An automatic transmission brake band test device

A technology of automatic transmission and experimental device, which is applied in the field of brake belt, can solve the problems of many interference factors, unfavorable performance of the single body of the brake belt, matching tolerance, etc., and achieve the effect of eliminating interference factors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

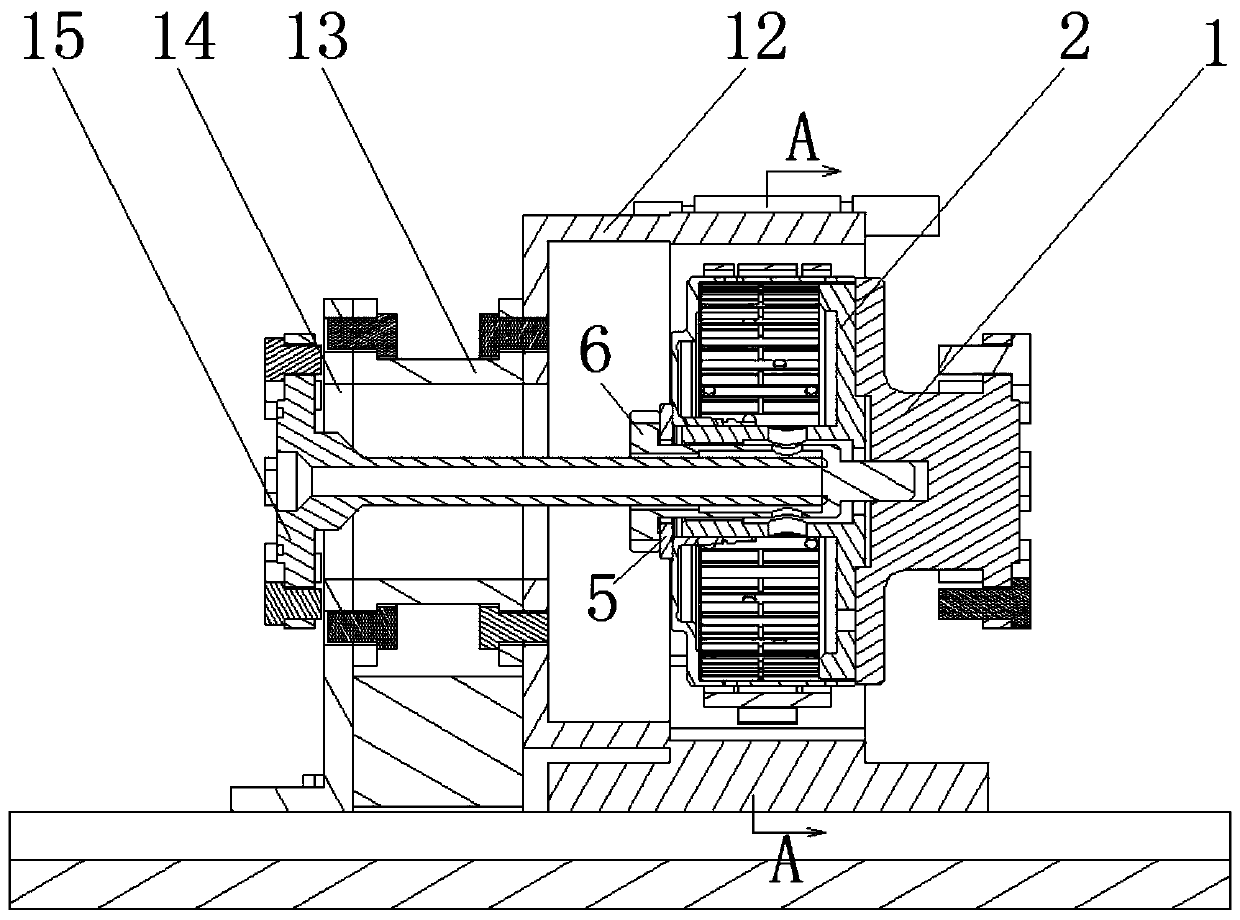

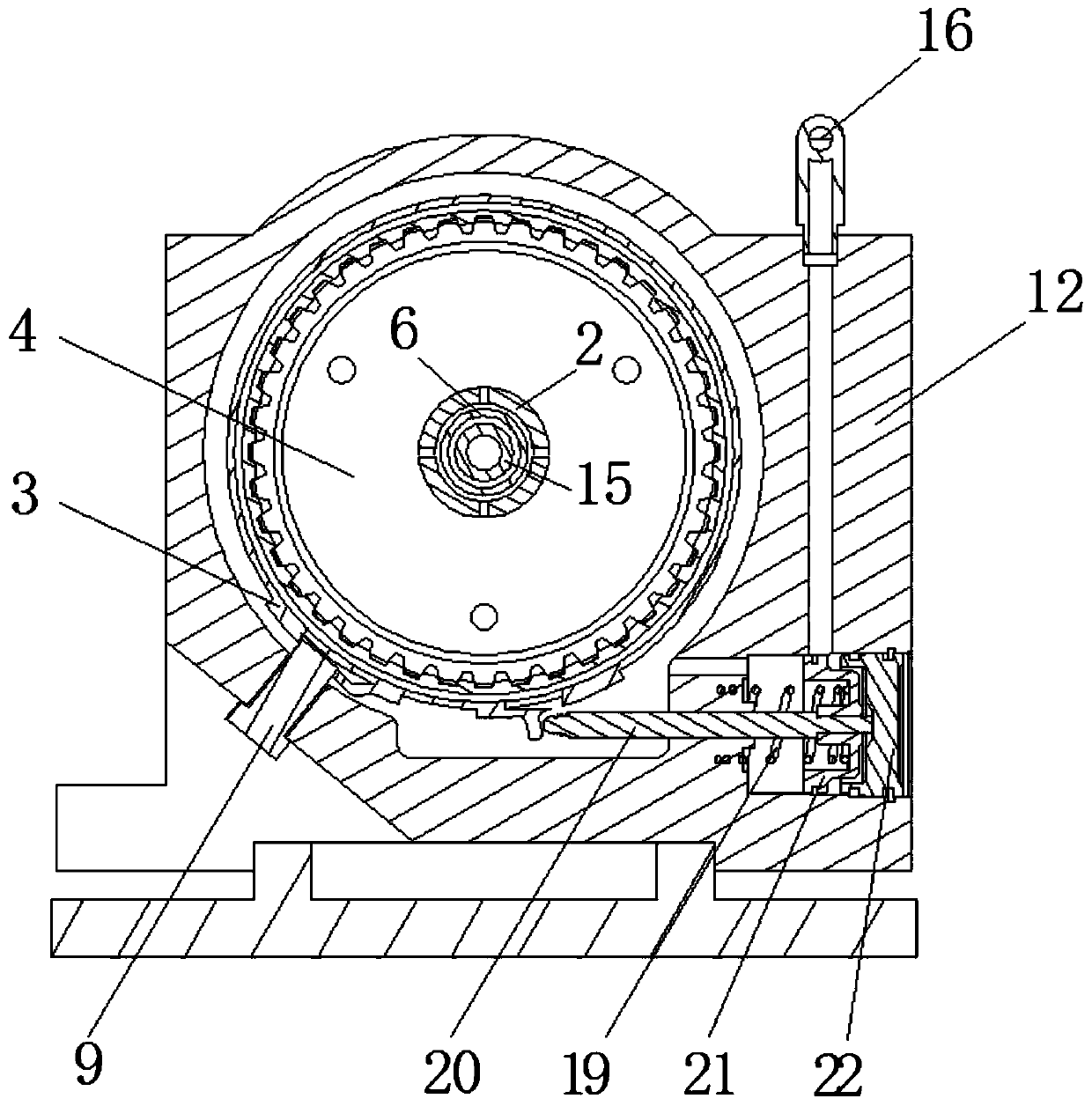

[0020] Combine figure 1 , 2 , 3 and 4, the present embodiment discloses an automatic transmission brake band experimental device, which includes a brake band 3, a clutch 4 and a brake pressure supply oil circuit 16. The brake band 3 is sleeved on the outside of the clutch 4. The clutch 4 is arranged inside the base 12. The right end of the clutch 4 is connected with the turntable 2. The middle of the turntable 2 is provided with a cylindrical shaft body, the shaft body is provided with a shaft oil hole, the clutch 4 is sleeved on the shaft body, and the turntable 2 is connected to the positioning Disk 1 is connected, and the right end of positioning disk 1 is connected with the rotating shaft on the platform. The rotation of the drive shaft on the platform drives the positioning disk 1 to rotate, the positioning disk 1 drives the turntable 2, the turntable 2 drives the clutch 4 to rotate, and the cylinder of the turntable 2 A fixing sleeve 6 is arranged in the cylindrical shaft ...

specific Embodiment approach 2

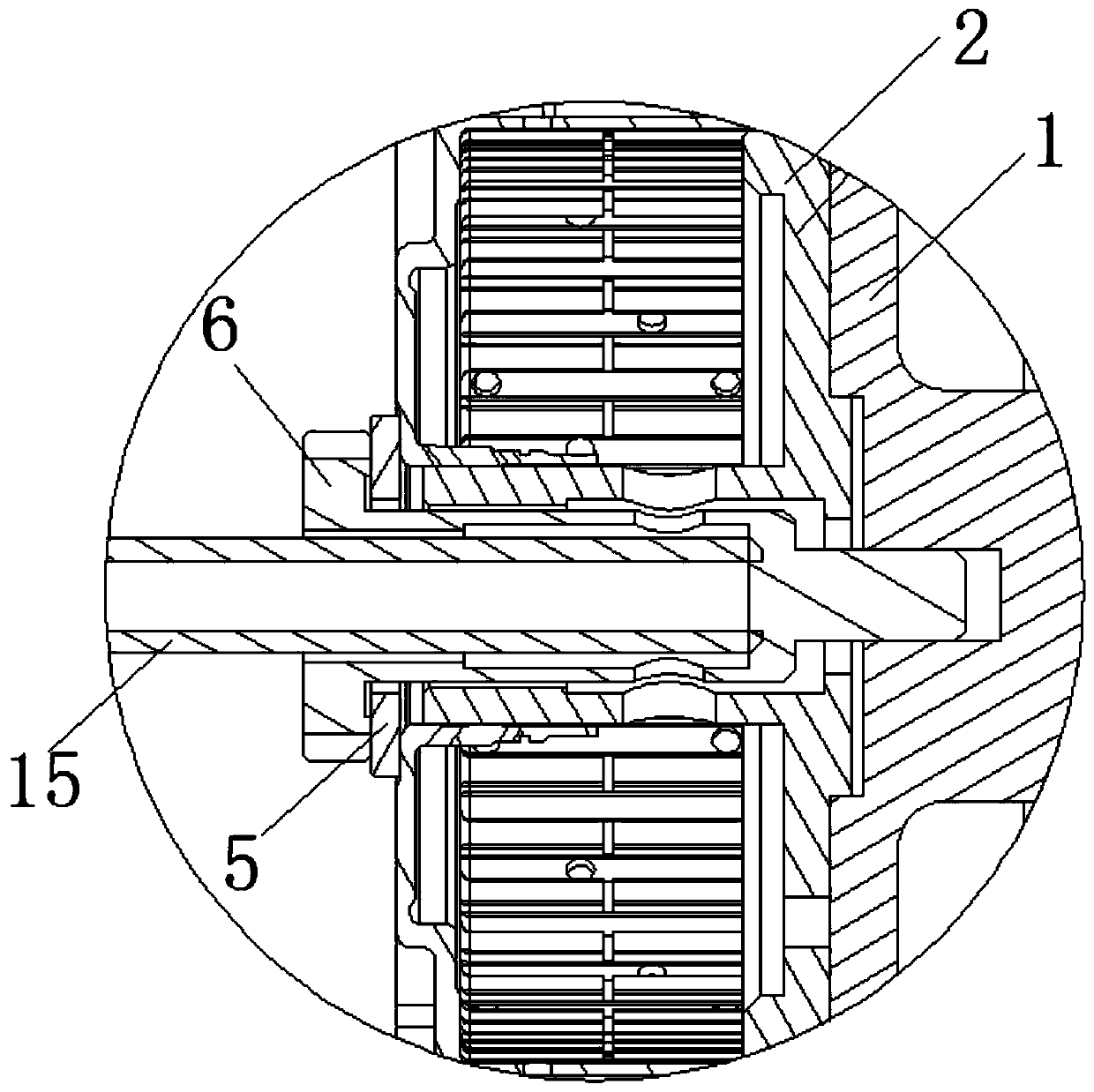

[0033] This embodiment is based on the specific implementation mode 1, combined with image 3 As shown, further, the end of the fixing sleeve 6 has a stepped outer edge, and a gasket 5 is provided between the stepped outer edge and the clutch 4.

[0034] The clutch is sealed by the gasket 5, and the axial movement of the clutch is placed at the same time, which improves the stability of the clutch operation and solves the problem of the clutch movement of the brake belt experimental device during the experiment, which reduces the contact area with the brake belt.

specific Embodiment approach 3

[0035] This embodiment is based on the specific implementation mode 1, combined with image 3 As shown, further, the fixed sleeve 6 is also provided with a fixed shaft, the fixed shaft passes through the turntable 2 and then is inserted into the positioning hole on the positioning disk 1, and the fixed shaft and the positioning hole adopt an interference fit.

[0036] The fixed shaft ensures that the fixed sleeve 6 and the positioning disk 1 are coaxial, thereby ensuring that the clutch 4 and the brake band 3 remain coaxial, which solves the problem that the clutch 4 and the brake band 3 have different axes and affect the experiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com