Method for calibrating pre-tightening force of external thread fastener with sensor

A fastener and external thread technology, which is applied in the field of pre-tightening force calibration of external thread fasteners with sensors, can solve the problems of not considering nut characteristics, redundant measurement parameters, low reliability of results, etc. The effect of various influencing factors, high calibration reliability, and simple calibration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to better understand the present invention, the present invention will be described in detail below in conjunction with specific drawings. Due to space limitations, Tables 1 to 4 in the present invention only extract part of the data in the actual experiment, not all the results in the actual calibration method.

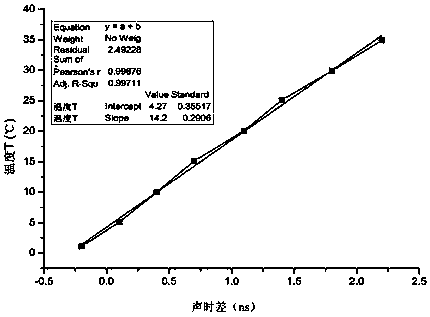

[0045] (1) Determine the temperature coefficient factor

[0046] 1. Test measurement

[0047] Put the bolt into the high and low temperature test chamber (the temperature control test chamber needs to have high temperature control accuracy and temperature uniformity) under the condition of no load. Confirm that the connection between the measuring probe of the ultrasonic measuring instrument and the externally threaded fastener to be tested is in good condition. Set the temperature of the test chamber as the reference temperature T0. After a certain time, ensure that the externally threaded fasteners reach thermal equilibrium. At this time, read the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com