

InactiveCN103776843BEliminate influencing factorsQuick judgmentMaterial analysis by optical meansOptical power meterSteel ball

The invention particularly discloses a compensation method of a steel ball surface detect measuring system based on optical fiber sensing. The compensation method of the steel ball surface detect measuring system based on optical fiber sensing comprises the following steps: step 1, for a sensor structure that a single optical fiber transmits scattered light and a plurality of groups of optical fibers receive scattered light, measuring by an optical power meter so as to obtain detection incidence power P0 and corresponding light power P1, P2,..., and Pn received by multiple groups of optical fibers; step 2, collecting data of the light power P1, P2,..., and Pn which are obtained in the step 1 by a multi-path high-speed synchronous data collecting plate, thereby obtaining digital signals with N light intensity; summing the N groups of light intensity so as to obtain P=P1+P2+P3+...+Pn; step 3, carrying out division operation on the P, P1, P2, ..., and PN which are obtained from the step 2, that is, dividing multiple groups of received light intensity by each group of received light intensity so as to obtain specific values P / P1, P / P2, ..., and P / P(n-1), thereby obtaining the light intensity specific values when the sensor and a measured surface are oblique at different angles; step 4, establishing a function of a clearance varying along with the specific value; step 5, determining the coefficients a0, a1, a2, ..., and a(n-1); and step 6, substituting the coefficient values from the step 5 into the formula (1), thereby obtaining the accurate gap value.

Owner:UNIV OF JINAN

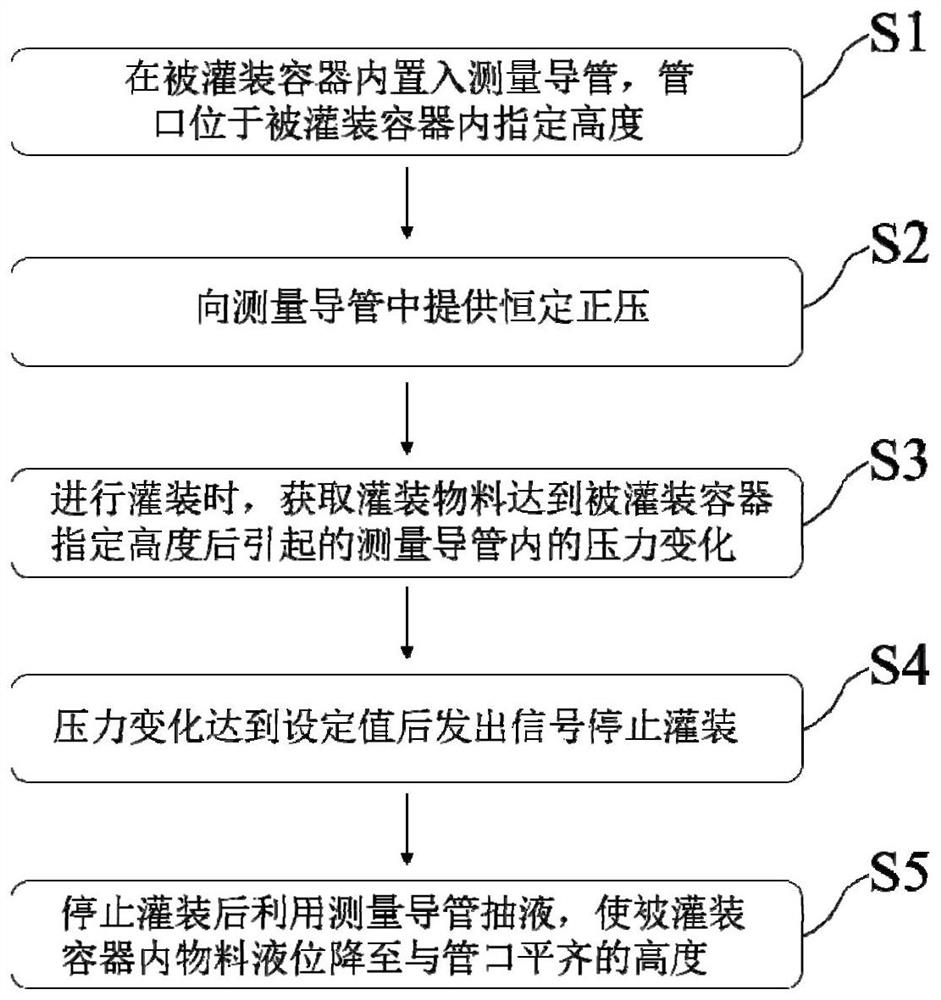

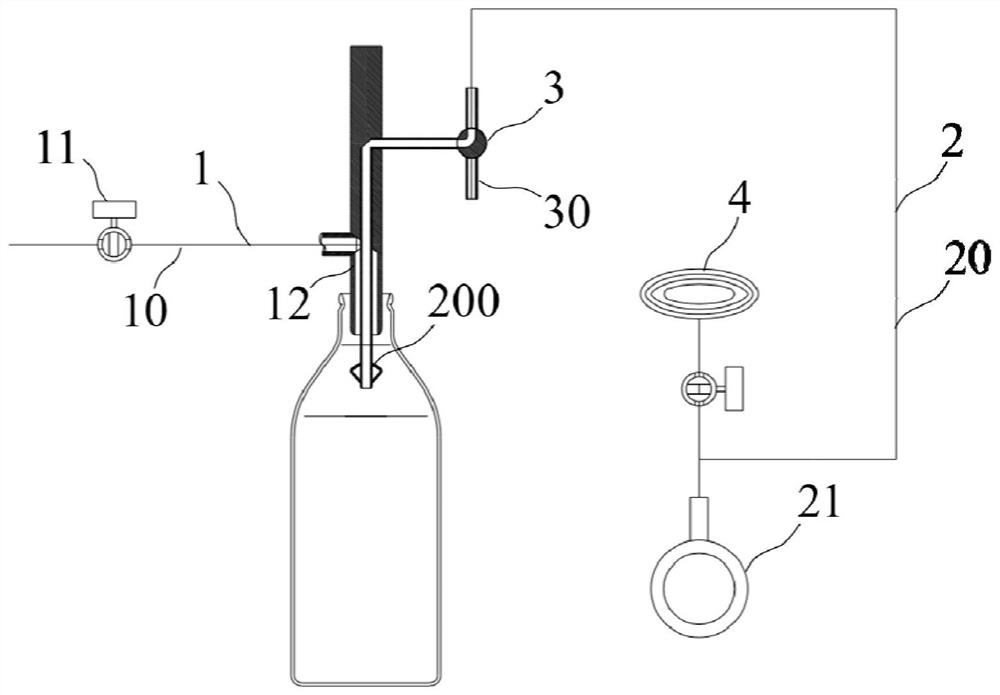

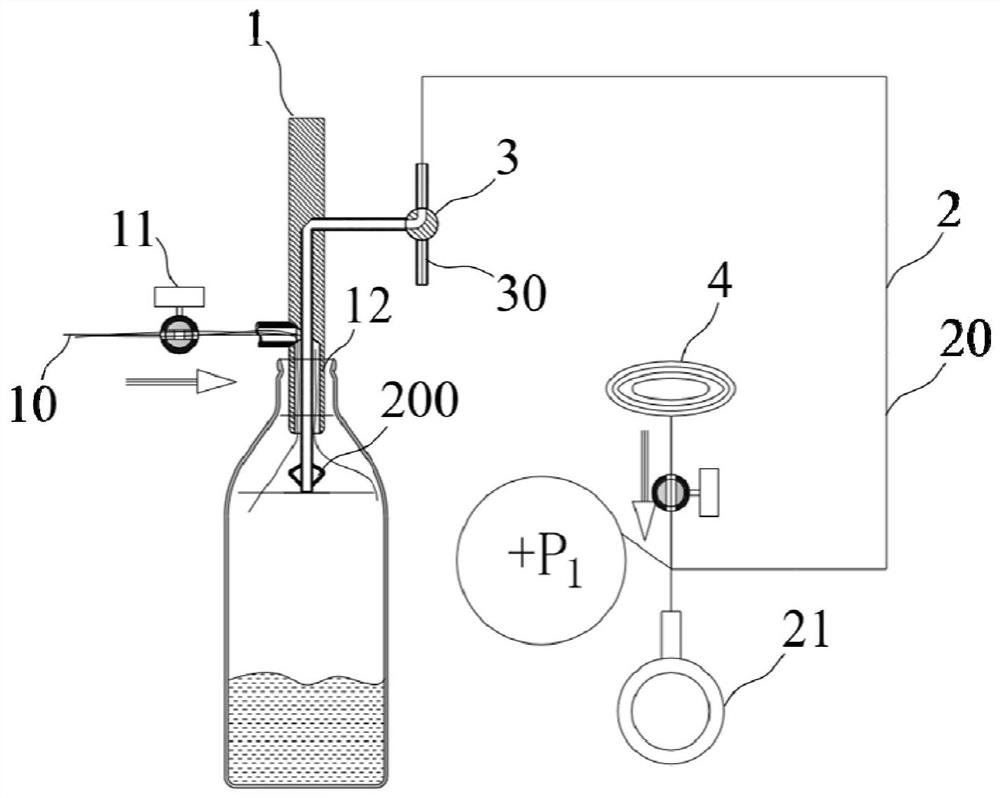

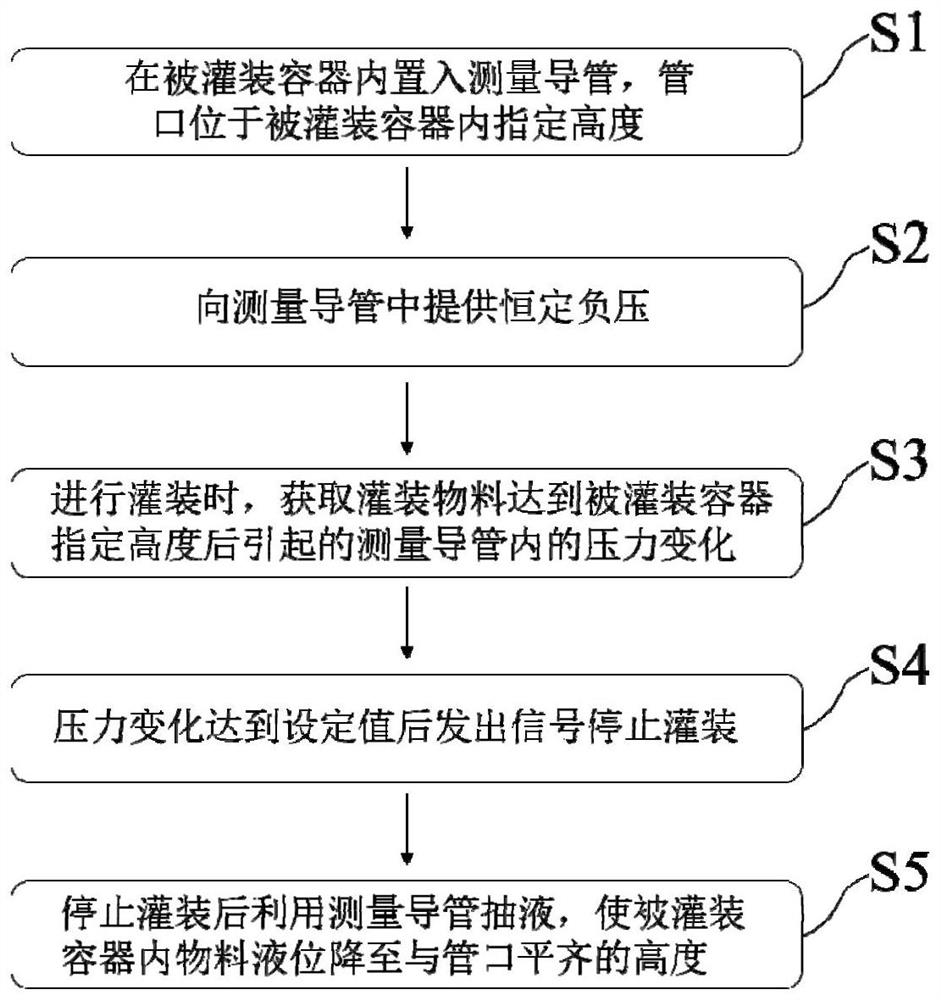

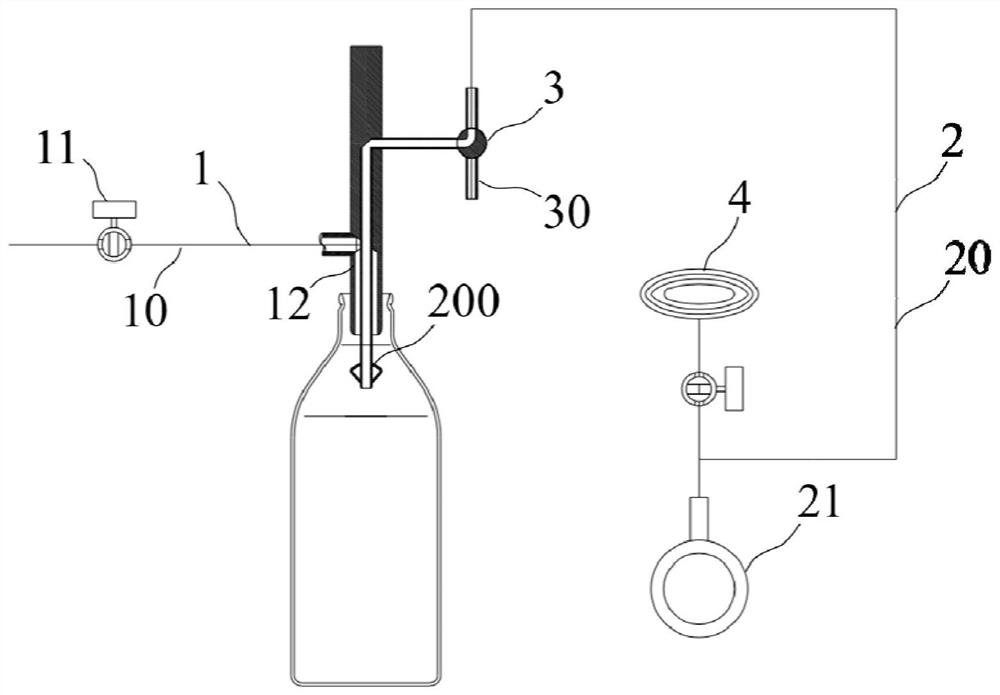

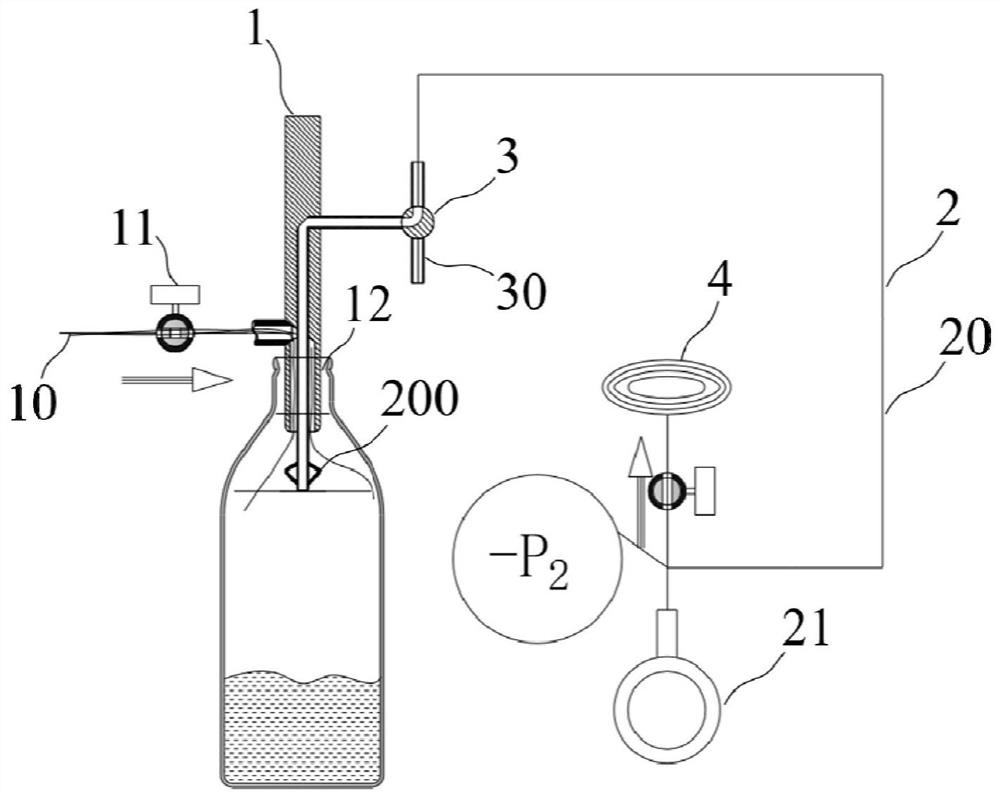

A positive pressure non-contact liquid filling method for controlling liquid level

ActiveCN111003229BFast trigger pressure change setpoint speedHigh speedPackaging automatic controlLiquid materialLiquid stateEngineering

The invention discloses a method for controlling liquid level of non-contact liquid filling by positive pressure method, which belongs to the technical field of filling. It includes the following steps: S1, inserting a measuring conduit into the container to be filled, and the nozzle is located at a specified height in the container to be filled; S2, providing a constant positive pressure to the measuring conduit; S3, obtaining the filling liquid state during filling The pressure change in the measuring conduit caused by the material reaching the specified height of the filled container; S4. After the pressure change reaches the set value, a signal is sent to stop filling; S5. After stopping the filling, use the measuring conduit to pump liquid to make the filled container The liquid level of the internal liquid material drops to the level of the nozzle. The invention introduces a constant positive pressure into the measuring conduit, and when the liquid level reaches the height of the nozzle surface of the measuring conduit during filling, it can cause obvious pressure changes in the measuring conduit, thereby accelerating the process of the pressure change reaching the set value, and quickly Timely control of filling stop, small filling error, accurate liquid level control and increased filling efficiency.

Owner:安徽沛愉包装科技有限公司

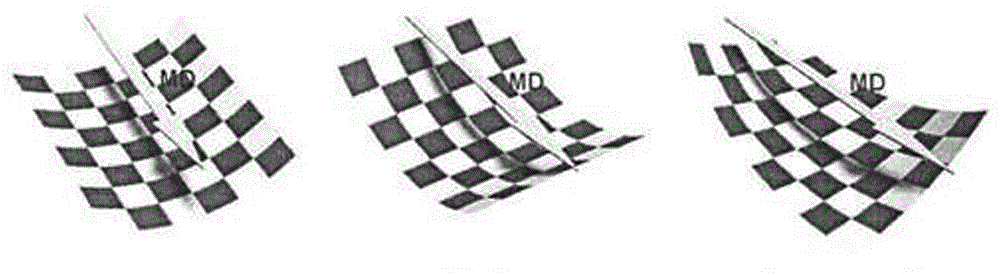

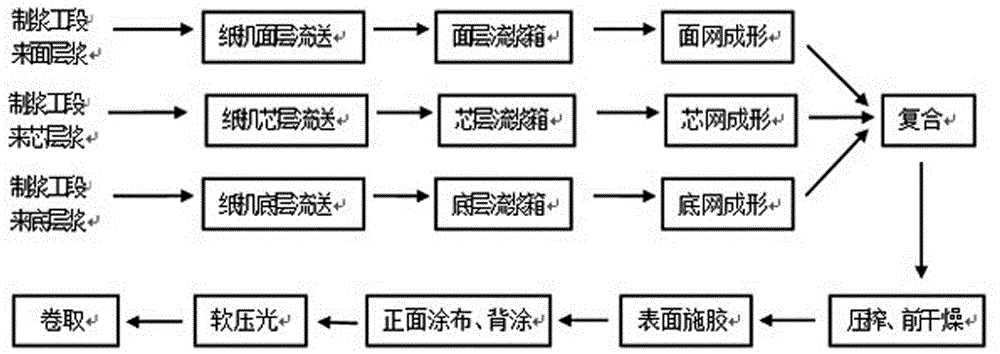

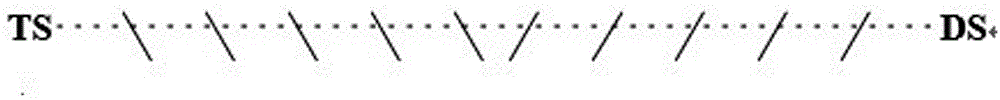

Warping adjustment method adopted in cardboard coating

ActiveCN104611974ASolution and adjustment methodEliminates major contributors to warpagePaper coatingMachine wet endFiberCardboard

The invention discloses a warping adjustment method adopted in cardboard coating. The warping adjustment method adopted in cardboard coating specifically comprises the steps of 1 determining fiber arrangement direction; 2 adjusting a pulp fluid box according the fiber arrangement direction, wherein a balance pipe of the pulp fluid box is adjusted if the fiber arrangement direction deviates to the same direction, and a lip plate deviation-preventing system of the pulp fluid box is adjusted if the fiber arrangement direction is splayed; 3 adding 10%-30% by starch weight of PVA assistant into a back-coating starch for cardboard coating. According to the warping adjustment method adopted in cardboard coating, main factors influencing paper warping are thoroughly eliminated by groping and summarizing production practice after primary causes of forward warping and opposite-angle warping in the cardboard coating production process are analyzed, a most direct and effective method for adjusting forward warping and opposite-angle warping in the cardboard coating production process is obtained, the warping adjustment method can be directly used for improving pass rate of products and has good economic benefit.

Owner:ZHUHAI S E Z HONGTA RENHENG PAPER

A kind of planting method of lotus root

ActiveCN107787794BIncrease productionQuality improvementCalcareous fertilisersAnimal corpse fertilisersGreen manureHorticulture

The invention discloses a method of planting lotus root. The method of planting the lotus root comprises the following steps of (1) selection of a lotus root field; (2) construction of a lotus root pond; (3) selection and processing of lotus seeds; (4) planting; (5) field managing: A, germination period; B, vigorous growth period; C, lotus root growth period; (6) water management; and (7) harvesting. The method of planting the lotus root is simple and easy to implement and can significantly increase the yield of the lotus root; the lotus root obtained by using the method is crisp and tender and has lots of moisture and good taste; by using a lotus root cultivation substrate, the application of chemical fertilizers is significantly reduced, the quality of the lotus root is effectively improved, the cost is reduced, and at the same time, the harm to the environment is reduced. According to the lotus root cultivation substrate, through the reasonable addition of bone powder and eggshell powder, phosphorus can be effectively supplemented in original soil; through the addition of green manure, nitrogen fertilizer and potash fertilizer are supplemented; the addition of vermiculite in thelotus root cultivation substrate can increase the permeability of the substrate, is conducive to the growth of the lotus root, and at the same time facilitates the digging out of the lotus root in the later period.

Owner:云南丰圣生物科技有限公司

Pneumatic control-based multi-filament spiral contact test device and method inside hoisting wire rope

ActiveCN111678778BStudy friction behaviorHigh precisionMaterial strength using tensile/compressive forcesInvestigating abrasion/wear resistanceContact testWire rope

The invention discloses a pneumatic control-based multi-filament spiral contact testing device inside a hoisting wire rope and a testing method thereof. Controlled wire rope internal multi-wire loading mechanism and drum loading mechanism. The multi-wire spiral contact test device inside the hoisting steel wire rope based on pneumatic control in the present invention can realize the working condition of the multi-wire spiral contact inside the steel wire rope strand on one experimental device, and truly simulate the friction and wear between the steel wires inside the steel wire rope strand and the steel layer There are two kinds of motion behaviors of friction and wear between the steel layer. The experimental device adopts pneumatic control to realize the adjustable and controllable loading force of each part, which makes the control process easier and the experimental data more accurate.

Owner:CHINA UNIV OF MINING & TECH +1

Well closing pressure measuring method for low pressure low permeation oil field oil water well

The invented method includes the following steps: firstly, taking out production pipe string; then down-placing piezometric pipe string with anti-vibration barrel and pressure meter; third, under the condition of that the packer is not set starting pump and making oil production; fourth, stopping pump and setting packer; fifth, well shut-in, pressure meter can be used for automatically measuring and recording pressure build-up data; finally, taking out pressure meter and inputting the above-mentioned data into computer, then processing and analyzing said pressure data.

Owner:PETROCHINA CO LTD

A method for controlling liquid level of non-contact liquid filling by negative pressure method

ActiveCN111003230BHigh speedImprove effective filling efficiencyPackaging automatic controlLiquid materialMedicineLiquid state

The invention discloses a negative pressure non-contact liquid filling method for controlling liquid level, which belongs to the technical field of filling. It includes the following steps: S1, inserting a measuring conduit in the container to be filled, and the nozzle is located at a specified height in the container to be filled; S2, providing a constant negative pressure to the measuring conduit; S3, obtaining the filling liquid state during filling The pressure change in the measuring conduit caused by the material reaching the specified height of the filled container; S4. After the pressure change reaches the set value, a signal is sent to stop filling; S5. After stopping the filling, use the measuring conduit to pump liquid to make the filled container The liquid level of the internal liquid material drops to the level of the nozzle. The invention introduces a constant negative pressure into the measuring conduit, and when the liquid level reaches the height of the nozzle surface of the measuring conduit during filling, it can cause obvious pressure changes in the measuring conduit, thereby accelerating the process of the pressure change reaching the set value, and quickly Timely control of filling stop, small filling error, accurate liquid level control and increased filling efficiency.

Owner:安徽沛愉包装科技有限公司

An automatic transmission brake band test device

ActiveCN107884184BEliminate influencing factorsSolve the problem of the impact of performance experiment dataMachine gearing/transmission testingAutomatic transmissionInterference factor

The invention relates to the technical field of brake bands, in particular to an automatic transmission brake band experimental device. The brake band is sleeved on the outside of the clutch, the right end of the clutch is connected to the turntable, the turntable is connected to the positioning disk, the right end of the positioning disk is connected to the rotating shaft on the stand, a fixed sleeve is arranged in the cylindrical shaft of the turntable, and a The torque sensor, the adapter plate is connected with the oil supply pipeline on the stand, the piston push rod is in contact with the stopper at one end of the brake band, the end of the piston push rod is provided with a piston body, and the piston body and the inner wall of the base are provided There is a return spring, and the brake pressure supply oil circuit is connected between the piston cover and the piston body inside the piston cavity through a three-way pipe. This structure can simulate the working conditions of the clutch hub, clutch, brake pressure supply oil and lubricating oil, eliminate the interference factors caused by the parts in the whole machine experiment, and solve the influence of the interference factors of other components in the brake band experiment .

Owner:HARBIN DONGAN AUTOMOTIVE ENGINE MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com