Production method for full-resource cyclic utilization of sulfuric-acid-method titanium dioxide production wastewater

A technology for producing wastewater and production methods, applied in chemical instruments and methods, titanium compounds, titanium dioxide, etc., can solve the problems of difficulty in recycling economical utilization, production wastewater cannot be recycled and reused, etc. Utilize the effect of maximizing and saving a lot of needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

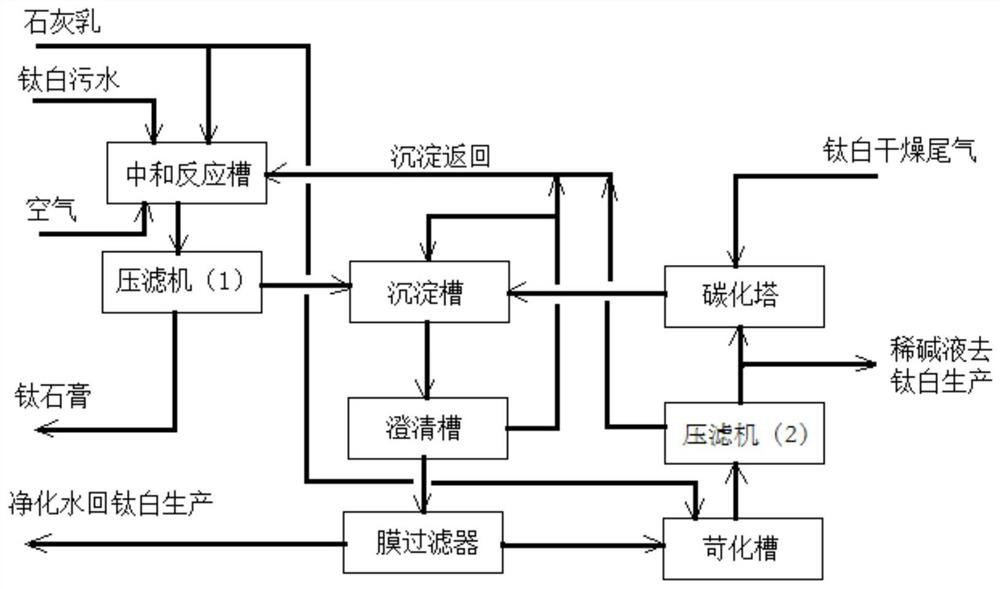

[0051] Such as figure 2 As shown, 1600L (specific gravity 1.05, containing 36.96g / L of sulfuric acid, 16.80g / L of ferrous sulfate, 0.525g / L of titanium sulfate, see Table 1) and hourly content of acid wastewater from sulfuric acid titanium dioxide production 29.0L of 170g / L calcium oxide milk of lime is neutralized in three series connected 2000L tanks with air distribution pipes at the bottom, and the air is blown into it for aeration and oxidation, and the residence time of the reaction materials is controlled for 1 hour , the pH value of the slurry is 7.5, and the slurry overflows from the top of the third-stage neutralization reaction tank and enters the filter press pump tank, and then is continuously sent to the filter press for pressure filtration separation, and 27.4 kg of filter cake with a water content of 45% is obtained per hour And 1685L treatment waste water (its composition of specific gravity 1.005 is shown in Table 2).

[0052] Table 1 Composition of titaniu...

Embodiment 2

[0063] Such as figure 2 As shown, the acid waste water from sulfuric acid titanium dioxide production is 240m3 per hour, the main composition is shown in Table 4, and 36.5m3 of milk of lime containing 200g / L calcium oxide per hour is placed in four series-connected 180m3 neutralization reaction tanks with stirring The neutralization reaction is carried out, and the bottom of the two-stage neutralization reaction tank is equipped with an air distribution pipe, and air is blown in for aeration and oxidation, and the residence time of the reaction material is controlled for 1.5 hours. The pH of the slurry is 7.5, and the slurry is obtained from the fourth stage. After overflowing from the top of the reaction tank and entering the filter press pump tank, it is continuously sent to the filter press for pressure filtration separation, and 45.5 tons of filter cake with a water content of 45% and 253 tons of treated waste water are obtained per hour. The composition is shown in Table ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com