Compensation method of steel ball surface detect measuring system based on optical fiber sensing

A fiber optic sensing and measurement system technology, applied in measuring devices, material analysis through optical means, instruments, etc., can solve problems such as changes in the received light intensity of sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

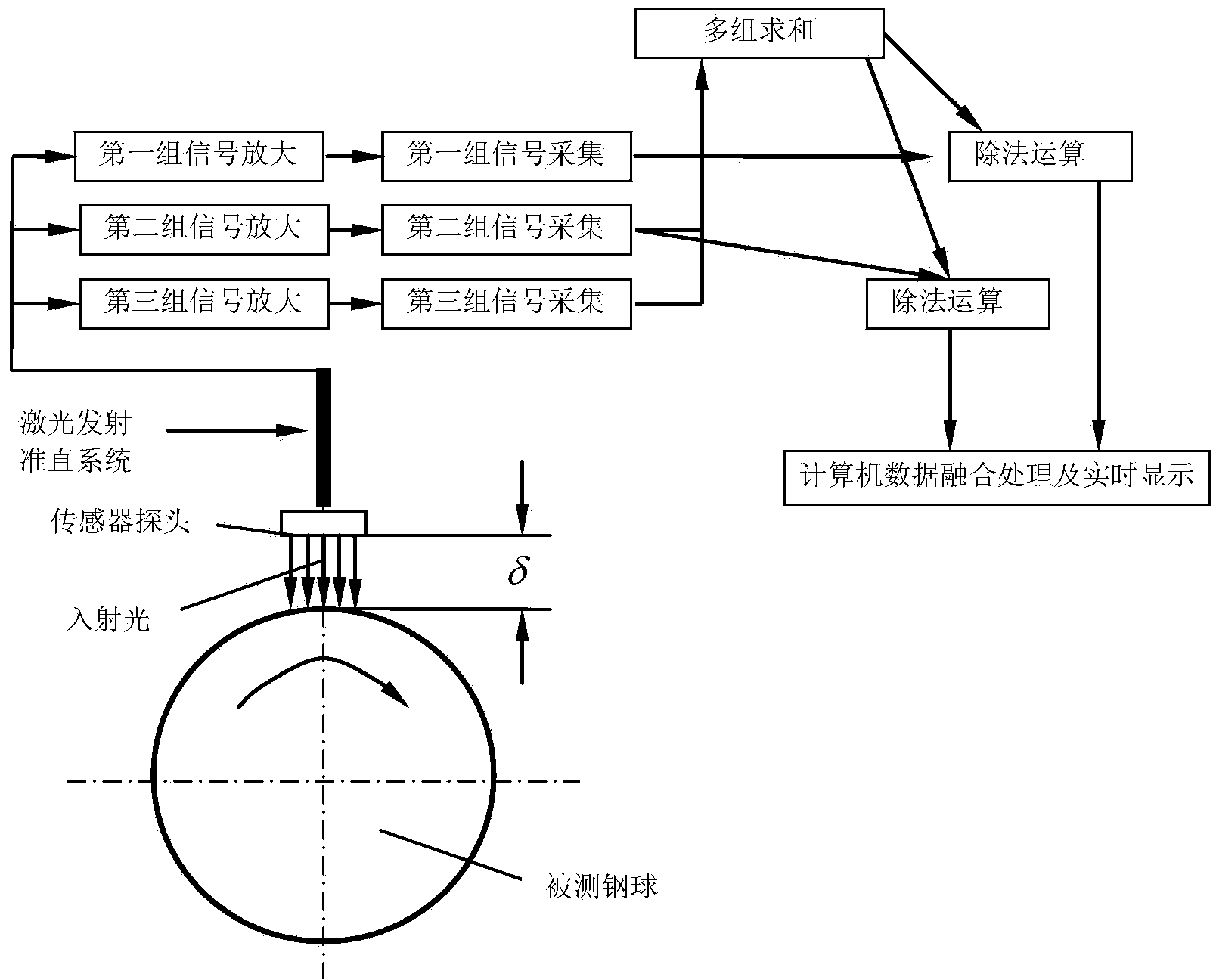

[0036] A compensation method for optical fiber sensors in the measurement of surface defects of steel balls, comprising the following steps:

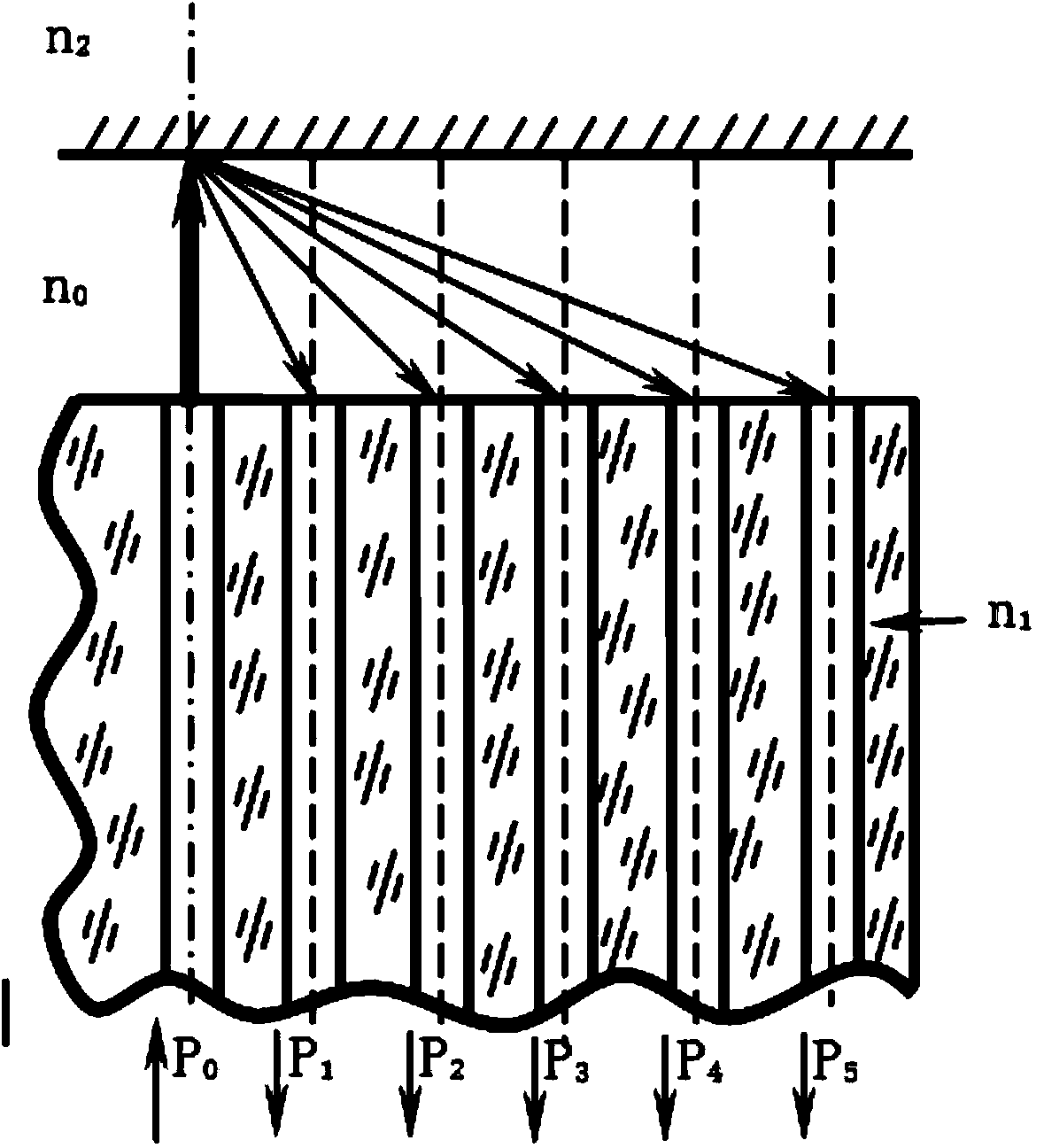

[0037] Step 1. For the sensor structure in which a single optical fiber emits and multiple groups of optical fibers receive scattered light, the incident optical power P is obtained by measuring with an optical power meter 0 And the corresponding optical power P received by multiple groups of fibers 1 ,P 2 ,...,P n ;

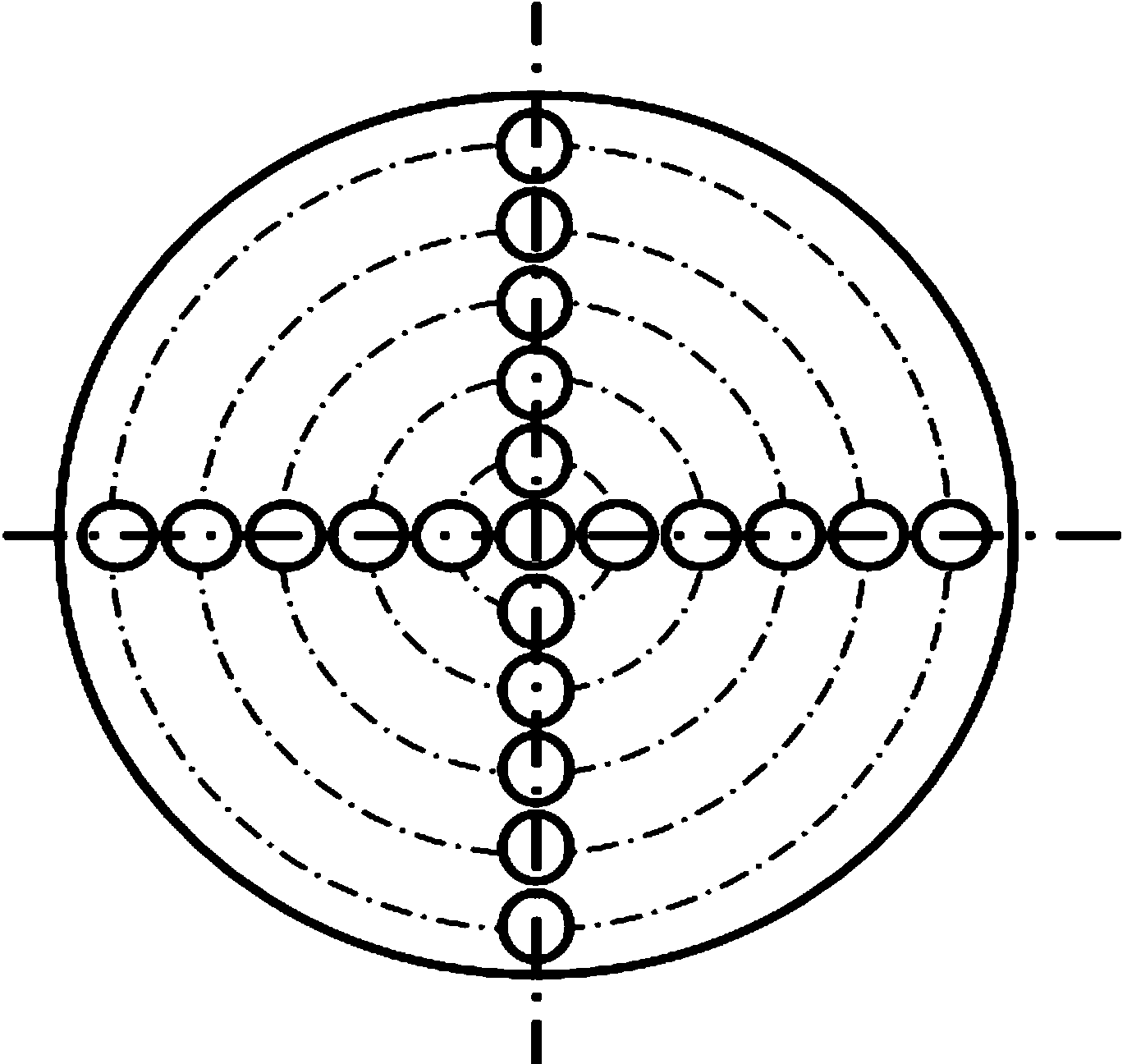

[0038] Step 2 versus the P obtained in step 1 1 ,P 2 ,...,P n Use multi-channel high-speed synchronous data acquisition boards for data acquisition to obtain digital signals of n-channel light intensity, according to figure 2 It can be seen from the structure of the optical fiber sensor that the reflected light intensity received by different groups of receiving optical fibers comes from different spherical micro-element surfaces. Since the surface of the steel ball is a curved surface, the inclination angles of di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com