Anchor drilling jig provided with rod-protection mechanical hand and used for coal mine

A technology of bolt drilling rig and manipulator, which is applied to the installation of bolts, drill pipes, drill pipes, etc., can solve the problems of safety threats to operators, unbalanced driving and anchoring protection, and increased resistance of anchor drilling, so as to reduce the labor intensity of workers. , Improve the efficiency of anchoring protection and reduce the resistance of the protection rod

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The specific embodiment of the present invention will be further described in conjunction with accompanying drawing:

[0051] The present invention is a coal mine rock bolter with a guard rod manipulator specially developed to realize the function of the guard rod in the drilling process of the drill pipe, which effectively solves the working condition of the coal mine rock bolter in the anchor protection process, especially the need to connect rods Under the circumstances, the rod throwing problem caused by the excessive length of the drill pipe has greatly improved the reliability of the high-speed anchor drill of the drilling rig. It can be matched with the relevant rock bolter equipped with the airborne rock bolter.

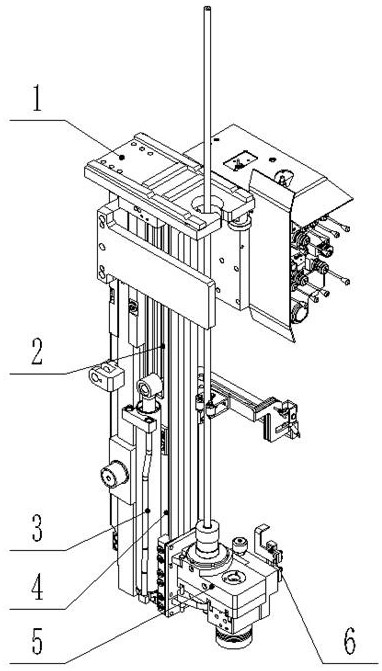

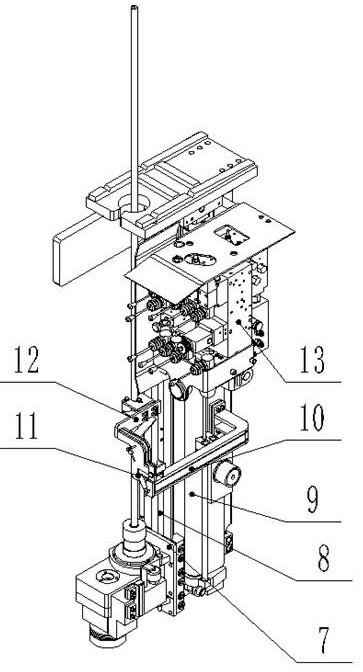

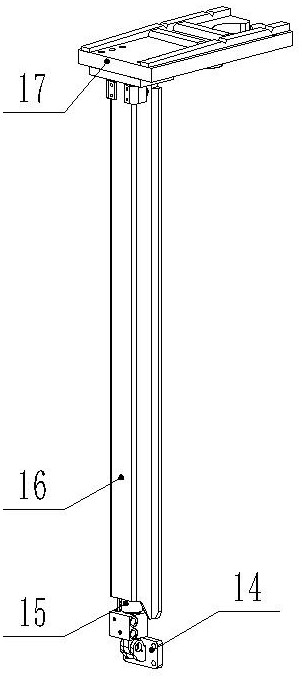

[0052] Such as figure 1 , 2 As shown, the present invention includes temporary support, frame assembly, short-feed oil cylinder, carriage assembly, drilling box, ejector rod hook-back device, guide connecting plate, chain transmission device, long-fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com